Results 11 to 20 of 20

Thread: Chromium oxide ?????

Threaded View

-

05-15-2014, 12:02 AM #1

Chromium oxide ?????

Chromium oxide ?????

Hi everyone

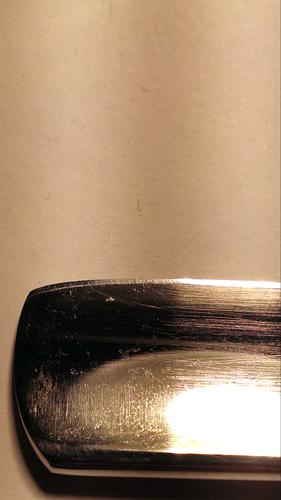

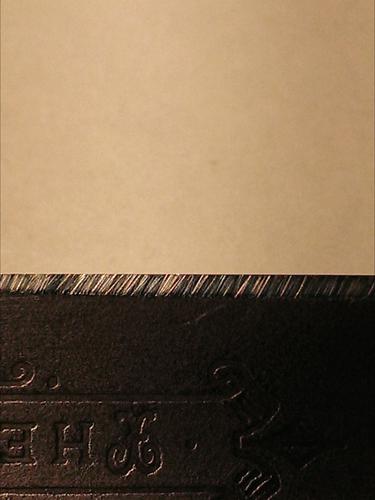

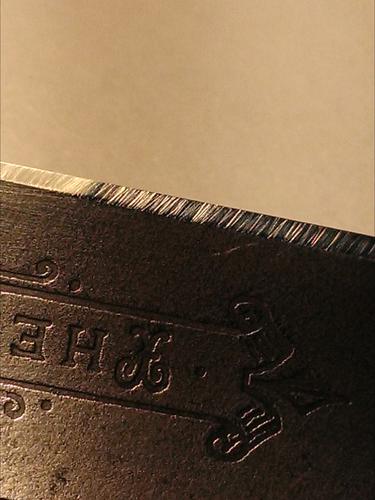

I've always have been shaving straight of the hones (purple welsh slate) but recently I have ordered some chromium oxide for the first time, so I've applied it to a piece of leather I had left over after making strop. After about 20 passes I realised the chromium oxide really scratches my bevel, I have taken couple if pictures to show you guys what I mean bare in mind those are just close up made with smartphone (htc 8x)

Pictures show 2 razor I stropped on this CrOx one on leather and one on just plain printing paper. Edge looks much more scratched then after my purple hone but it shaves ok, my question is are those scratches from 1K maybe or is the CrOx I bought unusable? My honing progression is 1k/6k combo ice bear from King then Dragons Tongue and finish on the Purple with and lather. Just to let everyone know I bought this CrOx from merchantUK/taylors1000 seller on ebay.

20g Chromium Oxide Straight Razor strop Dressing CrO | eBay

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote