Results 1 to 10 of 11

-

09-24-2012, 02:48 PM #1Junior Member

- Join Date

- Sep 2012

- Posts

- 4

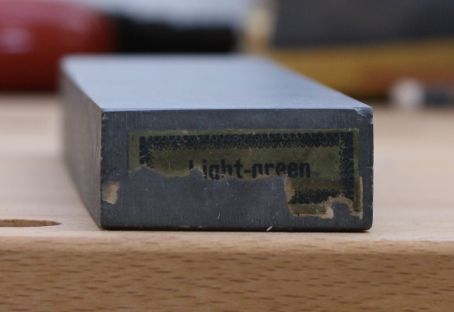

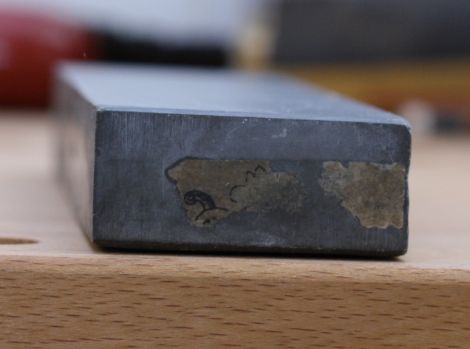

Thanked: 0 "Light Green" (Escher) hone care/maintenance (and need to find a slurry stone)

"Light Green" (Escher) hone care/maintenance (and need to find a slurry stone)

For the record, I'm a woodworker, not a stropper (shaver? shavoir? stroppetteer? how do you guys refer to yourselves?).

So I was at one of the antique tool sales that takes place a few times a year in my area (yeah... probably not going to reveal that just now, per the below...), bidding on a few things I was interested in. One of those things happened to be an old cast iron file handle (you should always put a handle on your file; those pointy file ends can really injure the palm of your hand if you're not careful and slip while filing; I've seen photos and it isn't pretty. The cast iron handle can be quickly changed out from file to file and feels vrrry nice in the palm of your hand).

Unfortunately, the lot immediately before it (a beat up old sharpening stone I never even glanced at before the bidding) didn't even get one bid, so it got thrown into mine. Ugh. I hate buying junk.

Later that night, though, I looked at it a little more closely and decided to see how it cleaned up. I ended up with this stone...

If you separate out the two, I ended up paying $375 for the stone.

Oops. Forgot the decimal point.

It was $3.75.

(Seriously, didn't know what I had until I started researching it. Here endeth the gloat.)

(And... it appears I have a piece of grit sticking somewhere in my DMT 220. That bugs me to no end...)

That bugs me to no end...)

So, anyway, it looks like I found myself a 8x2x1 Light Green Escher in the wild. Nice thickness, very minimal chipping, labels somewhat intact.

I use Norton 1k/4k stones for most of my woodworking tools. On my planes, I take the edge up to a 8K Japanese stone (nothing worth mention; it's a man-made stone from the woodworking store, came with a small nagura slurry stone); everything else is generally fine with a 4K grit edge, though. Unfortunately, several of my plane blades (namely, my 2 3/8" wide blade for my 604 1/2, my primary smoothing plane, which is the one that needs the keenest edge) are wider than 2", so I'm not sure how much use I'll get out of the stone, but that is yet to be evaluated.

I've never had such a quality stone in my shop before; not really sure of the best way to care for it. I want to make sure I either a) maintain it properly for my own use or b) don't bugger it up in case I decide to sell it. So here are my questions for the rabble:

- Best way to preserve the labels?

- Best way to flatten? (I have several DMT stones; as mentioned before, it looks like my 220 is holding some grit somewhere, so I'll have to sort that out. But also open to sandpaper and float glass or... whatever.)

- Better to sharpen with slurry or without?

- Best way to raise slurry? (Can do it easily enough with the DMT 220, but... that seems excessive)

- Best slurry stone (if raising slurry is the recommendation) and best place to get one for my new stone?

- Current market value? (more for adjusting my itemized list of shop equipment for insurance purposes, not for sale purposes)

Ummm... I think that's it for now. (But I reserve the right to ask more questions later.)

Except that I will now start paying closer attention to all of those beat up looking sharpening stones I see at auctions in the future.

Any information anyone can provide on the above questions would be most appreciated!

Cheers,

EthanLast edited by ehiker133; 09-24-2012 at 03:01 PM.

-

09-24-2012, 02:50 PM #2

You can use the DMT 325 for slurry and it will be fine.

Congratulations, nice hone.

-

The Following User Says Thank You to Disburden For This Useful Post:

ehiker133 (09-24-2012)

-

09-24-2012, 02:58 PM #3I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

you can seal the labels with clear nail polish or any other water proof lacquer.

Slurry vs no slurry is a matter of preference, but for sure not for tools, IMO a huge waste of hone if not used on razors.

Slurry can be made ith diamond palte, but most people use small thuringian slurry stones , many Eschers come with their own slurry stones.

We do not do valuations, you can look them up on e-bay to get an idea of price range.Stefan

-

The Following User Says Thank You to mainaman For This Useful Post:

ehiker133 (09-24-2012)

-

09-24-2012, 03:09 PM #4Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

You lucky thing! Lovely stone.

It is realtively soft, so you could use the (wet-and-dry) sandpaper and float glass method of lapping to by-pass the scratchy 220 plate.

As you will be using it as a final polisher, you most likely will not need to raise a slurry - most of the thuringians raise what they call 'a thin slime' as you hone on them, and that is usually enough. It will probably be the equivalent in finish to 12k or 12k+ hone, so your 8k would come before it in progression.

Regards,

Neil

-

The Following User Says Thank You to Neil Miller For This Useful Post:

ehiker133 (09-24-2012)

-

09-24-2012, 03:27 PM #5Junior Member

- Join Date

- Sep 2012

- Posts

- 4

Thanked: 0

Thanks for the additional info! I'll give that a whirl the next time I'm working on a plane blade and see what happens.

As you said, it's just a final polisher, so I'm thinking I'll try to figure out a way of using the stone with my larger smoothing plane blade, anyway. (freehand?... ugh. But not impossible with a hollow grind.)

Cheers!

-

09-24-2012, 03:40 PM #6Senior Member

- Join Date

- Jan 2009

- Location

- Michigan

- Posts

- 178

Thanked: 45

Very nice stone. I recommend that you don't use the Escher for your plane blades, it's unnecessary and better suited for razors. Your 8k stone is more than enough for woodworking.

-

The Following User Says Thank You to mattluthier For This Useful Post:

ehiker133 (09-24-2012)

-

09-24-2012, 03:49 PM #7Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

It will be a waste of time to use it on woodworking tools, especially if you're using something with modern steel (chrome vanadium or A2) that's not 01 steel.

It's too soft, and worth a lot more kept to work a razor or sold to someone who is going to use it to work a razor.

If you want a notch-up edge on any of your woodworking tools, let your polish stone dry and burnish the edge as it loads, or cut a piece of MDF 8x3 and use any one of the various buffing sticks or pastes that contain chromium oxide. They will cut faster and leave an edge more keen.

I came into this disease through woodworking also. I'd have to say now that I like shaving with a straight razor at least as much as working wood.

-

The Following User Says Thank You to DaveW For This Useful Post:

ehiker133 (09-24-2012)

-

09-24-2012, 04:17 PM #8Junior Member

- Join Date

- Sep 2012

- Posts

- 4

Thanked: 0

Very true, Dave. And, honestly, that's the reason why I've never bought a stone (or even considered one) over 8K.

Most of my plane blades are LV A2 or Hock A2 replacement blades, so there is a lot of value in your statement.

Just seems... sad... to let go of something so nice.

Please, don't get me into straight razor shaving. I'm sure I'm a perfect candidate, per I absolutely loath shaving, and it's mostly because I despise paying so much for razor blades that I wear out after two or three uses. With woodworking and wearing kilts and scuba diving, I need another expensive hobby like I need a hole in my head.

I'll ponder your words. Maybe I'll end up with a post over in the For Sale section...

Cheers,

Ethan

-

09-24-2012, 04:28 PM #9Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Well, you can always hold on to it and buy a razor...something with a price tag of about $20. You can always sell it later.

There's no great need to buy expensive razors to get a great shave. As long as they have a lot of life left and are straight, you have the gear to take a $15 razor with some cosmetic issues and with the addition of about $20 of horse butt strips turn it into something that literally could shave you for 3 decades.

I love the natural razor stones, but I always fall back on two shaptons and a bench for woodworking. I think you should give the shaving a whirl, though. It doesn't even need to take long or be a semi-religious experience. It takes me, with stropping, less than 5 minutes to make two passes each morning. I never gnash my teeth now about whether or not I can get another shave or 10 out of a marginal cartridge.

You have in your possession now about the most foolproof finisher you could find for razors with simpler steels.

-

09-24-2012, 04:41 PM #10Junior Member

- Join Date

- Sep 2012

- Posts

- 4

Thanked: 0

Nooooooooo!

Da** you, Dave...

Still... might be worth a try. I DO have the most expensive bit out of the way, now, don't I? What's the worst that could happen? Aside from slicing my nose off, that is... My wife might even like the idea of me spending less on those danged cartridges.

Hey, do people make custom wooden handles for straight razors? I...

Grrr... Thanks, Dave. Already taking it too far.

*sigh*

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote