Results 11 to 13 of 13

Thread: Stainless steel razor honing

-

07-18-2016, 08:00 PM #11

-

07-19-2016, 09:11 PM #12

Unfortunately, when I got this razor, I didn't photograph it to get a baseline. However, looking at it now, I see some things at very high resolution.

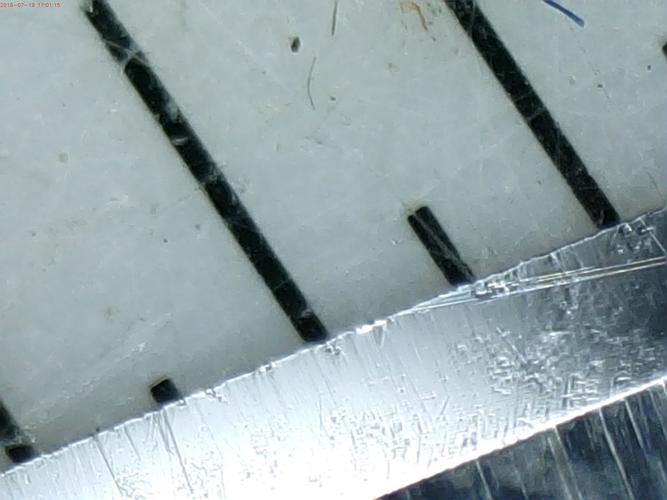

First, near the heel, there is an area where the narrow to start with bevel narrows even more and then gets larger (not to the amount of the toe. So you see a bevel from a lower grit, and then a bevel from a higher grit, which is the same width, until you get within 3/4" of the heel then the higher grit bevel is smaller. Oddly, on the other side (right as you look at the edge), the bevel is even all the way across. The spine wear is more in the front third of the blade and almost no wear on the last third (toward the heel).

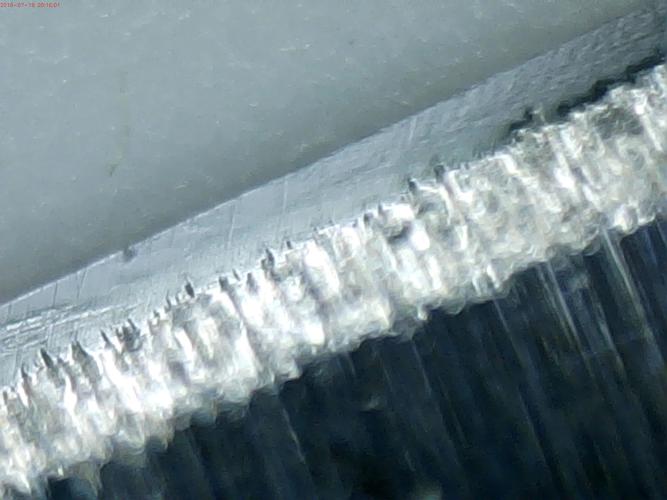

Second, there seem to be some really small flat spots (the ticks on the ruler show are 0.5mm wide). Near the toe, there seems to be some very small chipping maybe?

I'll try some stroke on the 12K and see if it can get rid of the flat spots.Regards,

PCM

-

07-20-2016, 12:19 AM #13

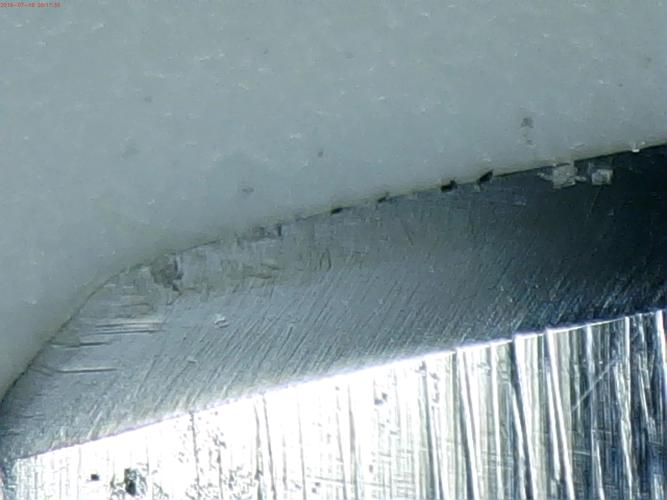

I tried 12k, but the small divots and flat spots were still there. I dropped to 8K and was able to get them removed. I had to apply extra pressure at heel and toe, to get it to make contact, and I tried to improve some on this odd spot on the left side near the heel, where the bevel is narrower. It's a tiny bit better, but not too much. I used two layers of tape and it seemed to match what was on there for the final bevel (not the lower grit bevel area as shown above.

Really odd bevel on this one. One side straight, one side tapered smaller from toe to 2/3 of the way, and then increases to the heel. It wasn't too much harder to make progress with the hone, as compared to the other blades. I thought the Stainless would be really hard to hone off metal.

I'll test shave it Thursday and see how it feels. Should be better. I also touched up two other razors (just with the 12K) and need to check them out as well.

Here is the problem area, and a shot of the toe - you can see the bevel is not very wide at the tip - I tried a bit of a rolling X to get to that part.

Regards,

Regards,

PCM

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote