Results 1 to 5 of 5

Thread: Lapping Vosgienne

-

05-10-2013, 03:42 AM #1Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215 Lapping Vosgienne

Lapping Vosgienne

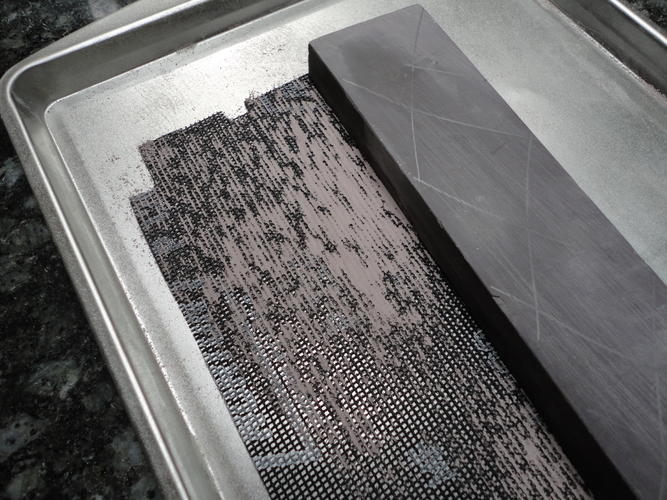

I recently acquired a Vosgienne hone in a plain wooden box, badly in need of lapping.Typically I flatten Natural stones with lose 80 grit Silicone Carbide, but I have had good success with this new method, using 100-120 grit Silicone Carbide Dry Wall sanding screen, dry.

Loose Silicone Carbide works great and quickly, relatively. I can get a Novaculite flat in about 20-30 mins, but it is messy.

Now I use the dry wall screen in a cookie sheet on a granite slab. I lap on top of my Air-conditioning evaporator, the height allows me to use my body weight. A flat piece of cement (garage floor) works as well but is hard on the knees and back.

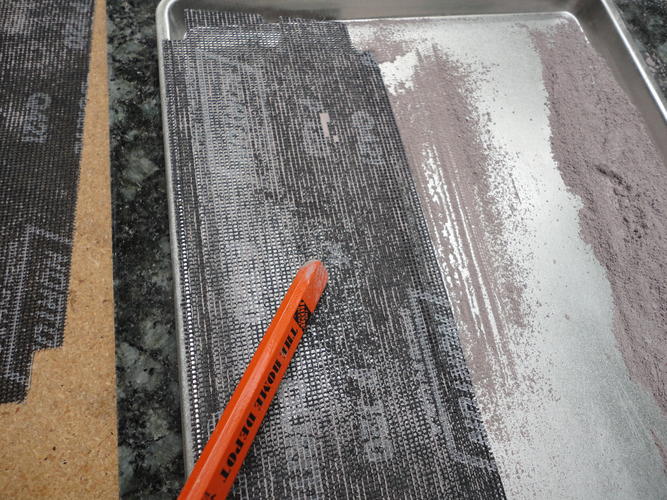

The key is, to use the paper and screen dry and finish wet, a tip by Vasilis on another thread. It works well and fast. I started lapping this stone on the screen, dry and as I dumped the Vosigne dust into my planters, I recalled a recent thread about saving lapping dust. I decided to collect the dust and see how much could be saved.

You will need a cookie sheet, larger is better, a soft lead pencil, a hard flat surface, cement or granite slab, larger the better a 3x5 index card and 100-120 grit drywall screen, 220, 320, 400, 600 an 1K wet & dry.

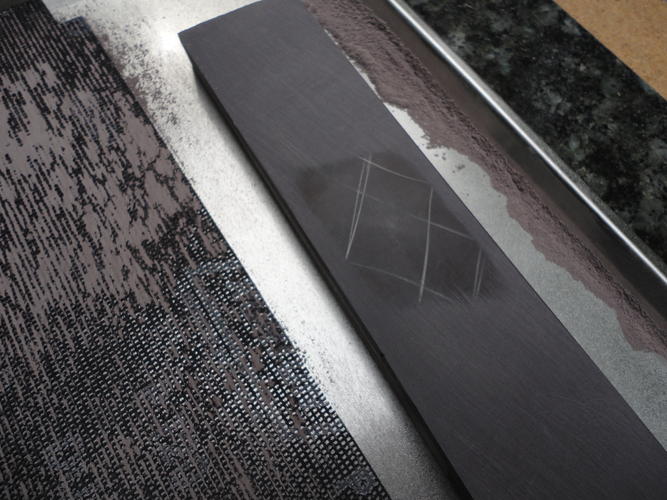

Mark a grid on the stone with a soft pencil. The dry wall screen will load up with dust and become ineffective, standing on edge and tapping with the pencil knocks the dust to the sheet.

Use the 3X5 card to squgee the dust to one side. Keep rotating the screen & stone180 degrees to use every inch of screen and keep the stone flat. In about 20 mins and 2 screens the stone was flat and new grid marks came off easily in 5-10 laps. I do light finishing laps at 45 degrees to remove scratches.

Collect the dust as needed with the 3X5 card and save in a container. I collected about 2 ounces of dust, not counting what I threw away, about a half ounce.

Once all heavy marks are removed, lay down a piece of 220 W/D, dry. Work your way across the paper on one end, dry then spin and use the other end. By the time the paper is fully loaded up, most of the scratches will have been removed. Rinse the paper with water, I used a spray bottle, lay the wet paper back on the cookie sheet and lap with a mist of water, until all the marks are removed. Do the same all the way up to 1k wet & dry, dry first then wet. The progression goes quickly after 220. The wet & dry can be saved for the nex tlapping session.

Start to finish was about 45 mins. The stone came out like glass and produces an edge much smoother than an Escher. I collected about 2 oz. of dust, don’t know what I will do with it yet, I do believe it is well contaminated with Silicone Carbide.

I was surprised by how much dust was collected.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

stimpy52 (05-10-2013)

-

05-10-2013, 08:35 AM #2

Oldengaerde told me about using sanding meshes for lapping years ago and I have been using it since. I use it wet on a glass plate. It works great for initial lapping and leaves a near flat surface. It's especially useful for dished novoculites. The meshes last very long, you can use it for multiple stones before they're worn out.

Unless you want to bake Vosgienne flavoured cookies throw away the slurrie dust.

-

05-10-2013, 12:58 PM #3

-

05-10-2013, 04:06 PM #4Senior Member

- Join Date

- Mar 2009

- Posts

- 1,211

Thanked: 202

I have to say that it is interesting method but there are much faster methods especially for hard stones. One which I use is is to have a good quality linisher belt glued onto a worktop slab. I start on 40 grit if I need to remove a lot of dishing for example 4-5mm on CF can take about 10-15 minutes and also I start dry until it is flat. Cleaning it with a brush. Respirator is a must. Then follow on finer grit belts again dry followed by W/D papers wet to finish lapping. Through the years I have accumulated quite a bit of dust from grinding different hones but is is all contaminated. It could be cleaned and used for another purpose by diluting it with a liquid, spinning it a leaving it to settle which should roughly separate different grits. However I think it is not worth the effort for quality and purity of resulting product. I have intention to use your method for softer hones.

-

05-12-2013, 01:18 AM #5

Congratulations, nice stone. Thank you for sharing.

Mike

5Likes

5Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote