Results 1 to 8 of 8

23Likes

23Likes

Thread: Arkansas hone

-

10-03-2018, 01:05 AM #1Senior Member

- Join Date

- Jun 2013

- Location

- Pompano Beach, FL

- Posts

- 4,047

Thanked: 636 Arkansas hone

Arkansas hone

Any idea about what grit an Arkansas hone usually is. Is it a good finishing stone.

-

10-03-2018, 07:04 AM #2aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Some swear by the black ones for finishers. About the only way to check it is compare scratch marks under magnification. Being a natural hone, nobody could give you an accurate answer, only a range. Coticules are a great example, I have had them to range from about 6k to 10k.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

10-03-2018, 08:28 AM #3Senior Member

- Join Date

- Nov 2016

- Location

- Chicago Suburbs

- Posts

- 1,104

Thanked: 292

Arkansas stones are rated by density and not by grit level. Typically, the more dense the rock, the finer the finish it will deliver. The most dense ones (either translucent or hard black) really doing more polishing/burnishing than steel removal.

-

10-03-2018, 09:05 AM #4

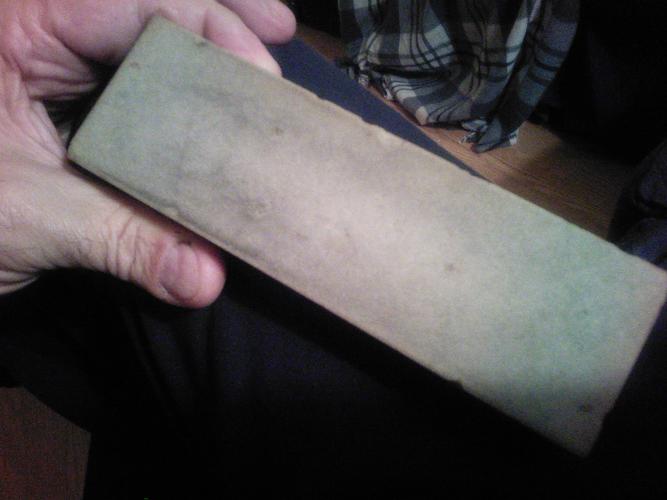

That one as pictured looks more like a soft Arkansas or a Washita. They make great-bevel setters; but as mentioned, you would want to follow it with either a finer translucent or black hard Arkansas to bring things closer to shave-readiness. Translucents lapped coarsely can remove steel fairly effectively, but when either they or black hards are polished smooth, they tend more towards burnishing.

Striving to be brief, I become obscure. --Horace

-

10-03-2018, 10:39 AM #5

The cool thing I found with the Washita and hard black, is how they perform with different lubes.( water, oil, glycerin, lather, ect.). My Washita can act like three stones, just as the black.

I burnished one side of my black, and left the metal swarf on the stone, to lessen its effects and make it a better finisher. Some time on a pasted strop yielded a nice shaving edge.

For the most part, I use them in a natural progression, instead.

Give it a good cleaning with some spray degreaser, lapp it, and give it a go. You might be surprised..!!Mike

-

10-03-2018, 05:17 PM #6

-

10-03-2018, 05:23 PM #7Senior Member

- Join Date

- Jun 2013

- Location

- Pompano Beach, FL

- Posts

- 4,047

Thanked: 636

I think you are correct. Now that you mention it I think there was a label at one time that said Washita.

-

10-04-2018, 02:14 AM #8

Yup. This. Arkansas and Washita stones cut with the spaces and not with grit. Like a cheese grater instead of sandpaper. They leave relatively wide and shallow cuts which is why they can cut much faster than the final edge they leave. I have a surgical black Arkansas that improves an edge off a 12k and I have a Washita stone that can set a bevel as fast as a 1k. Their cutting ability also depends on how deep the pits are and how jagged the rim around them is, which is why you get a finer acting stone after burnishing them and a faster cutting stone by refreshing the surface.

What a curse be a dull razor; what a prideful comfort a sharp one

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote