Results 1 to 10 of 12

Thread: Removing chips

Threaded View

-

10-31-2014, 10:19 PM #1

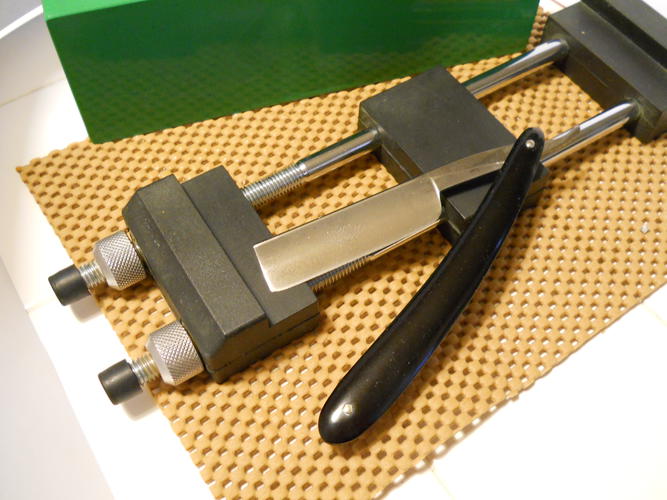

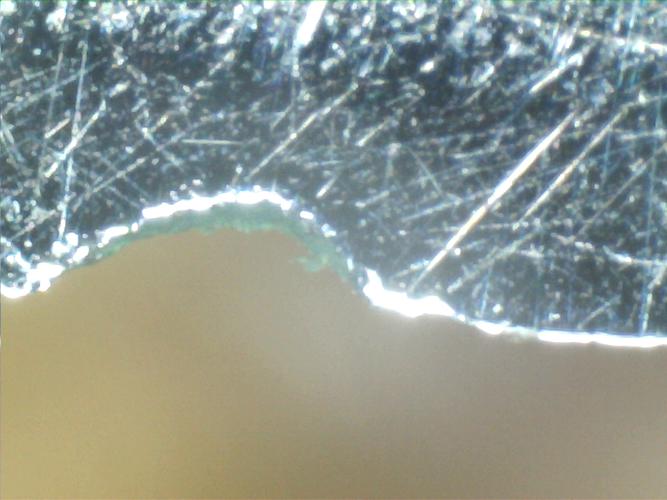

Removing chips

Removing chips

This J.R.Torrey came in the mail today via ebay. It is fairly good condition overall with the exception of the edge. It looks like someone did the "hanging wire test" on it. Should I breadknife the entire edge and then set a new bevel, or just treat it as a normal bevel set and hone it until the entire edge see's new metal ?

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote