Results 1 to 10 of 12

Thread: Troubleshoot my honing mishap

-

08-19-2020, 09:53 PM #1Junior Member

- Join Date

- Aug 2020

- Location

- Missouri, USA

- Posts

- 27

Thanked: 5 Troubleshoot my honing mishap

Troubleshoot my honing mishap

Good morning folks. It's been some years since I've honed a straight razor so I'm having some issues troubleshooting this one. A coworker asked me to hone their Schrade Walden 65th anniversary razor but I'm having trouble getting it to even shave arm hair. I've advised him that it's not a great quality razor but he received it as a gift from a client shortly before they passed. Initial inspection using 60x magnification showed the bevel to be very thin and rough.

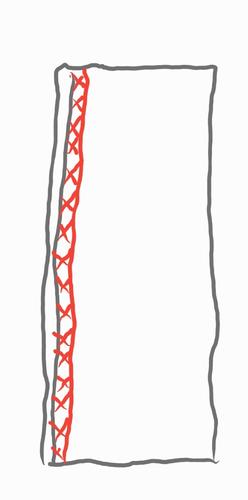

I've attempted to set the bevel at 1k and 4k, but no change in sharpness. Upon inspection it under a 60k loupe again it looks like the angle is off and honing the blade just behind the bevel. I've attempted to highlighted the section of the blade that seems to have been honed in the attached illustration in red. So I added a strip of tape and attempted setting the bevel with the same results. The highlighted section has grown and what I'm assuming is the factory bevel has shrank slightly. I then repeated the process with 2 and 3 strips of tape with the same results.

Figuring that I'm the problem I get one of my razors that needed refreshed, and had no problem shaving arm hair after 4k.

What is causing this? It does seem that the spine is considerably thinner on the problem razor even though their widths are the same. I've debated using additional layers of tape to better match the geometry or sticking with 2-3 layers and just keep working it at low grit until I see an improvement in the actual cutting edge.

Help my SRP! You're my only hope.

-

08-19-2020, 10:06 PM #2

By adding the layers of tape you are on the right track. The factory edge is just not right. Or as you said, the spine is too thin and the geometry is way off to start with.

If your dealing with a RSO then do the best you can. 3 layers of tape. Hog the edge a bunch, then kill the edge to take off some steel. Then hog the edge again until the bevel reaches the apex, replacing the tape as it wears out. Then remove a layer of tape and do it again. Measuring the bevel angle is a good idea so that you know what you should be shooting for in layers of tape on the finish of the bevel set. But if it never gets shave keen being an RSO, well, you have done the best it can get.

The other think that you could be doing is flexing the edge using too much preasure. If its a hollow blade it can flex easy. If its a near wedge than this is most likely not the issue.It's just Sharpening, right?

Jerry...

-

08-19-2020, 10:11 PM #3Member

- Join Date

- May 2010

- Location

- New York

- Posts

- 94

Thanked: 9

There are way more experienced people here than me, who I'm sure will chime in, but the two things that come to mind for me in this case would be either

A) your using too much pressure and causing the blade to flex, though this seems unlikely since you did fine with your other razor

or

B) could be he asked you to do it because he tried sharpening it first, and treated it like a knife, with the spine raised up off the stone, and put a crazy wide angle on it, and now you have to just keep going until the geometry gets back in line with the spine?

In its current condition, does the bevel or hone wear on the spine look exceptionally wide?

If not, i'd just keep going till i found the edge and made it right again (probably with a single layer of tape, to avoid excessive hone wear at the spine while correcting. Then, leaving it at that, or finish the process down to no tape one it's close would be up to your judgement)

Edit:

Lol looks like Gasman got in there while I was typing.

Nice to know my thoughts were on target hahaLast edited by Kavik79; 08-19-2020 at 10:13 PM.

-

08-19-2020, 10:34 PM #4

You could try lightly bread knifing the edge

"A Honer's adage "Hone-Shave-Repeat"

~William~

-

08-19-2020, 11:59 PM #5

It looks like it was honed off the spine , like a knife & I suspect it may not have a razor's geometry in the first place but even some new T.I.'s can come like that.

3 layers of tape should surely have got you onto the edge tho.

Good advice in above posts. Would be ideal if someone near you could take a look .The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

08-20-2020, 12:48 AM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Not sure that was designed as a shaving razor, more of a collector piece. It was also made early in the production of Chinese razors, when they were very rough and poorly made, (2010-11).

Sounds like it may have had the edge ground with the spine off the stone.

With 3 pieces of tape you could get an edge on it, just do circles with pressure to get the bevels to meet. Get the tape on as tight as you can and replace it once it starts to get squishie.

-

08-20-2020, 05:34 AM #7

So here's a problem.

A bit of googling shows these are labelled as 400 stainless which can mean any number of grades.

Trouble is 440C would probably be the best so you'd think they'd boast it if that was the one they used.

Also these were made in China & not by Henckels who know how to make a good stainless razor.

My guess is it's 440A & will have large carbides & an uncomfortable shaving edge if you can get it to not chip. Probably not what you want to hear but hey! I could be wrong.The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

08-20-2020, 09:51 AM #8

RSO from China is what I was thinking too but if a guy want to spend the time to hone it...

It wont be a smooth shaver but you can make it sharp. One way or another.It's just Sharpening, right?

Jerry...

-

08-20-2020, 02:00 PM #9Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Some of those 400 series blades from China during those years will never get sharp. I'm serious. The heat treating on them was so bad that they simply won't get sharp. It was either a terrible heat treating, or they simply lied about the steel type. The ones with the Schrade name on them were notorious for that. You could get the carbon steel blades sharp, but they would dull quickly. The stainless blades would never even take an edge. The same problem can be found in the knives from Pakistan to this day.

-

08-24-2020, 09:34 PM #10Junior Member

- Join Date

- Aug 2020

- Location

- Missouri, USA

- Posts

- 27

Thanked: 5

It seems like this is the winning answer.

I applied 3 layers of tape before working it for way too long on a ~500ish grit until the new honing met the cutting edge. Then I worked my pyramid through 1k, 4k, 8k, and 12k, stropping lightly on bare linen between grit. While razor has a mirror finish at 60x magnification, there ever so slight chipping all along the cutting edge only just visible. I've been unable to get it to show on picture though. Next time I go into the fiance's clinic I'll have to photograph it off one of their microscopes. I'll have to return it to my coworker as a damn sharp box opener but a very poor excuse for a razor.

Thanks for all the help gents.

21Likes

21Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote