Results 1 to 10 of 23

Thread: Tape wear and Bevel

-

12-14-2015, 11:38 PM #1

Tape wear and Bevel

Tape wear and Bevel

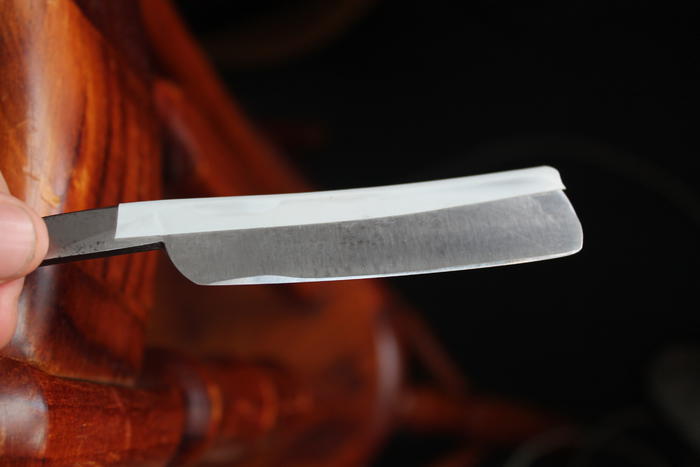

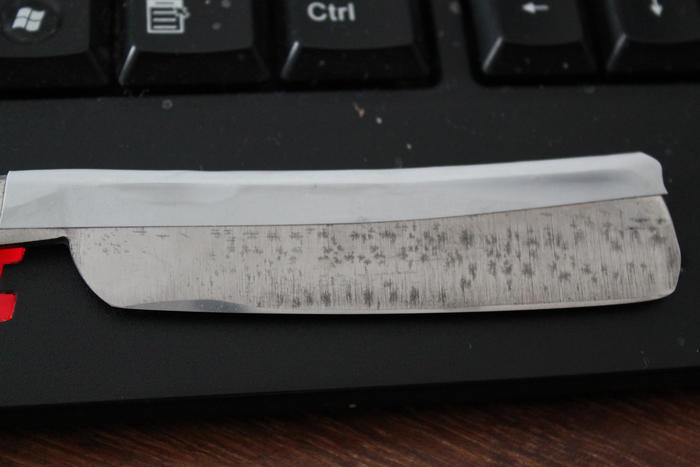

Hey all, just after some advice. This is my first wedge and I'm just hoping you could sneak a peak at the bevel. One side (the front) is quite even, it narrows as it reaches the heel. The rear side however has a section where the bevel is double, nearly triple the length of the rest of it. I have included some shots where you maybe be able to see the tape wear as well along the spine.

I'm curious as to what is causing this and is it an issue? The grind is near wedge, you can see some light through the razor as it's laying flat on the hone. Hones have been lapped, currently using 1K Suehiro ceramic. It was cutting hairs on my arm well so I gave it a bit of time on the 3K and is now cutting hairs more smoothly. Is it possibly the grind itself causing the skewed section or is something amiss? More tape?

I'm wary of taking the tape away entirely because these stones really cut fast and the spine would start or thin out rather quickly...

Cheers lads!

-

12-15-2015, 12:25 AM #2Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

It's not from the tape. That difference you will never see. It looks to me like your blade was reground at some point and the wide bevel is due to the thickness of the blade in that area. In other words ... it wasn't ground even all the way.

Where the bevel is wide, the blade needs to be thinned.

OR.... The blade is warped. Which would show equally the opposite on the other side. Sort of does. A straight edge held next to it will show the warp.

This is all off the top of my head but what I see at first.Good judgment comes from experience, and experience....well that comes from poor judgment.

-

The Following User Says Thank You to 10Pups For This Useful Post:

andrewmurray86 (12-15-2015)

-

12-15-2015, 05:46 AM #3

I think the blade could be warped... I didn't have a straight edge handy but the edge of the desk shows a slight convex in the side with the thicker bevel section.

What sort of issues will that cause? I've been fairly happy to move it to the 3K and would happily continue up until it is shave ready. I'd happy shave with it as long as I'm satisfied with the honing progression.

Would you recommend doing so or nah?

-

12-15-2015, 07:24 AM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

If you check the apex with a loupe and all is well there then the issue is purely cosmetic. You can create a spot like that with a bunch of pressure trying to get a stubborn spot. By adding the pressure though you can never get the trouble spot and you push it a little more and it just cuts above the edge and compounds the problem. It is an unlikely scenario in this case. I think Pups hit it on the most likely case. A lot of old razors have been reground, especially the wedges.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

andrewmurray86 (12-15-2015)

-

12-15-2015, 08:02 AM #5

My theory is that you may have an uneven relationship between the spine and the edge. If that is true, you'll have to set the bevel without tape on the spine. The spine and the edge have to be parallel for a good bevel set. If you tape the spine, you'll never correct any deficiencies on it.

-

The Following User Says Thank You to Wayne1963 For This Useful Post:

andrewmurray86 (12-15-2015)

-

12-15-2015, 08:07 AM #6

Andrew, if you've got the two bevels meeting and the edge passes the thumb nail test for smoothness, I'd go on to the finer hones. The appearance of the bevel, while not ideal in this case, is always secondary to the shaving ability of the razor. As the other guys have said, who knows what sort of regrinding or general edge abuse has been inflicted on this razor in the past. About half of the wedges I've honed have had issues of this sort in greater or lesser degrees and they've all finished up able to cut those whiskers down to the skin!

-

The Following User Says Thank You to Maladroit For This Useful Post:

andrewmurray86 (12-15-2015)

-

12-15-2015, 08:54 AM #7< Banned User >

- Join Date

- Dec 2013

- Location

- Perth, Western Australia

- Posts

- 318

Thanked: 44

I agree that it's probably uneven grind, but if you look at the third picture you can see that the abnormal shaped area of the edge is mirrored in the tape. Looks like a bubble?

-

12-15-2015, 09:17 AM #8

-

12-15-2015, 10:23 AM #9

Check the apex= Use a loupe to look straight down on the edge, at the cutting edge itself, not the 'sides' of the bevel. The point of the triangle so to speak.

Last edited by WW243; 12-15-2015 at 10:25 AM.

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

The Following User Says Thank You to WW243 For This Useful Post:

andrewmurray86 (12-15-2015)

-

12-15-2015, 10:33 AM #10

I have a Blue Wonder that just won't take a bevel, have looked at the apex many times on that... I haven''t tried tape on it though. My brother currently has it as a template for some stainless scales I want fabricated for my Birko Razor... Which he also has. I should get them back me thinks. I doubt he's going to get around to doing them before a while, God love him!

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote