Results 1 to 10 of 10

Thread: Swaty barber's hone

-

04-11-2012, 01:56 PM #1

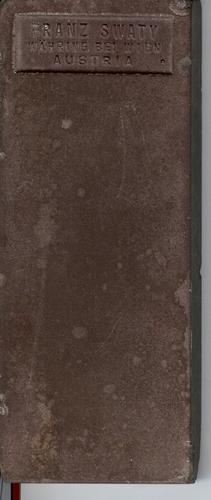

Swaty barber's hone

Swaty barber's hone

A local retired barber gave me his hone. From what I can find with searches it is a great hone. It is quite chipped on both sides. Advice on care/and removing chips would be nice. I'm still shipping my razors out for a honing (still learning to shave, honing will tackle later), and i'd like this to be usable when I am ready to touch up with a hone. Note also says "SRD" on the left edge.

-

04-11-2012, 02:14 PM #2

my opinion:

get a 12x12 granite or marble tile from the hardware store and a couple of packets of wet/dry sand paper 200, 400 and 600 at least. lap only the back side smooth by wetting the paper and sticking it on the tile and then do figure 8's with the swaty you might want to clean up the front a little but getting that smooth might endanger the logo so do not lap that too much. when the chips are gone with the 200 then smooth it with the 400 and 600. that is just what i would do.

you may find doing this in a sink of water or under running water will help keep the swarf from clogging the paper so fast. it will take a while and maybe a coarser paper would be better to start with.

jim

-

The Following User Says Thank You to syslight For This Useful Post:

JayhawkPharmD (04-11-2012)

-

04-11-2012, 05:17 PM #3Senior Member

- Join Date

- Mar 2011

- Location

- Washington DC Metro Area

- Posts

- 468

Thanked: 114

I've lapped my two Swaty's using the above method. Be prepared for it to take a long time. :-)

-

04-11-2012, 05:30 PM #4aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

From those photo's, it looks like there are a lot of pores/pitting to the surface...is this so? If so, you may have to start at a much rougher grit and work your way up as a barber hone should appear VERY smooth. You will have your work cut out for yourself as those stones are REAL hard. Messy and labor intensive, but worth it in the end. Use a lot of water to keep the sandpaper cutting and not "mudding" up.

-

04-11-2012, 09:32 PM #5

-

04-12-2012, 08:45 AM #6Senior Member

- Join Date

- Feb 2012

- Location

- Victorville, CA

- Posts

- 112

Thanked: 10

I just lapped my Swaty with a brand new DMT D8C. Flattened the Swaty and broke in the DMT as well as smoothing both, all in one fell swoop. It didn't take too long, either. Much quicker than the sandpaper route. Luckily, my Swaty has no chips in it.

-

04-12-2012, 10:37 AM #7

I would lap both sides with sanding paper starting with 120 grit to 1k-2k grit and only smooth the edges of the chips with a strip of sandpaper. Barber hones will wear a DMT relatively fast.

-

04-12-2012, 01:36 PM #8Senior Member

- Join Date

- Feb 2012

- Location

- Victorville, CA

- Posts

- 112

Thanked: 10

-

04-12-2012, 03:06 PM #9< Banned User >

- Join Date

- Feb 2011

- Posts

- 1,256

Thanked: 194

I am starting to really like barber hones...since I usually only need to touch up my new razors I don't have much need for other stones that set bevels and what not. My barber hone works amazing to touch up my edge and realign it after about 15 shaves

I am waiting for a new aloxite in the mail right now

I am waiting for a new aloxite in the mail right now

-

04-14-2012, 09:02 PM #10

Aloxite 200, manchester ?

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote