Results 11 to 20 of 59

Threaded View

-

01-09-2015, 07:38 PM #1

Grit issues, does any one else see a problem here

Grit issues, does any one else see a problem here

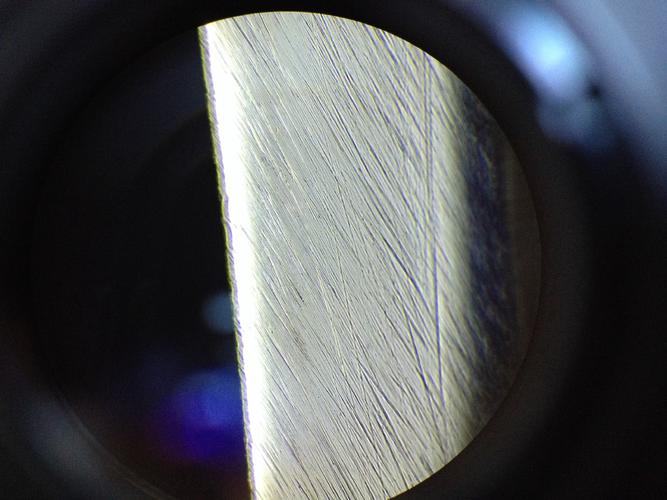

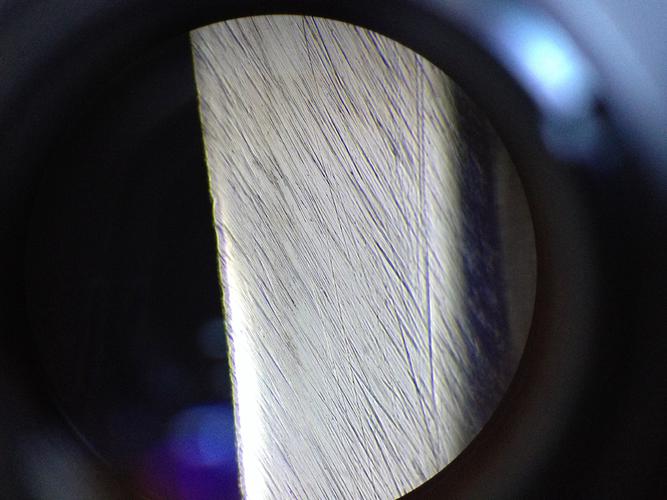

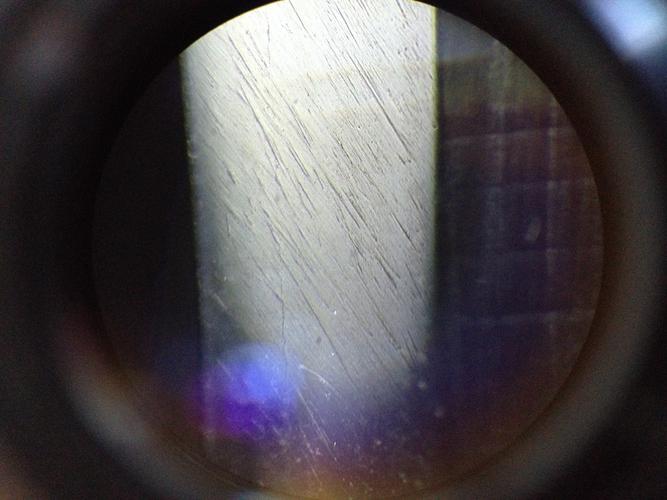

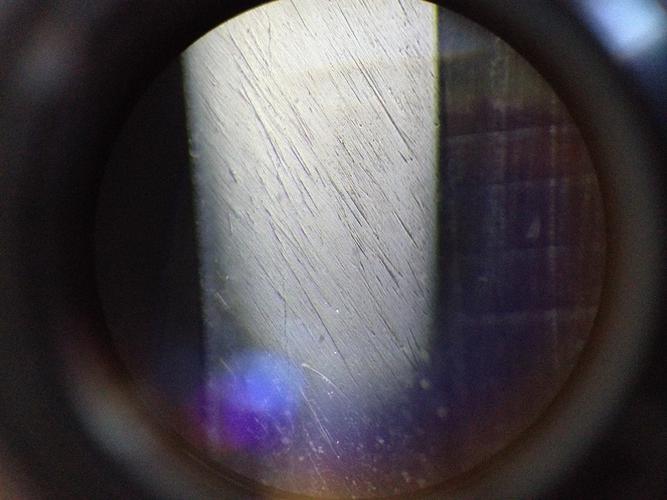

I have been looking at a knife edge for about an hour getting frustrated and scratching my head. Tell me what you see when it comes to the scratch pattern. Note please forgive the poor pics. It's hard to take a pic through a eyepiece and hold a light at the same time. These are done at 100x. The grits are 8k and 16k.

16k

8k

Again in sorry for the poor pics. Tell me if you see a problem. The pics are not switched and the 16k was freshly flattened with a DMT325 and rinsed/cleaned off the best I could.

Forgot to mention both of these are Shapton GSLast edited by rlmnshvstr8; 01-09-2015 at 07:41 PM.

A fool flaunts what wisdom he thinks he has, while a wise man will show that he is wise silently.

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote