Results 11 to 20 of 22

Thread: Emerald green hone?

-

06-06-2018, 11:12 AM #11

That is a Charnley or LI. If you can find any fleck or stripe or red, however small, it is 100% Charnley. Without examination and testing, it could be either. Looking at it, there may be an inclusion. You have to test it to understand whether it is a pinny inclusion (which could harm a razor) or just a superficial one.

-

06-06-2018, 11:17 AM #12

There are quite a few red specks and streaks.

It really doesn't matter if it's a CF or not but as I said earlier if it is I at least know it's a finisher. Will have to test it though.

As for the oil residue, do I need to continue to use it with oil?

-

The Following User Says Thank You to PMH For This Useful Post:

Toroblanco (06-10-2018)

-

06-06-2018, 11:44 AM #13

I'd say its a Charnley. Remember, not all are finishers, some I have heard are in the 8k region, which some consider to be a finisher, whilst others consider this range to be that of a pre-finisher. The many Charnleys I have tested however, have all been finishers. One gave a wildly sharp edge. I believe they work better with oil or glycerin. Or even with lather. They are oil stones, after all. Some prefer just water. YMMV. Enjoy, and congratulations on your find! I look forward to hearing how you get on with it.

-

06-06-2018, 11:47 AM #14

Oil it is then.

Will probably have an opportunity next week to try it out on a MK30.

-

06-06-2018, 11:55 AM #15

The MK30 would IMHO be a very good choice, as the steel I believe is harder than Sheffield Steel, for instance. IMHO, not all edges can take very fine Charnleys, or rather, are not improved/can be hurt by them. An example of this would be some British razors. Ironic, that a British hone isn't always great for British razors! You may not have known, but these large Charnleys and LI hones were as far as I can tell, never intended for, nor used for razors of their era. Rather, they were kept heavily oiled and used for chisels and other tools. The only reference I can find to the use of Charnley or other type of novaculite for razors, is for Rolls Razors, which was rare at that.

-

The Following User Says Thank You to Scipio For This Useful Post:

Toroblanco (06-10-2018)

-

06-10-2018, 11:33 AM #16

Honed and shaved with it today and it's definitely a finisher.

It keept the sharpness coming of 1u lapping film but mellowed the edge out a bit. The shave wasn't as smooth as I would have liked but I got impatient and shaved before showering which I usually don't do.

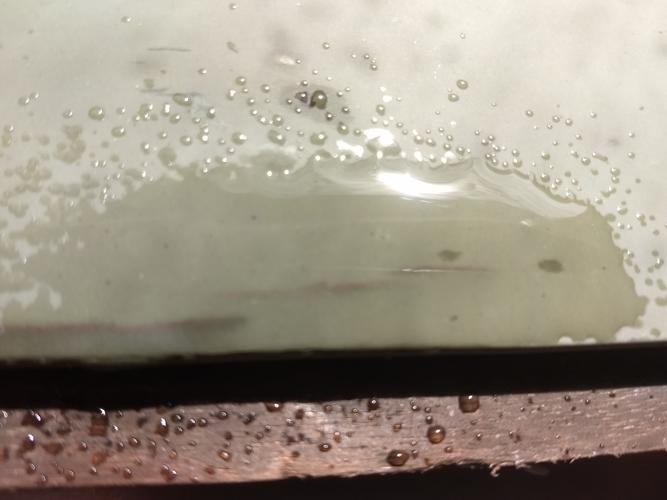

Just a question? How much oil are you supposed to use? Just enough to wet the surface or so much you create a wave when honing?

-

The Following User Says Thank You to PMH For This Useful Post:

Toroblanco (06-10-2018)

-

06-10-2018, 07:31 PM #17

On my hard oilstones I just make sure the oil is evenly spread, no oil wave. Let the oil do it's job. Just my 02. cents!

-

06-11-2018, 11:05 AM #18

How many laps did you do? These stones are extremely slow in my experience.

-

06-11-2018, 11:09 AM #19

Note sure, may by around 150?

Still waiting for my microscope so I can take a closer look at the scratch patterns.

-

06-11-2018, 11:29 AM #20

150 sounds about right! I haven't used a Charnley for a long time, but I remember they give very little feedback and one really has to know the stone and have experience with them as IMHO it hardly lets one know when the razor is 'done'. Thuringians and coticules which I use predominantly, are polar opposites. Small, soft and swift.

Possibly not always as fine though. They also readily raise a slurry. Some even auto slurry.Last edited by Scipio; 06-11-2018 at 11:31 AM.

16Likes

16Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote