Results 11 to 18 of 18

-

12-10-2009, 10:05 PM #11Senior Member

- Join Date

- Apr 2009

- Posts

- 786

Thanked: 132

And what if, ya already have alot of vintage Eschers, but no Beryl hone? LOL.

I think Sham just wants to add some color to his massive collection...Beryl, is kindof a xmas-y color, no?

Beautiful hone Sham...ive seen it on ebay for some time...even added it to my watch list for awhile.

Be cool to hear how it hones.

Many thanks,

Mac

-

12-11-2009, 09:47 PM #12

If I had to make an educated guess from the picture

I would call this a "Chlorite rich quartzite". If it is, it

would hone a lot like a black Arkansas or perhaps a

translucent Arkansas hone. The green chlorite mica

may help keep the grain size of the quartz fine and

available as a cutting media.

I do hope someone with a lot of comparison hones gets to try

one of these. The differences between the possible mineral

compositions are large. However, that does not matter

when the proof is how good a hone it makes.

P.S: I do not think the green is kryptonite which would fog

old style film but who knows in this digital world

-

12-11-2009, 11:28 PM #13

IMO, that's a pretty big gamble (he says he has 10 now, maybe make an offer?), but then again, I don't have HAD...

-

12-11-2009, 11:57 PM #14

No matter how many men you kill you can't kill your successor-Emperor Nero

No matter how many men you kill you can't kill your successor-Emperor Nero

-

12-12-2009, 12:30 AM #15

-

12-12-2009, 03:21 PM #16< Banned User >

- Join Date

- Feb 2009

- Posts

- 55

Thanked: 17

I used to polish my gravers on a small Beryl slab - worked perfectly. I now prefer ruby for my gravers.

-

12-14-2009, 12:14 AM #17

-

12-24-2011, 07:46 AM #18Junior Member

- Join Date

- Nov 2011

- Posts

- 1

Thanked: 2

I thought sharing my experience with the beryl sharpening stone might help someone (as your hints on this forum help me).

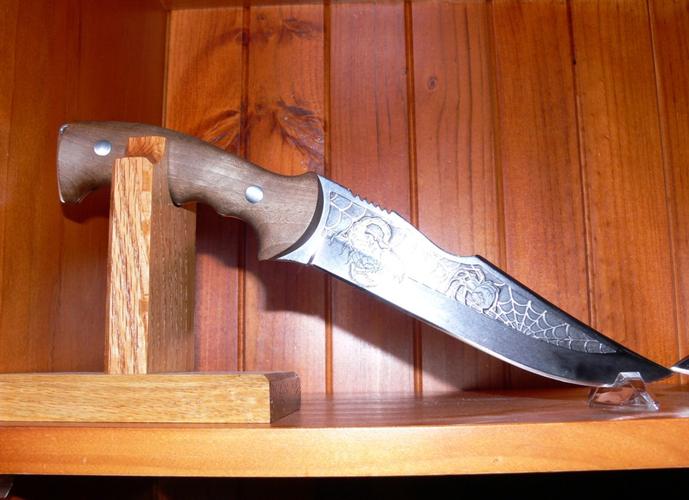

I wouldn't even have looked at it if wasn't asked to sharpen a problem knife you see on the photo. The knife is heavily etched and previous sharpening brought the cutting edge to the very etching, better seen on the close-up photo.

The edge looked even, but was blunt, hardly shaving forearm, and tearing paper. As per the manufacturer, the blade is of "French High Carbon Z60 steel".

Because of the etching I had little room for resharpening and no room for experimenting. I went through my stones looking for one that would be agressive enough to form a burr, fine to cut off bare minimum of metal, and hard not letting abrasive particles dragged onto the etching in fear of scratches; ideally it should have been cutting, polishing and producing no slurry all-in-one.

I picked Translucent Arkansas and Spyderco ultra fine ceramic bench stone.

I hardly started with the Translucent Arkansas, when noticed it gave a mat surface to the edge, encroaching upon the decorative etching; should I have continued, I risked grinding off the bottom of the engraving.

I switched to the Spyderco ultra fine ceramic stone, which is finer than Translucent Arkansas, and it seemed to be both cutting and polishing well. I formed the burr alright, but to my surprise couldn't thin it off; I tried again from start, but as soon as I began alternating blade sides to thin off the burr, it just dulled the edge.

It must have been due to the 'Z60 metal' used in the blade, as I am regularly using ultra fine ceramic for thinning off the burr on other carbon steels, Muela molybdenum-vanadium and damascus.

Puzzled, I searched for another hard ultra fine stone (and BTW that's how I found your forum) and decided to give Beryl a try. The eBay seller 'merlintools' wanted for the biggest beryl stone about $270, but took my offer of $200. With natural stones, the bigger the stone, the better is its quality. I also bought a smaller one for lapping, but this wasn't needed. The stone I got required no lapping, though its surface had circular saw marks which you probably are able to see on the photo, of no effect on sharperning.

"Natural Beryl Polishing Stone Graver Sharpening Tool"

To maintain even angle, I used the stone on a wooden wedge, the idea borrowed from this guy on youtube:

Sharpening II 012 - YouTube

I was sharpening on the beryl with a drop of honing oil, blade back first; a tangible burr formed after 40 laps of one side of the blade, then I did the same amount of laps on the other side, thereby shifting the burr to the opposite side, and then thinned the burr off by lapping sequence 20 laps one side - 20 other, 10 one side - 10 other, 5-5, 4-4, 3-3, 2-2, 1-1, and finally, did 20 laps more alternating sides.

At this stage, the blade was splitting a daughter's hair.

To finish, honed with Inigo Jones Welsh slate (Dragon's Tongue), no slurry, just soapy water - 40 laps alternating sides.

From this experience, I can confirm the seller's claim of Beryl grit as 8000 (Japan), i.e. about 1-2 micron, which is 3 times finer than Translucent Arkansas, and 2 times finer than ultra fine ceramic, of like hardness.

I then tried the Beryl stone on another hunting knife you see on the photo next to the wooden wedge support, in the sequence: edge first on Ceramic FINE (5 micron) bench stone, then back first on Translucent Arkansas (4 micron), Beryl (1-2 micron), and Welsh Slate hone (Dragon Tongue), with the same satisfactory result.Last edited by vadim; 12-24-2011 at 11:21 AM.

The Following 2 Users Say Thank You to vadim For This Useful Post:

Havachat45 (12-25-2011), Noswad (12-28-2011)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote