Results 1 to 9 of 9

6Likes

6Likes

Thread: Razor Repair Help

-

01-18-2014, 09:01 PM #1Junior Member

- Join Date

- Jan 2014

- Location

- Fredericksburg Virginia

- Posts

- 3

Thanked: 0 Razor Repair Help

Razor Repair Help

Hello all.

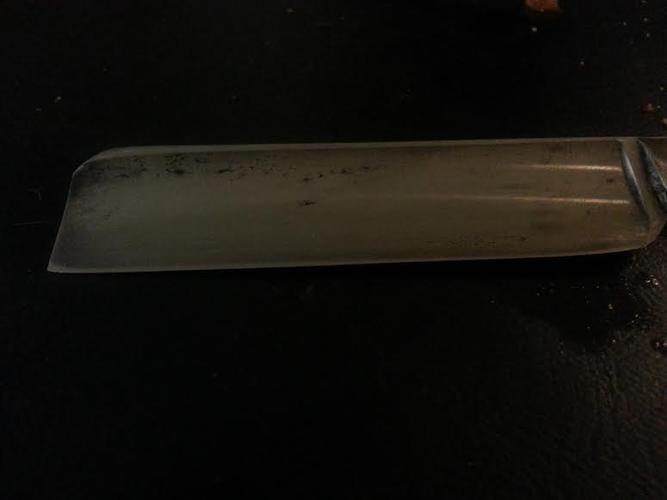

I couldn't figure out where to put this one, so I guess honing is the closest. My fiancee just purchased me a "new razor" (new to me, but in reality an antique.) It's a dubl duck special no.1 and from what I can tell a rather good blade, however, because it was made in the 1940's, and it looks like it might have actually seen combat in WWII (hyperbole, but you never know,) the metal is rather pitted and worn. The edge itself is ok, but there is some pitting in the hollow.

I make my own knives, so I'm a decent hand at metal repair and a little too proud to have someone else do it for me. I attempted to repair the damage myself but after six band aids and two hospital visits, I think I might need to break down and see if anyone here has any ideas on how to repair this blade. It's a beautiful blade and it would be a real shame for it to be relegated to a shelf. Also, I usually use a whetstone and elbow grease to repair blades, but from what I've read here, that is a bad idea. The honing stones I have are slightly too big to reach into the hollow, and I really down want to have to use my dremel, but I'm at my wits end.

Any Ideas?People say that inside of every fat person, is a skinny person trying to get out. I say that outside of every skinny person, is a fat person trying to get in.

-

01-18-2014, 09:04 PM #2

Yep, post a pic. Without it, we'll just be guessing!

I do have an educated guess that says you haven't found this thread yet: http://straightrazorpalace.com/works...wers-here.html.I want a lather whip

-

01-18-2014, 09:09 PM #3Senior Member

- Join Date

- Oct 2011

- Location

- Moses Lake Wa.

- Posts

- 162

Thanked: 20

Sand paper and a piece of doweling works for me when I want one really polished. A small strip of Electrical tape acrossed the edge to keep it from nicking me also helps. I have taken a few of mine up to 5000 grit sand paper to remove all the scratches. I have also used shaped Pencil/art erasers for following the shape. If the pitting isn't to bad and you don't mind it... skip all the work and just polish it up with some metal polish.

-

01-18-2014, 09:14 PM #4Junior Member

- Join Date

- Jan 2014

- Location

- Fredericksburg Virginia

- Posts

- 3

Thanked: 0

Yeah, looks like I missed that one. Thanks Laurens. Sorry about the picture quality, but that damned flash was not working with me.

People say that inside of every fat person, is a skinny person trying to get out. I say that outside of every skinny person, is a fat person trying to get in.

People say that inside of every fat person, is a skinny person trying to get out. I say that outside of every skinny person, is a fat person trying to get in.

-

01-18-2014, 09:20 PM #5

Thanks for the pic

It doesn't look so bad to me, I would think metal polish on a cloth or steel wool (never tried the latter myself, but have heard of good results from others) should clean up most of the spots.

It doesn't look so bad to me, I would think metal polish on a cloth or steel wool (never tried the latter myself, but have heard of good results from others) should clean up most of the spots.

You've got one very pretty razor and I'd rather have you send it out to a pro or keep it the way it is than ruin it (and your hands, for that matter) by trying to treat it like a knife. Don't use a Dubl Duck for restoration practice, you'll regret it! Just my opinion of course, but I think you should keep it like this, get it honed (check the Classifieds -> Member services) and enjoy good shaves I want a lather whip

I want a lather whip

-

01-18-2014, 09:26 PM #6Junior Member

- Join Date

- Jan 2014

- Location

- Fredericksburg Virginia

- Posts

- 3

Thanked: 0

Thanks bud. Yeah I think I'm going to have to break down and have someone else take care of my blade for me (for the first time ever.) I don't think my finances can handle another visit for stitchings. Appreciate the help.

People say that inside of every fat person, is a skinny person trying to get out. I say that outside of every skinny person, is a fat person trying to get in.

-

01-18-2014, 09:28 PM #7

Good choice

You could always take pictures of your stitches and locate the Cut of the Day thread

You could always take pictures of your stitches and locate the Cut of the Day thread  I want a lather whip

I want a lather whip

-

01-18-2014, 11:55 PM #8Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,444

Thanked: 4828

I use old wine corks to help give me something to grip and keep my fingers clear. 10pups has a thread about the sanding tools he uses http://straightrazorpalace.com/works...es-reaper.html souschefdude has some threads as well that have some nifty tricks as well.

It's not what you know, it's who you take fishing!

-

01-19-2014, 01:03 AM #9

Thanks for the referral Rez.

As Rez does I also use corks. I have created a drum sander from a cork too, besides hand sanding. If you are new to this I recommend hand sanding. Stay away from the Dremel for now.

That blade looks i decent shape. Cut a piece of SP 2" by 3 1/2 ". This will wrap around the cork and leave a little overlap for grip. Keep the blade edge flat on a workbench and you should be able to avoid any more stitches. The look of that blade appears to be at least 1000 grit to start, wet/dry sandpaper. Then 1500, 2000, 3000. At that point a shot of mothers polish with a rag and you should have a nice shiny piece of steel to send out to be honed. If after the 1000 you still see pitting and feel the need to remove it, go down to 800, then 600 if needed. Below that you are going to leave waves in your metal that look as bad as the pits. Even 800 can be harsh.

Good luck, and ask questions....

Oh, and pictures, we love pictures...

We love Ducks too, at least I do, I have 6.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote