Results 11 to 20 of 21

Thread: TI Le Dandy honing headache

-

02-20-2014, 05:19 AM #11Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

If you make a sleeve the edge will come togeather, I have used clear plastic hose. Yesterday at Home Depot I saw some hard white plastic line for refrigerator Ice Maker hook up and though that would work well for a razor sleeve.

The bevel will be thin or perhaps a double bevel but they will come togeather and shave.

I have several old TI’s and they are some of my favorite shavers. They don’t have to be perfect to be good shavers.

Make it shave.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

MikeB52 (02-22-2014)

-

02-21-2014, 10:08 PM #12

To add to what Euclid440 has said you should be able to use some basic math to work out how wide the spine needs to be to set an angle.

If you know trigonometry this will help.

If you don't there are numerous calculators online to work out right angled triangles.

If you go this route you have to remember some basic rules in converting to a razor from right angled triangles.

First to make a razor into a RAT you have to theoretically split the razor in half. So you use a single RAT per razor side.

You already have the blade depth, but working in inches requires decimalised inches. This is harder than working in metric.

The basic route would be to measure the blade spine to edge. So if your razor is a perfect 5/8 then your metric value is 15.8mm.

You already know the angle you want for the bevel 18 degrees. You have to half this as you are splitting the blade into 2 triangles. So 18 becomes 9 degrees.

Here is a RAT calculator.

Right-Angled Triangle Calculator

Your Side b is 15.8

Your Angle A is 9

Therefore Side a (the spine) needs to be 2.5mm per triangle. Your using 2 triangles so the total spine width should be 5mm.

Now you know what sort of ball park figure the spine should be at to get a good angle you can test various materials to try build the spine using spine clips, tube, or sleeves to get into the correct bevel setting region.

The math also works backwards. So if you build the spine to 5.5mm you can plug that back into the calculator.

Spine = 5.5mm so, edge a = 2.75mm

blade width = 5/8 = 15.8mm

Therefore Angle A = 9.87 Multiplied by 2 for each razor side = 19.74 degrees.

A bigger angle = less bevel.

I think most razors are 17-22 degrees total bevel angle. 22 will be a smaller bevel than 17, I would aim for 18-19 degrees to be on the safe side.

The smaller the razor the more pronounced a change in spine width will change the bevel.

A 3/8 razor will change it's bevel angle with far less spine wear than an 8/8 razor will.Last edited by Iceni; 02-21-2014 at 10:16 PM.

-

The Following User Says Thank You to Iceni For This Useful Post:

MikeB52 (02-22-2014)

-

02-21-2014, 10:32 PM #13

Hi MikeB52 - I have a TI frameback #69 and a #19, both were honed by Valery, and each time he's honed them he's mentioned that the steel is particularity hard on these blades, and it took some considerable work to get a nice edge on them, and he's honed thousands of blades.

I'm sorry I can't comment on the actual honing procedure, but I know if Valery said they are "difficult" blades to hone, you're not alone in having some trouble.

Cheers!

-

The Following User Says Thank You to Phrank For This Useful Post:

MikeB52 (02-22-2014)

-

02-22-2014, 12:17 AM #14

Yes to what shooter said.

A look at your picture I see a fine old well worn blade.

My guess it has a bevel shape that matches the hone of the

previous owner.

Use the magic marker trick to see if your hone strokes

are touching the edge as you expect.

After trying this with tape try it without tape.

A magic marker test without tape should let you see

a thin as a whisker ink line and even bright steel

on the bevel.

Hard steel (yes ... TIs) combined with a fine hollow grind do flex

and distort the way the hone attacks the bevel. This in

turn makes hone progression difficult.

Use a magic marker that is easy for you to see and use a bright light.

Red and green markers work better for me than black....

I also use a 10x glass from time to time.

Looking at the wear in the photo I would start with circles

and a light touch. Circles seem to rock and give me an

even hone on worn razors. Well enough that I do not need

to "fix" a smile or other problem.

-

02-22-2014, 12:31 AM #15Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,463

- Blog Entries

- 1

Thanked: 4207

Great, helpful replies gentlemen, thanks for the tips.

I can still spell trig, but haven't used it since performing weight and balance calculations for aircraft during yearly inspections.

Visualizing two triangles, and the resulting bevel line is actually a pretty cool way to look at it..

I was half considering taking the blade into work and strapping it to our metal milling machine and removing the spinal irregularities with a low speed fly cutter but have decided to try to level up the heel and spine some with a 325 and 600 grit stone instead, chickened out on the mill. Although, if I find another nice TI I can afford, may get new confidence to try more extreme techniques. Wonder if anyone has actually tried to use a mill to work on razors..

I read a neat idea Gssixgun posted about building a false true-ish spine with some electrical tape, grinding it down, then adding new layers of fresh tape over that. This also sounded like a great work around to a buggered spine so really I guess it's only for esthetic reasons I am trying to fix the actual spine now. That and some experience restoring sharp metal tools, of course..;-)

Will post some 'after' pics when I get the shape in better , well shape..

Cheers.

-

02-22-2014, 08:46 PM #16

I am glad you backed off this idea.

I wrecked a couple eBay dogs attempting to true them up.

My current opinion is that a well lapped flat hone set will

eventually get a razor right. All I have to do is watch it with

the magic marker test and give it some hone laps to true it

up and then circles and X strokes to hone it for shaving.

After six months or so of maintenance it will come home.

My best shavers have smiles.

Tape helps a lot of things.... one or two layers....

What works is the right answer.

-

02-22-2014, 10:26 PM #17Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,463

- Blog Entries

- 1

Thanked: 4207

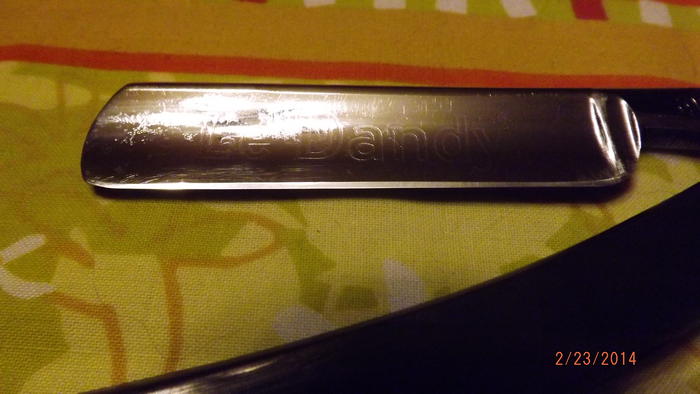

Results after taking the heel down some more and working the spine slowly on both sides on the stones as pictured. Tough to really get a clear spine shot.

Bevel seems straighter along the blades length, narrower at heel than toe after honing with two layers of tape, which I expected with the 1/16th greater toe width than heel. Marker test showed even line.

Haven't stropped or tested yet but will advise.

-

02-23-2014, 04:31 AM #1850 year str. shaver

- Join Date

- Aug 2008

- Location

- Pothole County, PA

- Posts

- 2,258

- Blog Entries

- 2

Thanked: 522

Nice contour on the heel. Looks good from here.

JERRY

OOOPS! Pass the styptic please.

-

02-23-2014, 06:01 AM #19

Recently I was honing a stainless. F stainless by the way. I was on the 3k. I was checking the edge on arm hair. Every time I did circles it lost the edge.

Why? I got no clue. Point is some razors are just funky. Keep tweaking and playing. Some hate pressure. Some want to be dug deep into the rock and ridden rough. Some razors like rap music.http://ashevillewetshavers.weebly.com/ April 26-27th come to one of the greatest meet ups of wet shavers!

-

02-24-2014, 05:22 AM #20Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,463

- Blog Entries

- 1

Thanked: 4207

Well I tried this French blade out again tonight after taking her to the stones once more. Put more efforts into the strokes than before and used a good slurry on the 4k before doing a pyramid on the 4/8, than moving up to the 12k cnat with clear water but again, more down force than in my previous go's.

Anyway, might have been treating her like more of a lady than she wanted all along. That and the spine smoothing, 2 layers of tape and 100 strokes on a bridal leather strop at the end of it all gave me a good shave. Not a great shave, but a good one.

I also tried a little rap music, just in case.

Blondie - Rapture - YouTube

Cheers all, have a good week.

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote