Results 1 to 5 of 5

Thread: Help Identifying my stone

Threaded View

-

10-26-2020, 03:20 AM #1Senior Member

- Join Date

- Jul 2010

- Posts

- 120

Thanked: 14 Help Identifying my stone

Help Identifying my stone

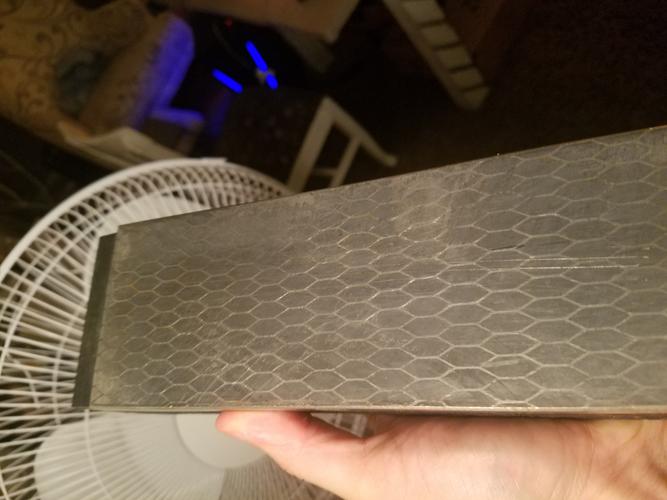

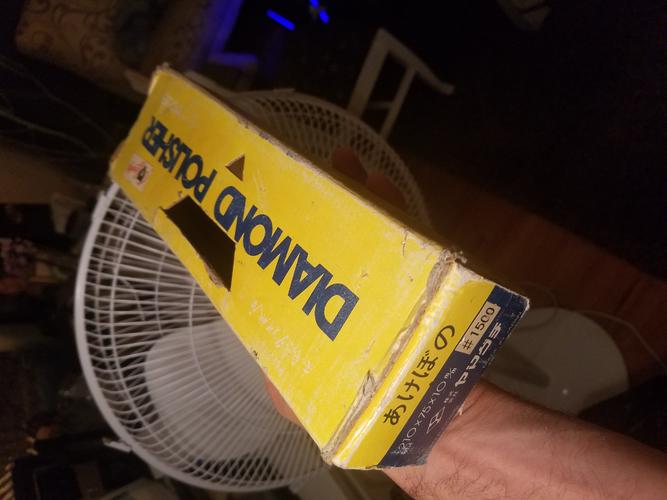

Picked this up for $10. Seemed like it could be worth it for a diamond stone - although I don't know much about them.

The box is marked #1500 - which, after feeling the stone seems WAY to low. The stone almost feels like a finishing stone. Does that mean it's completely worn? Or is that just how diamond stones feel?

Otherwise, does anyone know what kind of Diamond stone this is?

4Likes

4Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote