Results 1 to 10 of 20

Thread: Chromium oxide ?????

Hybrid View

-

05-15-2014, 04:20 AM #1

I like the use of light at that angle in your photos. They accentuate the stria and don't hide the defects.

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

05-15-2014, 03:28 PM #2

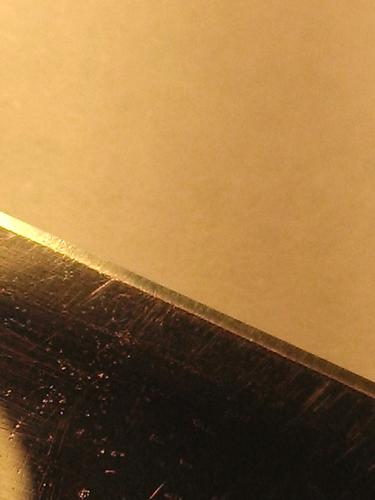

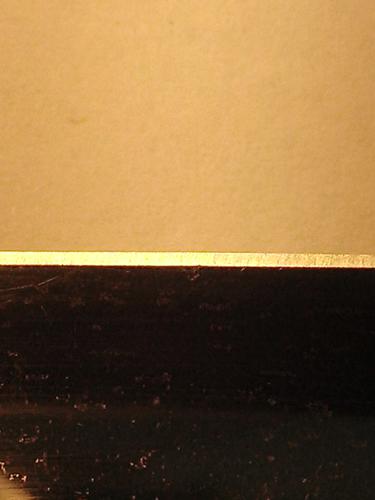

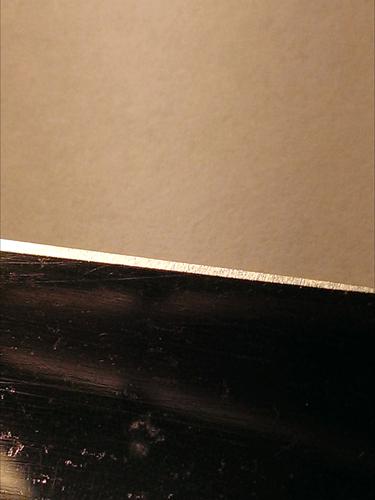

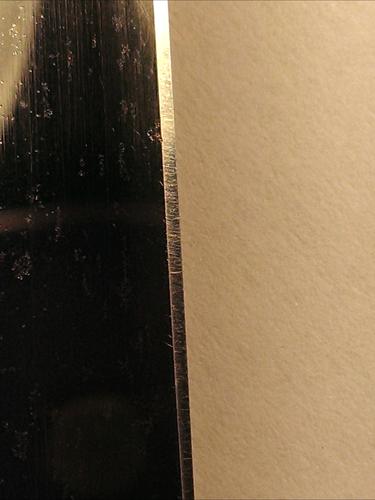

normal honing progresion

normal honing progresion

ok as promised I've honed one of the razors (the one which pictures are on top in original post) with my normal progression tried to replicate the conditions for picture

1000 grit king ice bear

6000 grit ice bear (should have spent little more time on that one perhaps)

Dragons Tongue (in picture the scratch pattern looks worse than 6k but believe me this is only because the bevel from DT is not as shiny helps ta capture the scratches)

Last picture the Purple hone LLYN MELYNLLYN I found it is called, usually I just shave of this bevel and shave is smooth and forgiving, actually taking the picture shows some scratches maybe from 1k than I never see with naked eye, ill take her back to 6k tomorrow

Now I have taken the other razor and stropped it on the "CrOx" but this time I stropped from toe to hill instead of hill to toe movement, what I can see is crosshatch pattern, this tells me the CrOx is not pure, the scratches are definitely from it as I never ever ever hone toe to hill.

Hope this warns people as not to buy this CrOx as the strop dressing like I did, at least I have some polishing compound.

Now the question is where can I get the pure stuff, I know Tony Miller from strop shop UK sells some stuff, is it the pure stuff though?

Any father advice on honing would be helpful too. Regards Rafal

-

The Following User Says Thank You to RafalS For This Useful Post:

Geezer (05-15-2014)

-

05-15-2014, 06:03 PM #3Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

The last set of photos is not as clear on the bevel as the first ones you took. Try to replicate that lighting conditions, those photos were amazing for a phone camera. Try to get the bevel closer to parallel to the lens.

Also when you photograph the bevels for comparison mark the razor with a dot of ink and record the same spot each time. You can use different colors or multiple dots if you are comparing multiple sections or sides. You cannot compare different parts of the blade, you must compare the same section of the bevel and edge.

Hone each progression in alternating angles for each stone so you can easily see if previous stria is removed.

For example hone the 1K straight 90 degrees to the edge, then the next stone at 45 degrees. Look to see if all the 90 degree stria is removed. Inking the bevel of the 1k will make it easier to see on the 6k stria, as it fills the deep stria and will easily show up on 6k stria if not removed. Colored ink is easier to see, as black ink can look like a shadow.

You really have to see in side by side comparison, to tell if you finish stones are finer than you 6K, or you are spinning your wheels.

Work systematically testing for one result at time, eliminating as many variables as possible. To say the Chrome Oxide is faulty when stropping a bevel with multiple levels of stria running in all directions from stones of unknown girt and partial size, is a false conclusion or at least very suspect.

Definitely not empirical, enough to malign a vendor.

Don’t discount your Chrome Ox until you get the honing down. But questionable purity Chrome Oxide will always be questionable. Contact the vendor and find out the purity or source.

Good, “Known Good” razor quality Chrome Ox is not that expensive.

-

05-15-2014, 06:16 PM #4

If u blackened the edge with a magic marker before you started on the next grit.. Then when u hit the next grit and the magic marker is gone from your bevel would it be a good indicator that you have replaced the prior scratch pattern with the current hone scratch pattern??

-

05-15-2014, 07:32 PM #5Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yes, only on high grit stones, maybe 8K and up.

Works well for high grit natural finishing stones. On high grit stones the ink is about the same thickness as the stria. And you are filling the stria with ink, so once all the ink is gone so is the previous stria, of course, YMMMV.

Inking works well when removing deep 1K stria by filling the bottom of the 1k stria and it shows up easily under the next progression if not removed.

The 1K is the most important stone and truly the building block of building an edge. And that is a good way to look at it, each step as a building block and each block must be straight, plumb and level or the top of the wall, (the edge) will never be straight.

-

05-16-2014, 03:05 PM #6

I understand what you are saying, not I'm not calming to be even good at honing I'm still a beginner. However when I hone a razor I always hone it in one direction, in the way that all the scratches are in the same direction. Now I have taken the razor from first post and I've stropped it on the CrOx but in opposite direction in a way that if the CrOx creates deep scratches on the razor they will be cross configuration and that is exactly what I have seen, so it must mean the scratches are made by CrOx.

I will try to capture the scratches however it is extremely hard process with the phone camera. About the pictures I have submitted yesterday I tried to replicate the lighting but clearly I was unsuccessful the only way to compare the scratch patter is if I would have access to microscope, then replicating the pictures would be much easier, the other option is just to see the after different stages in person. I have contacted the seller today as of his source of the chromium oxide hoever I still did not receive reply, I will inform you of whatever he says in the reply.

Regards Rafal

-

The Following User Says Thank You to RafalS For This Useful Post:

Blistersteel (09-09-2014)

-

05-16-2014, 03:07 PM #7

just quick addition I've stropped it maybe 5 time on each side.

-

05-17-2014, 11:32 PM #8Senior Member

- Join Date

- Jun 2012

- Location

- Miami, FL

- Posts

- 172

Thanked: 16

Interesting thread. I would try CrOx from a more reliable source to see if you get the same scratch pattern. I use CrOx from SRD, but I know you're in the UK and the shipping cost could be a problem. If Neil Miller sells CrOx I would get it from him.

-

05-18-2014, 12:51 PM #9

today I have received message from the seller

"Hi I am sorry you are experiencing problems, the particle size is around 1.5 -1.8 microns

I use it, 10 laps after honing, did use it mixed with a light oil for polishing but now use a green wax bar.

I can honestly say i have sold 100's of packets & yours is the first complaint, The wholesale advertises it as high quality & supplies to business

http://straightrazorpalace.com/srpwiki/index.php/Category:Stropping"

Here is the answer too the problem particle size is 1.5 - 1.8 microns

Regards Rafal

-

The Following User Says Thank You to RafalS For This Useful Post:

Geezer (05-21-2014)

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote