Results 11 to 18 of 18

Thread: Caborundum 102- ??????

-

04-01-2011, 11:31 AM #11

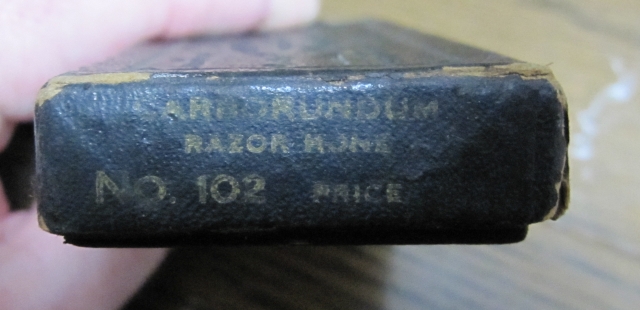

Gentlemen, the box certainly says razor hone.

It's right at 10cmx3.7cm, or about 4x1.5 inches.

In addition, I also just got a 103 (this one is stamped 103 razor hone on the stone). It was slightly dished, so I lapped it out before I tried it. Comparing the scratch patterns from the stone, the 103 was much MUCH finer, so I reckon something's amiss.

I didn't lap the 102 at first, just scrubbed it with alcohol, acetone and a stiff brush.

Thinking this might not have been enough, I lapped one side.

I have not yet tried the lapped side, so there might simply have been something on the unlapped surface of the hone.

-

04-01-2011, 12:00 PM #12

Can't help you out with your 102 but I do have a 103 which I'm very pleased with. Did you have a stone stamp on your 102 or just a box stamp? Both came stamped on mine but cleaning the hone removed the stone stamp.

Last edited by SewerGuy; 04-01-2011 at 12:03 PM.

-

04-01-2011, 12:39 PM #13

I'd wager the stone and the box are perfect matches. The stone just needs a little lapping love. =)

Enjoy,

Me

-

04-01-2011, 04:22 PM #14

if you use Carborundum stone on a blade which finished on Japanese or and Escher before your blades edges will have saw tooth if you inspect the edge under 100x magnification.

Let me explain a little more.

when you hone the blade on finishing hones(japanese ,Escher etc) usually end of the honing you will have perfect straight line edge.

if you instead of finishing stone use carborundum stone you will not have that line. you will have saw tooth edge?

This is what happens(my thinking)

You check the edge under magnification and see the edge similar to 1k level(saw tooth) and this is confuses you.

You think every single time when you check the edge if you see saw tooth that means edges level in 1k around.

In reality it is not so.

you would have saw tooth on 1k level or 8 k level.(this will make you more confuse).I fully understand this is new for most of You.

Now if you pick up 8k level saw tooth edge and shave with it you will be fine.

Excellent example to this will be Turkey oil stone.

when you use that stone edge will form saw tooth but that edge will cut similar to 8 k level edge.

hope this helps.Last edited by hi_bud_gl; 04-01-2011 at 04:25 PM.

-

04-01-2011, 08:09 PM #15

A lot of insights here.

A stone whose abrasives are low in Mohs hardness(stone medium can be dense but without abrasives being hard enough) can polish the edge without sharpening it in a lasting manner(some barber hones). A stone containing abrasive of higher hardness can sharpen the steel in a lasting manner without giving a mirror polish(the natural material corundum, the purest form of natural aliminium oxide stone could be an example for this).

Vaseline idea sounds interesting.Last edited by ferroburak; 04-01-2011 at 08:13 PM.

-

04-01-2011, 08:25 PM #16

Carborundum stone involves some type of pressure chamber for its abrasives' processing combined with a sintering process. It would be still a challenge to control the pressure chambers to continuously get the desired hardness for the material. The homogeneousity of the crude abrasive in size and hardness could be desirable for better results. In short, this could be simply be a bad apple.

Last edited by ferroburak; 04-01-2011 at 08:28 PM.

-

04-02-2011, 04:23 AM #17

I have to go along with this post, I have both. The 103 is the finer of the two and is the only thing that will make an edge on a no name solingen I have. The 102 seems to be a good bit coarser than the 103. The earlier post of using petroleum jelly or lather might make a great deal of diference. The 102 seems a bit smaller in size than the 103; if only by a couple mm.

Respectfully

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

04-02-2011, 10:45 AM #18

Sham,

As I said, I tested the stone on a razor finished on a 12K artificial hone, not on a natural hone. The scratches were very coarse, and the razor would no longer cut--I don't automatically assume that the razor is 1K based on anything other than that the razor wouldn't cut, and in order to hone out the scratches at all I had to drop back down to 5K.

None of this is new to me, except the idea that a barber's hone would be so destructive to a razor's edge.

I've since lapped the (presumable) 102, and while it has helped I still find it much coarser than the 103.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote