Results 1 to 9 of 9

Thread: Dull Heel

-

11-22-2015, 06:37 PM #1Member

- Join Date

- Dec 2014

- Location

- Charleston SC

- Posts

- 56

Thanked: 12 Dull Heel

Dull Heel

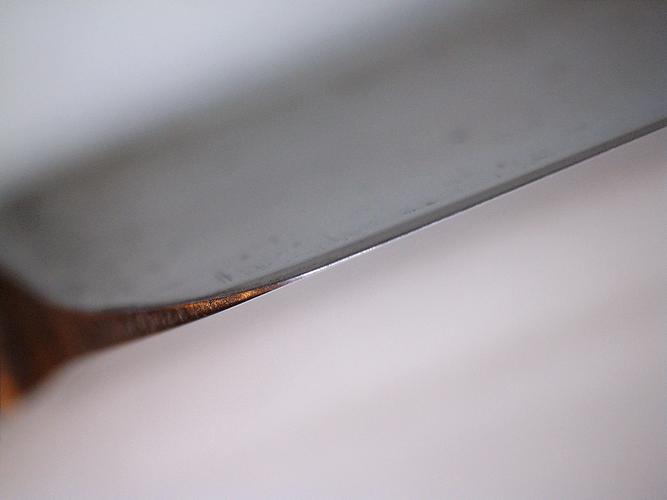

I have a W&B I restored awhile back and was unimpressed with the rescaling attempt I made. The razor sat on my coffee table for about a month with no scales so today I made a second attempt and was pleased with the scales but I have never been able to get the heel sharp on this razor and today was no different. I'm guessing its a 1/2 or 1/4 hollow and might have been sharpened too many times with the razor hitting the stabilizer. Now I need to figure out how to get the heel sharp. This is where yall come in

. A little help would be appreciated. Here is a pic.

. A little help would be appreciated. Here is a pic.

Thanks, Anthony

If it's worth doing, it's worth over doing!

If it's worth doing, it's worth over doing!

-

11-22-2015, 06:50 PM #2Member

- Join Date

- Dec 2014

- Location

- Charleston SC

- Posts

- 56

Thanked: 12

Here is a pic of the razor

If it's worth doing, it's worth over doing!

If it's worth doing, it's worth over doing!

-

11-22-2015, 07:18 PM #3Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

You are riding on the small stabilizer and tang and have created a double bevel at the heel. Mostly the heel is un-honed. You can see the wear marks on the stabilizer, when the photo is enlarged. You can confirm this with sharpie ink on the stabilizer, tang and heel.

Use a heel forward stroke and either put a little pressure on the heel ( a finger) or torque the blade toward the heel, just a bit it won’t take much, Or grind the stabilizer.

I would alter you honing technique.

Here is the stroke you should be using, Swooping X Stroke with the stabilizer off the hone, in the Library/ Strokes for honing a razor.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Anthonyb (11-22-2015)

-

11-22-2015, 07:42 PM #4Member

- Join Date

- Dec 2014

- Location

- Charleston SC

- Posts

- 56

Thanked: 12

That's what I tried to do and managed to make the bevel much wider at the heel but still not meeting. This was a problem that existed before I got the razor and not sure I can fix it. I don't usually use that part of the blade so it is easy to ignore but I would like to fix it. Maybe I should go grind away on it some more.

If it's worth doing, it's worth over doing!

-

11-22-2015, 08:11 PM #5Member

- Join Date

- Dec 2014

- Location

- Charleston SC

- Posts

- 56

Thanked: 12

OK ,I went back to the 1k and used firm pressure on the heel and got it to shave hairs, going to go up through the grits and see how it goes. Guess I was just to reluctant to keep honing away at the heel. The bevel is wider there but at least the bevels meet!

If it's worth doing, it's worth over doing!

-

11-22-2015, 08:15 PM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Ink will tell you if you are hitting the stabilizer, the secondary bevel is clearly at a much higher angle. The stabilizer is shallow and it is easy for it to ride up on the stone, if you add pressure while the stabilizer is on the stone, it will make a secondary bevel, just like you have.

Go slow and keep the stabilizer off the hone, heel forward. The heel is a very useful part of the razor, you should be using the whole razor to shave.

Keep the heel on the stone until at least half way across the stone, more than in the demo. So the heel is getting more honing, or you could do a full heel forward stroke to hone the heel, you will have to swing the toe around to get the full radius of the heel though, in subsequent strokes.

-

11-22-2015, 08:19 PM #7Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

You also will have to be careful not to make a point on the heel, it is kind of square-ish already too much pressure can make a point and even a hook, they will cut you.

I would round the profile of the heel more to a dime radius then re hone the heel to get the bevels to meet.

-

11-22-2015, 08:47 PM #8

Some of these blades were honed on narrow hones in contrast to the flat wide hones we mostly use today.

In your mind focus on the near 3/4inch of the hone and use a heal first swipe stroke. Use magic marker ink

to see if the hone and steel are doing the right thing.

Do not feel a need to fix it.

Keep an eye out for some of the knife sharpening folk that cut hones into skinny

slices to fit on special sharpening jigs. If and only if the price is very good grab some

in the 4K and finer range.

Or stand a hone on edge and use the side of the hone.

Once you get a blade like this sharp just maintain it (8-12K) and never let it get dull.

Regarding narrow keep an eye out for a nice but skinny/narrow Belgian Coticule.

Sometimes the narrow ones are priced at friendly prices.

Diamond, CrOx, and other abrasive paste on 1/2"-3/4" hard maple strop stick can work too.

-

The Following User Says Thank You to niftyshaving For This Useful Post:

Anthonyb (11-22-2015)

-

11-23-2015, 01:22 AM #9Member

- Join Date

- Dec 2014

- Location

- Charleston SC

- Posts

- 56

Thanked: 12

I took a break from it. I got it back to shaving but there is a point developing on the heel. I will probably use it till the next time it needs honing and hone the point out. This is my favorite razor for head shaving a different haven't gotten to use it for a while. Thanks for the help!

If it's worth doing, it's worth over doing!

4Likes

4Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote