Results 1 to 1 of 1

Threaded View

-

09-11-2015, 09:35 PM #1Junior Member

- Join Date

- Jun 2015

- Location

- Marlyand, USA

- Posts

- 26

Thanked: 13 Rolls Razor Honing Procedure & Test

Rolls Razor Honing Procedure & Test

I recently took a journey from DE to straight razor shaving. If you're interested, you can read about it in an article over on the Sharpologist's blog at One Man's Unusual Straight Razor Journey - Sharpologist

Although I completed the trip, I also discovered Rolls Razors which are essentially straight razors on a stick so the shaving experience is very similar to DE shaving. As a result, I picked up a couple of Imperial 2 kits (a Traveler in a brown alligator leather pouch and a blue-cased version). I then did some research on a variety of sources and figured out how to refurbish a Rolls including the friction pad assembly that maintains the correct pressure on the blade when stropping or honing. I’m now enjoying great straight razor shaves with my Rolls Razors.

As I got familiar with the Rolls, I of course came up against the issue of honing the blade. I’d read that the Rolls hone was about 4-6K grit so decided I would use the hone for emergency repairs rather than quality maintenance which I would do by hand. That lead to the question about whether and how much to tape the blade during hand honing. I’d read some posts on the subject, but never saw one that cited exactly how they determined whether or not to use tape or how much to use. It seemed like folks just made some assumptions and went with that. I decided to be more formal about answering the tape question.

After testing my two Rolls kits, it seemed one layer of electrical tape would be the right amount on the blade spine that would result in a hand-honed bevel that would match that created by the Rolls system. At first I thought it would take more because of the height at which the Rolls seemed to hold the spine above the hone. However, I also noticed that when you push the handle to hone the blade, there is sufficient slack in the design of the Rolls connections that the blade depresses so it’s closer to the hone (i.e. at a shallower angle). I determined the gap between the spine and hone by pushing strips of paper between the spine and hone until I felt some friction when I pulled the papers out while pushing the honing handle to hone a blade. As it turns out, one thickness of electrical tape matched the thickness of the papers from my gap measurement process.

However, I thought I’d take it a step further and do some testing to prove the point. I’d start with a blade either with no tape, 1 layer, or 2 layers of tape. Each time, I began the process by hand honing to set the bevel with my 1K grit stone. I did this by rotating the blade CW 20 times, then CCW 20 times, then repeating that set. I then honed it with a pyramid process using 4K and 8K stones starting with 15 double passes on the 4K then repeating that on the 8K. I then dropped to 10 passes, then 5, then 3, then 1 on the 4K and 3 on the 8K, and 1 on the 4K then 5 on the 8K. I finished the process with 10 double passes on my 12K polishing stone.

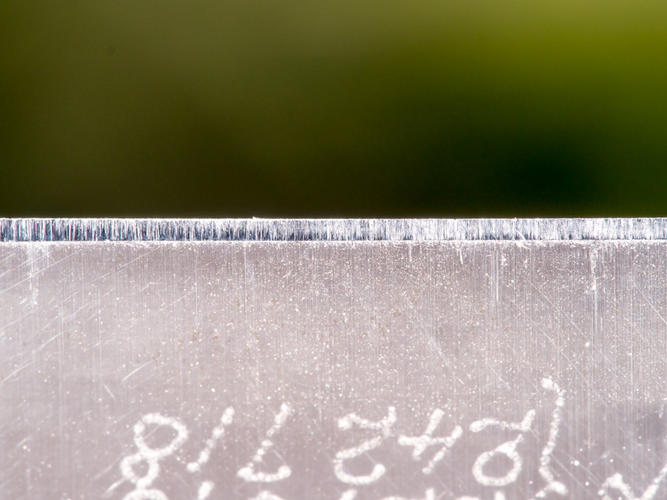

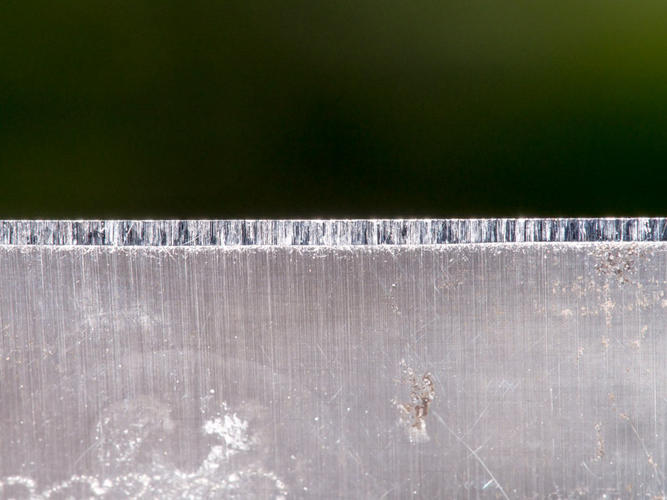

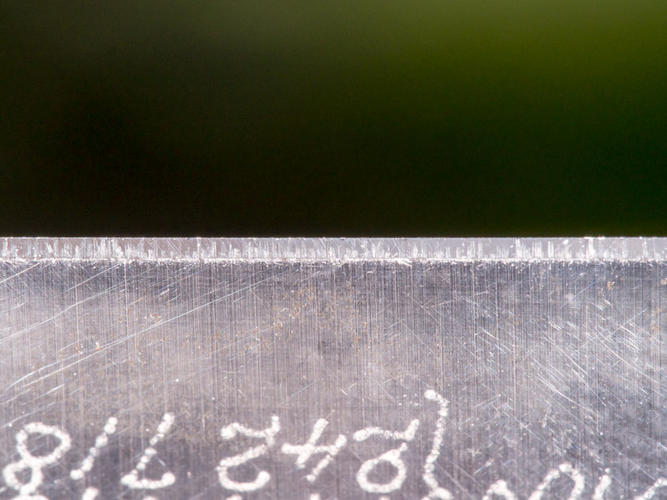

I now had a nicely honed and polished edge that would show the marks made by the courser grit of the Rolls hone so I would know when I had the right bevel angle. I honed just 10 double strokes on the Rolls at first to ensure I didn’t obliterate the polished edge. That let me see if the just the tip, the whole bevel, or just the base of the bevel was contacting the hone.

The results made it pretty clear to me that one layer of tape matches the bevel of the hone system (I used more than one blade and retested in another Rolls that I have). When I honed with the Rolls using an untaped hand-honed blade, the tip of the blade was clearly in more direct contact with the hone. When I used a blade hand-honed with one layer of tape, the entire bevel was scored by the Rolls hone. Finally, the hand-honed 2 layer blade was scored by the Rolls primarily at the base of the bevel.

The photos below show first how the polished hand-honed edge looked before a run on the Rolls. Then comes the blade edges after being honed with the Rolls system. First is a shot of an blade honed without tape, then blades that had 1 tape layer (2 photos of different blades), and finally a blade that had been hand honed using 2 layers of tape.

This processed convinced me that when I hand-hone my Rolls Razor blades, I will use one layer of tape. That way, if ever I have a need to use the Rolls hone, I'll at least be sure the bevel is correct. Hopefully, others will find this information useful.

Steve

Steve

Thistle Cutlery Co. 5/8; Rolls Razors (Imperial 2 & Viscount); Merkur 39C (Sledgehammer), Parker Variant

-

2Likes

2Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote