Results 1 to 8 of 8

Thread: Raising a burr???

-

12-18-2013, 04:06 PM #1Member

- Join Date

- Dec 2013

- Posts

- 68

Thanked: 23 Raising a burr???

Raising a burr???

Is there a consensus on the practice of raising a burr during edge setting? Do you do it or not?

-

12-18-2013, 04:10 PM #2Member

- Join Date

- Dec 2013

- Posts

- 68

Thanked: 23

I thought I was in the honing thread, can this be moved?

-

12-18-2013, 04:19 PM #3aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Burrs are something that knife guys do, for us it's staying on one side too long and no backstroke.

Burrs + Straight Razors = Bad (we start honing razors where we quit on knives)

Burrs + Knives = Good (a little tooth on knives is good for cutting action)Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

12-18-2013, 04:39 PM #4

+1 for the above.

On knives, it means the blade is ready for the next stone. It can be used as a sign that the edge is ready.

On razors, it means you've gone too far and removed too much metal. You can have both your edge just as sharp as needs to be, and without any burr, if you follow the basic tests Sharpness tests explained - Straight Razor Place Wiki

-

12-18-2013, 04:51 PM #5

A burr on the edge shows that you've gotten completely to the edge. Knives can feel sharp--before this happens, so always make a burr on your knife edge to ensure a complete bevel. (as the Japanese do)

A burr on a razor is a wire edge, to be avoided, but easily fixed. Magnification really helps-and proper touch.

-

12-19-2013, 05:32 PM #6member emeritus

- Join Date

- Dec 2012

- Posts

- 112

Thanked: 62

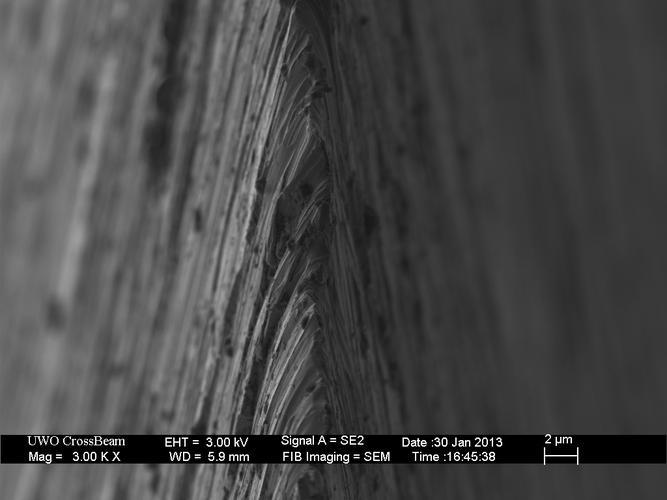

Here is an edge after normal x-strokes on a DMT1200:

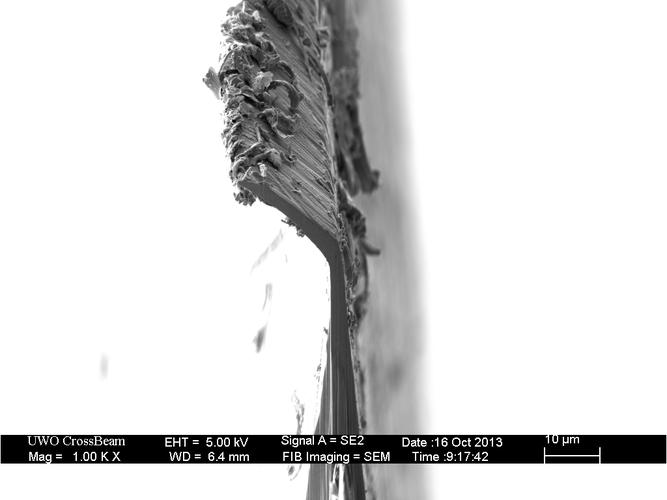

Here is a cross-sectioned view the same blade after 100 half-strokes (repeated x-strokes on the same side):

The Burr (or wire edge) is formed during repeated half-strokes because the edge bends away from the hone and continues to grow (this one is nearly 30 microns long and could be felt with my finger). The problem with this burr is that is is 3 or 4 microns thick but we are looking for 0.1 micron edge width for shaving (one tenth of a micron). Normal x-strokes on a DMT1200 easily brings the edge width below one micron.

The burr is easily removed with a few normal x-strokes.

A lot of steel wasted for no purpose in my opinion.

-

The Following 3 Users Say Thank You to fuzzychops For This Useful Post:

Double0757 (12-20-2013), ScottGoodman (12-20-2013), Vasilis (12-19-2013)

-

12-19-2013, 05:52 PM #7I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

Burrs on knives are good thing.

On razor burrs are bad thing, the razor blade is very thin and it will wear out in no time if burrs were involved. With proper technique and care a razor should last at least one generation.Stefan

-

12-19-2013, 07:20 PM #8Member

- Join Date

- Dec 2013

- Posts

- 68

Thanked: 23

10Likes

10Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote