Results 11 to 13 of 13

Thread: ceramic hone

-

03-20-2016, 02:54 PM #11

I thought about wear on the plate to and that is why I used little pressure and lots of water hoping that I didn't dig the diamonds out of the matrix. That plate had a few high diamonds in it before. We will have to see. The only way I could get more of this is to cut it in pieces. As he is getting older Jerry has been passing on a few of his things to me as he knows I will play with/use them.

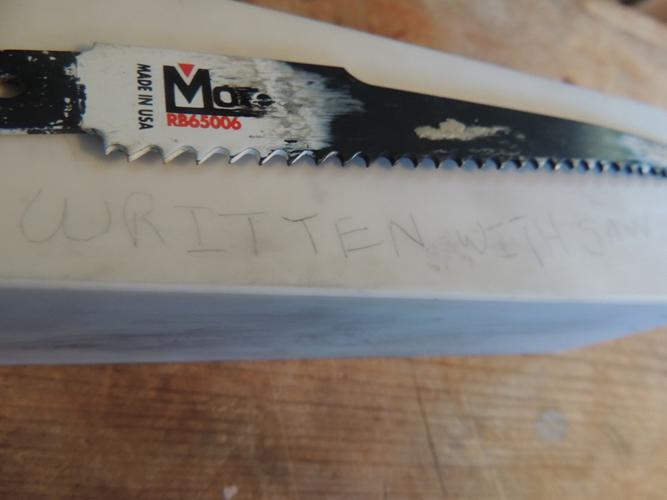

I am just beginning to experiment with and it is fairly fine but it removes metal.

You could use it for a note pad in a pinch.

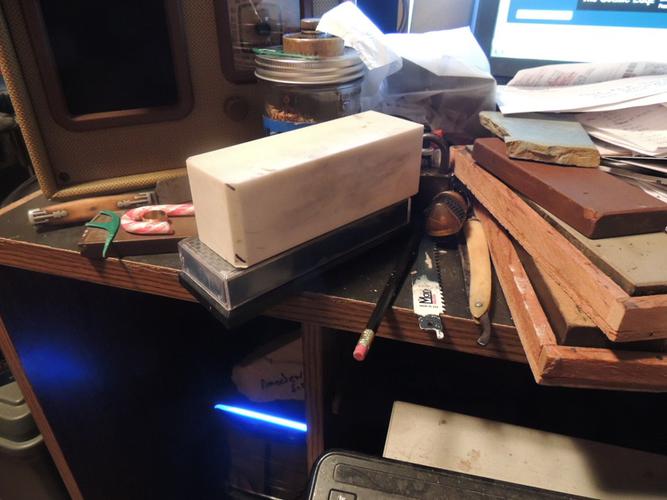

Why would I do that and not just use/find a pencil you may ask. Here is a corner of my desk!

-

03-20-2016, 04:44 PM #12Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Nice one! Haha, love it. Good luck with it. What grit was that diamond plate BTW? You may want to take the surface finer if you want to use it to finish razors. Leave it coarser for pocketknives though. Ceramics finish edges differently depending on surface finish (like many very hard stones). With that big boy you could have a different finish on every side for different purposes.

-

03-20-2016, 07:20 PM #13

I used a 400 Atoma. Good idea to have 4 different sides. I will have to look into that further.

23Likes

23Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote