Results 1 to 6 of 6

-

09-24-2013, 06:07 PM #1

Should I buy 1 or .5 micron Diamond Spray?

Should I buy 1 or .5 micron Diamond Spray?

I use films to hone. I have a film that is from Tools for Working Wood that is labeled 1 micron but they say it is around 8000 grit. I have Chromium Oxide from Kremer Pigments that is rated .3 micron. I'm buying a Diamond Spray for finishing. Should I get .5 or 1 micron. Chromium oxide is usually around .5 micron so would .5 Diamond be repetitive?

-

09-24-2013, 06:53 PM #2

I don't have any experience with Diamond sprays other then what I've read. They work well but because they are pointy sharp (think of a diamond), they do put a wicked edge on if it's already worked up through the progressions, but it's a bit harsh to some.

I've been using crox for a little while and it puts a nice edge on a shave ready blade but leaves it smooth for me. The crox compound is rounder in shape and leaves the steel smoother.

At least that's my take on it.

-

09-24-2013, 07:02 PM #3

I've read that too. I'm just torn between the two sizes. Will Chrox be able to smooth out the edge made by the 1 micron?

-

09-24-2013, 07:51 PM #4member emeritus

- Join Date

- Dec 2012

- Posts

- 112

Thanked: 62

Do you use chromium oxide after the one micron lapping paper? On what substrate?

What do you want to change about that edge?

I have experimented quite a bit with diamond and boron nitride sprays on leather strops.

I have given up on 0.5 micron diamond spray, I find it just convexes the bevel without adding much keenness.

I would suggest 0.25 micron diamond spray after the 1 micron lapping paper.

-

09-24-2013, 07:56 PM #5

"What do you want to change about that edge?"

I do use Chromium Oxide after the film. My edges feel smooth but not as sharp as I would like. I was hoping that using diamond would make the edge sharper before smoothing it our with the Chrox. Am I thinking of this the wrong way?

-

09-24-2013, 08:39 PM #6member emeritus

- Join Date

- Dec 2012

- Posts

- 112

Thanked: 62

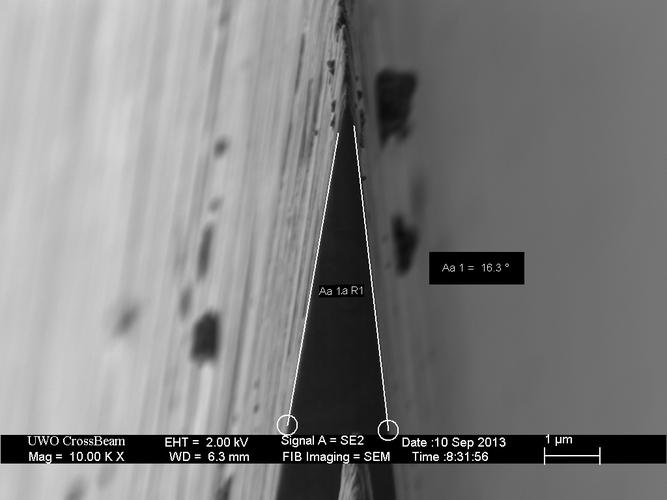

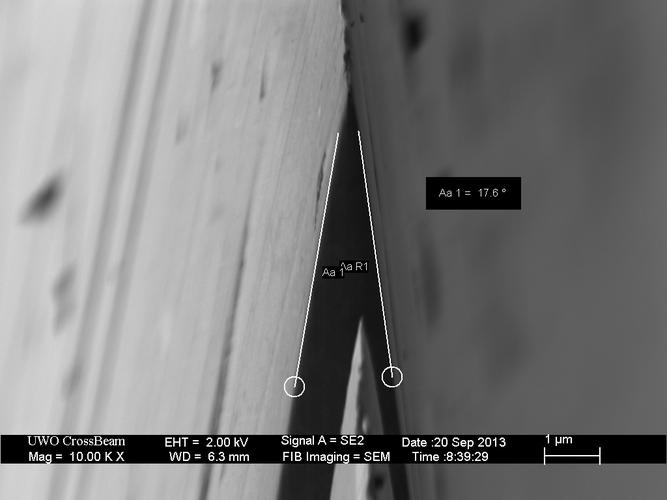

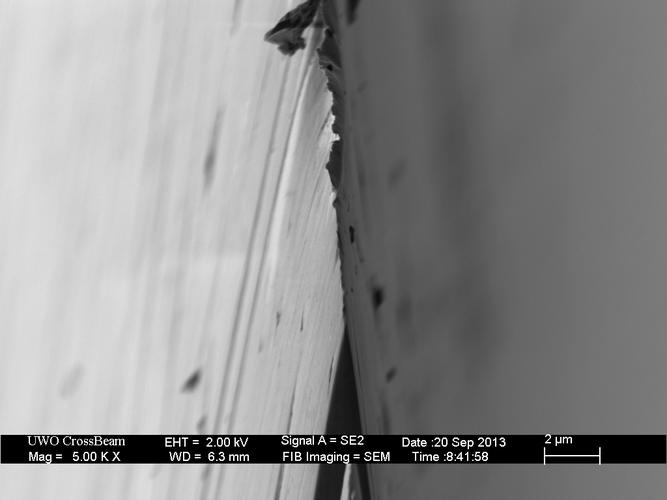

If you want to add a bit of "sharp" to the edge, 0.25 micron diamond is a good choice. This will introduce a bit of micro-convexity near the apex, but not convex the bevel as would 0.5 micron or larger.

I posted some images in this thread:

http://straightrazorpalace.com/advan...spray-sem.html

Here is another example:

After the Gokumyo 20k, no convexity.

Following 10 laps on each of 0.25 diamond and 0.10 boron nitride, slight micro-convexity.

Slight foil/burr that can be stropped away.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote