Results 1 to 10 of 14

-

04-27-2013, 03:35 PM #1

Some more hones purchased from france

Some more hones purchased from france

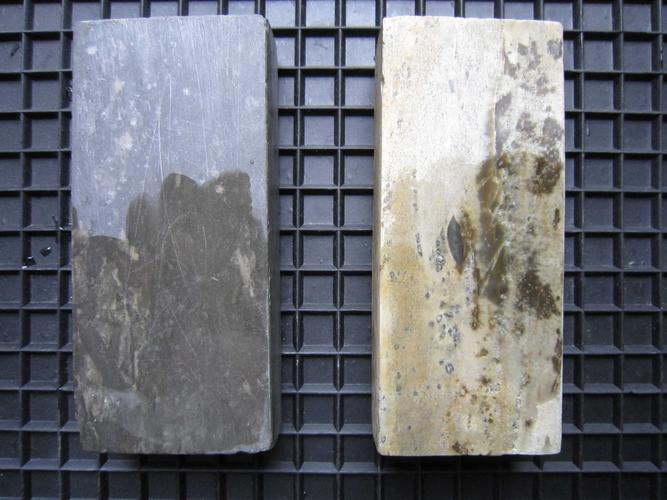

I recently bought two hones on the french bay. They come with an old well used Thiers Issard razor and from the pictures I thought both of the stones could be turkey oilstones.

Having the stones in hand now, I am not really shure what they are.

One is white, marble like and very hard and could be a novaculite. This stone has also been used with oil in the past. The second one is somehow blue green in color. It has some white stains that reminded me on the turkey oilstones at the first look, but it is very different to the turkeys I have. Also I don't think it is novaculite - if so - than a very pure one. The stone is very soft and fine - looks and feels more like a slate, somehow comparable to a thuri. Also the look through a loupe shows the typical slate surface.

The stone has not been used with oil before.

Any ideas?

-

04-27-2013, 04:27 PM #2Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

They look like the new-ish 'turkey' stones to me - Vasilis knows a lot about these. Mine can be used to cover a number of grades - the slurry (produced with a DMT) breaks down to become finer and finer. You can go from bevel creation to pre-finisher with some of them. The older ones were finer, in my opinion.

Regards,

Neil

-

-

04-27-2013, 04:28 PM #3

The white one could be a Cretan Hone, a very good natural bevel setter (if used with heavy slurry), the other one seems a Turkish oilstone, which is the same stone as Cretan,but baked with oil for hours in a oven, Cretan is rough and Turkish is baked, but if you say that is literally a different stone, I don't know.

Last edited by Bushdoctor; 04-27-2013 at 04:30 PM.

-

The Following User Says Thank You to Bushdoctor For This Useful Post:

hatzicho (04-27-2013)

-

04-27-2013, 05:14 PM #4

The blue one I think has never seen oil. It is not that typicall - baken in oil - stone I know from the turkeys. Its really different. Try to make some pictures in comparison to the turkey stones I have tomorrow with daylight!

-

04-27-2013, 09:11 PM #5

Both of them look like "Turkish oilstones". Try to dip the white one in oil, and it will get black. The second, dark one, it could also be a Turkish oilstone. The thing about them (at least, this specific type of novaculite stones) is, when used with plain water, they feel like harder stones, and without the greatest feedback. But if you turn them into oilstones, they feel softer and finer. You don't have to do so. Each type, the water stone and oilstone, has its different interesting characteristics.

And, there are indeed many, many different grades of them.

A few months ago, I shipped one, finisher grade, to a friend in US, that found it as good as his yellow green Escher. And, you also have the ones used for bevel setting with slurry, that also do a great job at this. You can cover the whole bevel setting to finishing of a razor or knife or anything, using 3 different grades of stones from the same mine.

I would be interested in seeing those two after a good lapping.

Also, they don't have to look like the dull dark blue with the white spots and lines like cracks on glass, giving it a false semi-transparent-ish appearance. There are variations on how they look too.

-

-

04-28-2013, 02:00 PM #6

Thanks a lot Vasilis for the info.

So far I only knew the typical turkey oilstones, black color from the oil they have been used with, white spots and calcine veins.

I took some pictures of the darker stone in comparrison to my other turkeys to show the difference, but the more I look on the photos and compare it in reality to the other stones, I think it might be really a turkey stone.

I will be curios how they perform in honing!

-

04-28-2013, 03:30 PM #7Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Vasili

What do you recommend for lapping?

I have several, I suspect are Turkish or are at least Novaculites. Typically I use 100-120 drywall screen on cement floor to flatten, then loose Silicone Carbide on Granite and finish on wet & dry to 1K.

-

04-29-2013, 10:05 AM #8

I usually prefer dry sandpaper on a flat surface. Whenever I use wet sandpaper or diamond plates, it takes ages to do what some dry sandpaper does in 10'. You can try it yourself and tell me what you think. The loose powder sounds good too. For the diamond plates, they get clogged up if used dry, and are slow if used whet, so I use them only for light conditioning or finishing.

-

-

05-03-2013, 10:36 AM #9

They look like Turkish stones to me!

Keep us posted.

-

05-04-2013, 08:27 PM #10

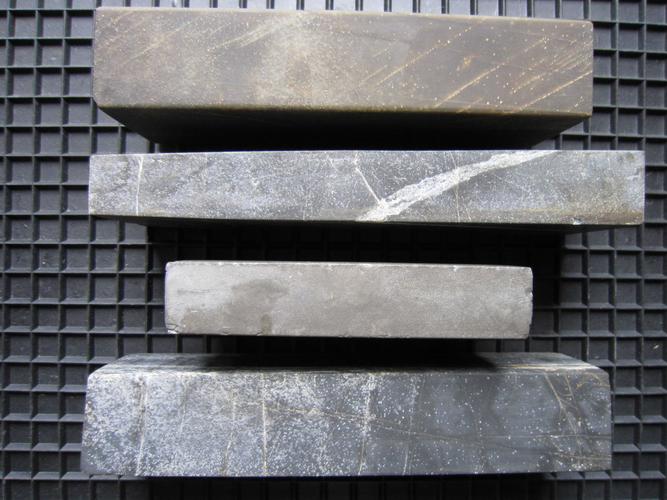

Nice Turkish stones hatzicho, thanks for sharing. Here’s a couple more pics..

Not a Turkish stone, do you know this one hatzicho?

16Likes

16Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote