Results 1 to 10 of 33

Thread: Setting bevel

Hybrid View

-

01-05-2016, 10:57 PM #1

-

01-06-2016, 02:38 AM #2

Here....

Exactly. Some people call it a micro bevel and it is done with knives and quite a few here will use it with razors too although they will start with a layer of tape for the bevel set and honing but when they are going to their finishing stone they add one more layer to get the micro bevel. I have never used this method but there are some that swear by this.What a curse be a dull razor; what a prideful comfort a sharp one

-

01-06-2016, 03:00 AM #3< Banned User >

- Join Date

- Dec 2015

- Location

- Calgary

- Posts

- 43

Thanked: 3

-

01-06-2016, 04:42 AM #4

-

01-06-2016, 05:29 AM #5< Banned User >

- Join Date

- Dec 2015

- Location

- Calgary

- Posts

- 43

Thanked: 3

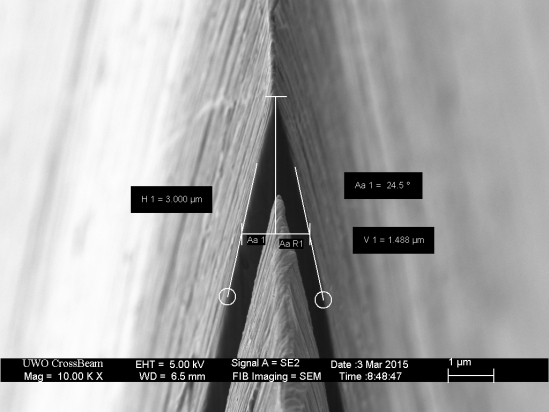

I think it was the first time I was looking into getting a Yanagiba, something I read explained the bevelled side as having a double bevel, but it's really a primary and secondary bevel that blend to make one big curved bevel:

(from: Bevel angel for Takobiki or yanagiba? 300 ish mm)

For those scratching their heads over another puzzling Japanese word - Hamaguriba is the term for the continuous slight curve of the primary bevel.

It curves all the way to the edge, with no actual secondaries. This is often called a Moran grind, or the old Japanese term - Appleseed grind.

It is formed by making small flats as you sharpen/shape the bevel on the stones. Each flat is "blended" into the next one until the bevel looks like a smooth surface. When it meets the edge, it ends as a zero-grind. This technique was very important in shaping Japanese swords and knives made from the traditional billets with a hard edge and soft body. The steel sharpens very differently depending on the carbon content, and blending them together improved both ascetics and performance.

I find hamaguriba not a necessity in modern Japanese kitchen blades when using modern grinders and steels. The final edge seems to take care of itself when doing the final sharpening steps ( shiage-togi) by lifting the spine as you stroke the last few times on the edge. Some use a mouse pad backing on super-fine papers to get this effect.

Using a Rotary platen also creates a slight curvature of the bevel, quite similar to hamaguriba.

-

01-06-2016, 06:09 AM #6

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote