Results 11 to 20 of 20

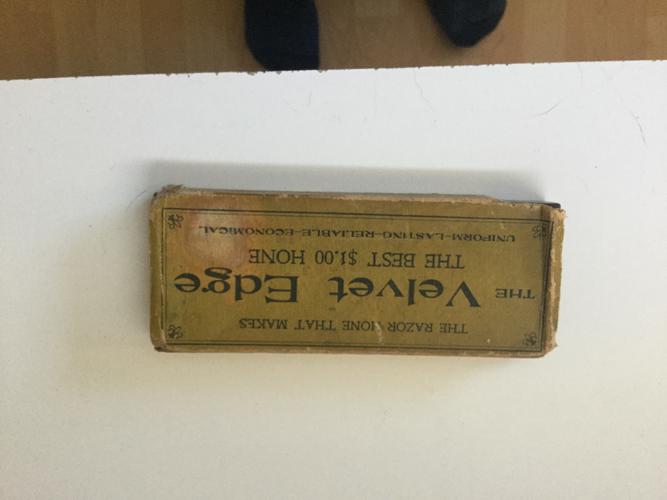

Thread: velvet edge hone.

-

02-01-2011, 09:01 AM #11

Velvet Hone

Velvet Hone

I'm glad to find your thread. I found one, and purchased it without much thought. It was very inexpensive. Not sure if your model is the same, but mine's got a V shaped top, and the bottom is flat. The seller noted the V shape is for single and double edged blades, while the bottom is for my beloved straight edge.

I think the term "velvet" is related to the texture of the stone. I makes me think of a soft brick with less pores. it's feels almost clay like.

I figured "cool, multipurpose!" The texture is almost chalky. almost like a wet brick, but not exactly. any time I touch it, my hands get a small amount of red power on them. Nothing severe, I just think it's because no one used it for a long time.

My straight edge was already sharp, so I didn't want to waste the metal. I did have an old double edge, so to the hone it went. about 50 passes, and the blade was shave ready. I don't yet know how to hone a double, unless I use my palm. I tried it, but noticed no difference in shaves.

Basically, The hone is awesome. I wouldn't say it's like a swaty or carborundum razor hone, but it's good in it's own right. The size is small, but I think my model hone is really more intended for the single/double edges.

Once my razor needs a maintenance hone, I'm going to bring it to the velvet hone first, just to test it out.

I would buy more of these cute little things, just for the size, not yet knowing how it performs on my main shaver. If it really does as well as people say, I'd be even more inclined to buy every singe one I see in the future.

-

02-01-2011, 09:14 PM #12Citizen

- Join Date

- Apr 2006

- Posts

- 246

Thanked: 55

The use of the term "velvet" I believe refers to the type edge the marketer wanted you think the hone imparted. The term "velvet edge" was a term commonly used to refer to edges made by a Belgian Hone. I have an example of this phrase being used to sell Belgian Hones themselves as it was stamped right on the rock itself referring to it's "velvety edge" that "only a Belgian stone" could provide.

So it may be that the marketer of the "Velvet Hone" wanted you to believe that is was as good as a Belgian coticule while being a fraction of the cost.

Your hone may or may not work well depending on what it is made from and how well it was constructed. I've run into a few that are rubbish or that have deteriorated to the point of crumbling while in use and chip like mad. Seeing red powder on your hand may be an indicator that it is starting to deteriorate or it may just be the dust left over from when it was manufactured and stored.

I highly recommend you use it on a practice blade and then view the resulting edge under a microscope. And it would probably do well to actually examine that edge under a microscope before you use the hone just to get an idea of what that hone will actually do to that edge.

In their day they were great little stop gaps allowing barbers to literally touch the razor up between shaves on customers. Nowadays though there are better tools available. Some people really like them though and the really well made variety are still quite serviceable. Hopefully you got one of them.

Best Regards,

EL

-

02-03-2011, 03:43 AM #13

I'm glad you asked this as Ive never seen an explanation either,If you were breaking out the stones,and were missing one-where would the barber hone fit in the progression?

And why aren't they used instead of a high grit stone instead of buying one,can a Swaty be used as a 10k stone,as you go up the ladder? I'm aware that there used as a touch up stone,but you can use coti bout also,this is a different question.

thanks

-

04-08-2017, 01:11 AM #14

-

04-08-2017, 01:00 PM #15

I'll have to say, hats off to whoever came up with the name 'Velvet Edge' for a straight razor hone.

-

04-18-2017, 05:31 PM #16Senior Member

- Join Date

- Aug 2014

- Location

- East Central Illinois

- Posts

- 782

Thanked: 101

I have several Barber hones & two tht stand out are my Raven & the John Primble. I have used both as finishing hone with great success. The J. Primble may be just a little nicer in the honing Dept. but it is really hard to tell. On another razor forum there is a "Barber Hone Shoot Out" where many barber hones are tested.

Slawman

-

04-18-2017, 08:28 PM #17

i have about 5 different barbers hones and have not found one that i like. Just like has been stated already "when the razor starts to seem dull is the time to use it" i have found that it always takes more than the recommended 2-3 strokes to make a difference and than it is always a scratchy rough feel, rather than an improvement. always make visible scratches on the edge. is that commons? (i'm actually thinking of selling them since i don't use them anyway).

-

The Following User Says Thank You to tintin For This Useful Post:

Papabear11 (05-18-2017)

-

04-18-2017, 08:56 PM #18

All barber hones are not created equal. There are many that are very well suited for their intended purpose. A partial list of some that I have found to work very well includes: Lakeside, Frictionite, Special no 500, Panama, Apart, the above mentioned John Primble, Fernsler Ruby, Gem Cushioned and the list goes on. Modine has done great work over at Razor and Stone reviewing barber hones and taking much of the guess work out of it.

-

The Following User Says Thank You to Lazarus For This Useful Post:

tintin (04-19-2017)

-

04-19-2017, 02:55 PM #19Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Depends on the stone. My Swaty is about 8K and leaves scratches about like a Norton 8k - visible in the right lighting. I have others that are finer and improve an 8K edge. Then I have a glass hone that changes performance based on what kind of slurry is used with the hone. Quite an interesting little creature that bucks the assertion that barber hones are good for maintenance but not for honing. I can make an 8k edge with barely visible scratches, a hazy edge, or a 12K+ edge with the glass stone.

They're just something you have to tinker with and learn individually. Small tip, a little bit of wet shave lather can go a long way with a barber hone. I've used that trick with most of mine and get a pretty good edge. I usually do 5 to 10 licks, then check the edge if I'm just going for a refresh. If unhappy, then I do 5 to 10 more and so forth until it's as good as I can squeeze from the stone.

I'll second Slawman on the Raven stone. The Celtes is equally good, I suspect them to be made in the same factory perhaps for different distributors. I also have a 2 sided Pike that's decent, if a little on the small side.

-

05-18-2017, 09:23 PM #20

9Likes

9Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote