Results 21 to 30 of 50

Thread: A tape-free experience

-

12-28-2016, 04:46 AM #21

No doubt it is doable with the Arks, or other naturals. After all, when those old Sheffields were made it was common for Arkansas stones imported into Great Britain to be used for honing razors. Not to mention the Charnleys, Scotch hones, slates and what have you. I'm sure the USA folks were using them too. It is just that it takes a lot more time and patience.

A few years ago I took a shave ready Theirs Issard Super Gnome that needed a touch up to a La Veinette coticule. An 8x2 from Ardennes. The La Veinettes have the reputation of being one of the fastest coticules. I made a mark on paper every set of five round trips. I stropped after every 30 round trips and tried HHT. It took me over 160 round trips to get that razor where I felt it was satisfactory as far as HHT was concerned.

That razor turned out to be one of the best shaves I've ever had. Equal to any honed with any hone I've shaved with. OTOH, I started out with a basically shave ready razor that needed a touch up. Had it needed to have the bevel set and go on from there I'd probably still be honing it. Whether that was the fault of the hone, or the honer, I leave to the reader. Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

12-28-2016, 05:19 AM #22

-

12-29-2016, 11:07 PM #23Senior Member

- Join Date

- Nov 2014

- Location

- Sacramento

- Posts

- 309

Thanked: 135

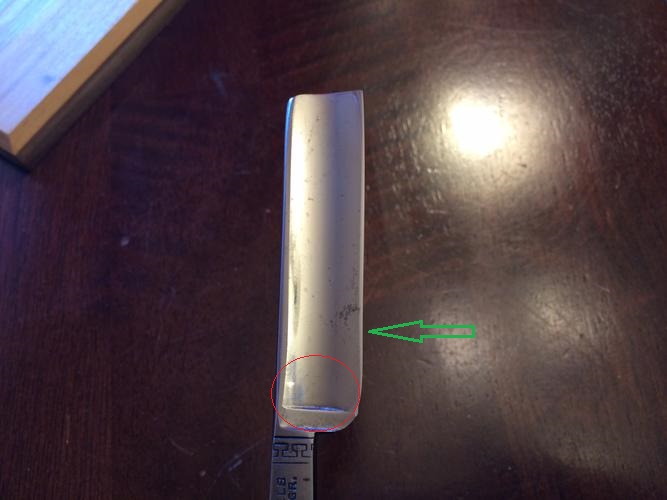

I took some pictures today of the Engels and would really love to get some feed back on what you all think.

I've now had three shaves since working on the edge, the last being this morning (still comfortable). I looked the edge over with a loupe when I got home and did notice a few tiny chips in the same general area as before; hard to see with 40x loupe but visible.

Also while looking at the pictures (I do apologize for the terrible quality of the pics, best I can do at the moment) I noticed the hook in the heel. I looked at a photo I took back in November 2015 and the hook was there then but now seems a bit more pronounced. I can see where the edge is cutting into the stabilizer?

There was discussion on another thread about addressing a hook in the heel. I probably would not try and profile a semi circle on this but maybe just try to smooth it out by honing. How would you do this without affecting the rest of the bevel?

Looking at older photos I think some active rust is happening in the deep pitting on the spine and other areas (one area is pushing against the bevel). This razor had bad rusting when I sent it in for a light restoration. I now think I should have been protecting it better; maybe leaving a light coat of oil on it after drying.

From pictures I've seen of scale rot; this does not seem to be a case? The blade actually looks better where protected by the scales. Thoughts?

Thanks for looking and sharing your thoughts.

PaulLast edited by Paulbuck; 12-30-2016 at 12:23 AM.

-

12-30-2016, 01:14 AM #24

I don't have first-hand experience with blade chipping caused by anything other than the faucet. The hook can be fixed with a small dmt or the edge of your bevel setting stone. Might take a bit to get it down to a smooth radius.

-

The Following User Says Thank You to KenWeir For This Useful Post:

Paulbuck (12-30-2016)

-

12-30-2016, 01:17 AM #25

Last edited by onimaru55; 12-30-2016 at 01:20 AM.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

The Following User Says Thank You to onimaru55 For This Useful Post:

Paulbuck (12-30-2016)

-

12-30-2016, 02:49 AM #26Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Paul, in the last pic you can see the uneven edge at the heel, caused by the stabilizer.

You must reshape the heel and move the corner forward of the stabilizer. It only takes a few strokes on a diamond plate or a Washita should do it, use the side.

It also looks like a frown where that rust pit is. Actually, the edge looks S shaped, narrow at the heel, wide mid-way above the pit Green Arrow and narrow below the pit, green arrow.

Put the edge on a flat surface and look at it for straightness.

Take a measurement at the narrowest point and mark a straight line from that point with a sharpie. A few high angle strokes should bring it back into line

Then just round off the hook, (red circle) to where the frown is and straighten the edge with a couple high angle laps.

Or if you want, send it to me and Iíll fix it for you.

-

12-30-2016, 02:59 AM #27

Spine wear looks a little heavier at the green arrow

-

12-30-2016, 03:06 AM #28

I don't know what that razor looked like when you first got it, but it is now a poster child for why taping the spine is advisable for beginning honing.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

12-30-2016, 03:26 AM #29

I'm wondering if maybe the blade isn't quite straight. Looking at the uneven spot on the spine & what appears to be a bit of frown, that's what comes to mind.

-

12-30-2016, 04:05 AM #30Senior Member

- Join Date

- Nov 2014

- Location

- Sacramento

- Posts

- 309

Thanked: 135

77Likes

77Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote