Results 1 to 10 of 12

-

11-01-2016, 10:35 PM #1

Hone flatness using a bevelled straight edge

Hone flatness using a bevelled straight edge

hello everyone hope you guys are having a nice day.

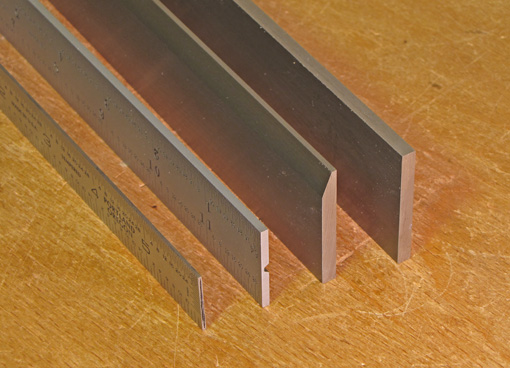

i am recently in the process of becoming overly concerned about the flatness of my stones and so i have purchased a bevelled straight edge, which looks like the picture.

now before you say this level of flatness is not important i am aware of the fact, but for reasons beyond me it is important for me to get the stone as flat as i can.

so now to my question, i have been reading and it seems the best method to use the straight edge is to place it on top of the surface and shine a light from the other side of it and if light is seen then the surface is not flat.

my problem is that because of the knife like shape of my straight edge light is shining no matter what surface i am testing(my DMT, plates of glass etc.) and so this method of evaluation doesent seem to work as i am unable to differentiate between flat and not flat .

anyone familiar with these have another solution or tip for the proper usage of the straight edge ?

thank you for any input .

-

11-01-2016, 11:17 PM #2Junior Member

- Join Date

- Mar 2016

- Posts

- 26

Thanked: 16

It doesn't work on diamondplates, the diamonds are too much exposed and there will always shine light inbetween the diamonds and reflect on the nickelplated sheet. Glass is smoother, but in a shallow angle, the light reflects from the surface and most of the time you cannot see if it's flat. It works fine for non reflective whetstone surfaces, every lightspot means more than 10µ gap. Even my fine siliconcarbide stones get flat with less than 10µ gap on a 150 grid diamondplate.

-

11-01-2016, 11:40 PM #3

I have a Starrett # 385 straight edge and it has a bevelled edge, but it is not a V shaped knife edge. Rather the bevel squares off at nearly a 2mm flat surface. So that when I lay it on a stone it will be easier to judge flatness.

I don't shine a light behind it. I hold the stone with the straight edge in place up towards a light source (fluorescent strip above me) and eyeball the flatness that way. I don't know how it would be if it were a knife edge. However, this straight edge is a machinist's tool, with a high degree of accuracy. Are you positive that your edge is absolutely straight ?

Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

11-02-2016, 01:43 AM #4

azourital, is your straight edge tempered steel, or plastic?

-

11-02-2016, 03:53 AM #5

-

11-02-2016, 04:54 AM #6Previously lost, now "Pasturized"

- Join Date

- Oct 2005

- Location

- Winnipeg Manitoba Canada

- Posts

- 1,333

Thanked: 351

Daylight is sufficient for straight edge use.... blue sky or overcast sky, not a point source like the sun, flashlight or lamps. Soft lightling such as a white ceiling with fluorescent tubes are also used.

A quality straight edge is not meant to be used on abrasives! One slip and the straight edge is no longer a true straight edge! Knife edges like the one you have are very easy to damage, so if it were me.... I would keep it far far away from a diamond plate.

Now, if we are checking a surface, a small piece of paper at one end, under the straight edge will let you see the light shining between the straight edge and the surface you are checking and give you an idea of what you are looking for.

As someone else mentioned, you can NOT test a diamond plate with a straight edge as the diamonds will allow light to go between the straight edge and the surface of the plate which is beneath the tips of the diamonds and that surface is irrelevant as it is the surface created by the tips of the diamonds that matters.

Correct lapping with a trusted lap and a pencil grid on the surface of the stone you want to ensure is flat will be far more reliable and accurate than a straight edge in this case.

The straight edge is for use in machine shops and the like.... checking metal surfaces, and typically a feeler guage strip is used with it to measure the amount of hollow. There are special knife edged straight edges that are used for checking other straight edges... but these are typically very expensive, made from hardened steel and *only* used to test other, less expensive straight edges."Aw nuts, now I can't remember what I forgot!" --- Kaptain "Champion of lost causes" Zero

-

11-02-2016, 05:12 AM #7

Flatness isn't super critical if your strokes are on a point-by-point, lateral bias, rather than a stict, up-and-down approach. (And following this, not so many razor spine-edge relationships are all that flat out of the box, I would venture.) That said, the best way to test for flatness on the stone/hone in my opinion is to place the steel rule (basic Empire rule from Home Depot is fine) along the diagonals of the honing surface and attempt to slip a piece of stainless steel, 1/1000"-thick, feeler thickness gauge tape (available from McMaster-Carr) underneath. This is followed by the same test along the length-wise axis. If the tape passes underneath the rule, the hone in question is not strictly flat.

Last edited by Brontosaurus; 11-02-2016 at 05:21 AM.

Striving to be brief, I become obscure. --Horace

-

The Following User Says Thank You to Brontosaurus For This Useful Post:

Dachsmith (11-05-2016)

-

11-02-2016, 06:47 AM #8Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Vic, the straight edge picture in the first post says "INOX" so it is stainless steel - hopefully quenched and tempered to a decent hardness.

The best way to check for flatness with a straight edge is to use feeler gages. Looking for light is not quantitative and doesn't give an accurate idea how far the item being tested is out of flat.

To do this, use 2 pieces of paper or other items of uniform and equal thickness to support the straight edge at either end of the item being tested for flatness, then use the feeler gages to measure the gap in the middle. If you want to check very closely (not really necessary for a hone), check along the length, along the width and diagonally. Personally I like my stones to be no worse than .002" out of flat for razor work.

-

11-02-2016, 09:05 AM #9

wow thank you guys for the very informative replies i will definitly use the information.

i was thinking of the risk of putting a straight edge on a diamond plate especially a bevelled straight edge and i was very careful when doing so.

as far as your questions i have the PREISSER Precision Straight Edge, the accuracy is DIN 874 GG-00 standard (German industrial standard), which works out to be 3/1000 of a millimetre.

it is made of hardened, steel alloy.

thank you,

Dr. Tal Azouri

-

11-02-2016, 01:07 PM #10

I have a series of DMT 8" plates in different grits . In order to check them with my straight edge I flipped them over and checked the bare metal bottom side. I found the 325, and the 1200 were not what I considered flat enough.

I called Dia-Sharp and arranged to mail the two plates back for testing. They agreed that the 325 was not within their specifications for flatness, and replaced it with a new plate. They returned the 1200 saying that it was within tolerance.

I have 120, 325, 600, 1200, and what they call 8000. The 600 is the only one, going by my straight edge, which is dead flat. The others are close, but no cigar. I must also add that Dia-Sharp does not use a straight edge to check for flatness. They use a laser system IIRC. Anyway, I guess it is close enough for government work. Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

16Likes

16Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote