Results 1 to 10 of 18

-

03-03-2021, 06:04 PM #1Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215 IT’S ALIVE, Saving a Snow White 8K

IT’S ALIVE, Saving a Snow White 8K

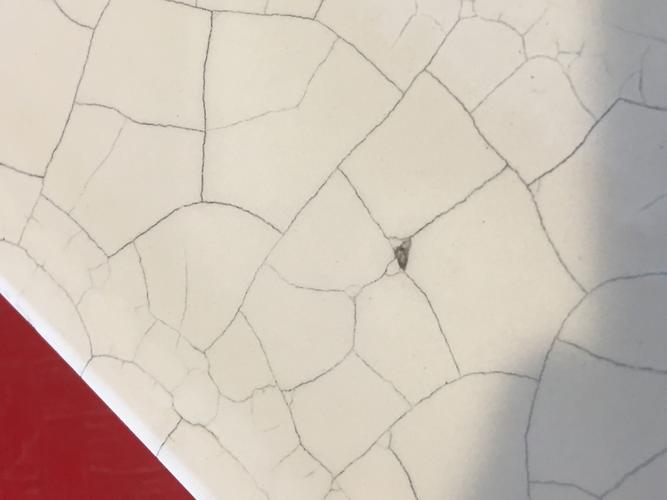

My 8K Snow White has been crazed for years. it is several years old and even crazed can produce an edge similar to my 12k Super Stone.

A couple years ago I purchased a new stone anticipating the stone would become unusable. Actually, I bought 2, one as a backup.

Today as I was honing on it, I felt a click, heard a Tink and saw a small divot in the middle of the stone and chip in the edge. A while back another chip/divot appeared near one end, but I have been able to avoid it, still it got a bit larger.

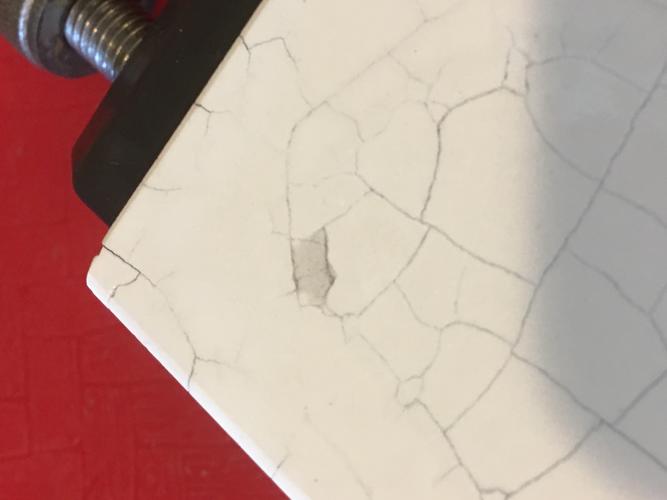

So, I cleaned up the holes, (running water and toothbrush) and filled the two divots with CA and glued a few of the larger cracks, even though they could not be felt while honing or with a fingernail. Let cure for a few hours and lapped flat with a 300-grit and 1k diamond plate.

Honed on it and it is just a good as it always has been. I cannot feel the glued divots or any of the cracks and they do not chip the edge. I have tried the new Snow Whites and they produce nice 8K edges, but not mirror finished like the old 8K.

I have CA glued natural stones, but never a synthetic and not a crazed stone. We will see if it lasts. I sure hope so…

If you have a crazed Naniwia, all is not lost, give it a try, what do you have to lose?

First pic is pre cleaning and gluing, the rest are after lapping the small center chip is about 2mmx2mm and the larger 6mmx4mm.

-

-

03-03-2021, 07:58 PM #2

I thought like you until my 5k gently nudged into a jnat.. ..Jnats will always win ..

-

03-04-2021, 01:40 AM #3

-

03-04-2021, 07:56 AM #4

I did glue mine back together with J B weld, it seems fine although I'm done with it.. and I took the opportunity to try an epoxy seal around the sides and bottom.. Definitely the worst seal I've tried, Urushi being the best.

-

03-04-2021, 11:43 AM #5Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,811

Thanked: 562

-

03-04-2021, 12:05 PM #6

-

03-04-2021, 01:42 PM #7Senior Member

- Join Date

- Sep 2010

- Location

- North Central florida

- Posts

- 213

Thanked: 30

-

03-04-2021, 03:31 PM #8Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I did dry it with a microfiber and waited about an hour.

Moisture will make CA kickoff faster. An old modelers trick is to breath on a CA glued joint to get it to kick off.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

32t (03-05-2021)

-

03-04-2021, 04:48 PM #9

I wonder if one could squeegee the whole top surface with CA to get it down into the checking and then lap it.

-

03-04-2021, 05:33 PM #10Senior Member

- Join Date

- Sep 2010

- Location

- North Central florida

- Posts

- 213

Thanked: 30

How about a layer of epoxy and then either a pressure pot to force it into the cracks or a vacuum chamber to to pull the air out and replace it with spoxy. I have a pressure pot setup.

23Likes

23Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote