Results 21 to 30 of 37

-

01-12-2017, 05:15 AM #21Junior Member

- Join Date

- Jul 2012

- Posts

- 26

Thanked: 0

Thanks! Appreciated.

-

03-10-2017, 06:54 PM #22Junior Member

- Join Date

- Jul 2012

- Posts

- 26

Thanked: 0

Hi all, I just wanted to follow up here. I finally took my blank to the shop and followed some suggestions provide here. I started off with a new blank, not the one previously worked on.

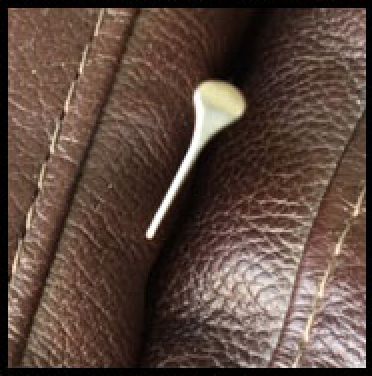

So I started first on the bench sander, using the curved part of the front of the sander. I was able to sand down approximately 50% of the blade from the edge. I couldn't get any closer to the top as it started to sand down the edge. So I had a 'point now, but wanted to attempt to get the blade more of a straight line down to the edge. I decided the only way to do this would be hand sanding. After my fingers started cramping up I managed to smooth the transition at the point where the bench sander stopped. At this point I proceeded through the usual steps on my Buffer using 6 different compounds. So what I have now is a Faux Frameback, but the sides of the blade don't come absolutely smoothly down to the point. However there is plenty of clearance now that honing is possible and should be for many hones to come.

My next task will be to figure out a way to get a straight drop to the point from the back. Not sure how to do this given that both my bench grinder, sander, and my buffer rely on a curved grinding surface, which inherently keeps it from getting right up to the Frameback (see Pics Below). I may try and only use the very side of the top of my bench sander, using the flat top portion. This will require some very delicate handling. Other than that I am open to suggestions. BTW, the scales are faux ivory. I expect that by the time I have finished all 4 of these blanks the last will be the best. Cheers

-

03-10-2017, 07:02 PM #23The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,736

Thanked: 480

I think Geezer once said he ground one of these on an old Wen Hollow Grinder knife sharpener. Nobody says you have to hollow grind it. I would consider it a fun experiment

-

03-10-2017, 08:11 PM #24Junior Member

- Join Date

- Jul 2012

- Posts

- 26

Thanked: 0

I just looked at one on EBAY. Seems I still have the problem of the curve not allowing me to get up tight to the spine.

-

03-11-2017, 05:20 PM #25Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

It will be difficult without the same tool originally used. Most likely these were ground at the factory by hand using a double wheel grinder that was adjustable for center to center distance between the wheels. They would have used fairly small radius wheels to get up near the spine. See here:

https://youtu.be/BBoI1hmYfbs

Alternatively you can try a setup like this if you only have the usual one wheel sander:

https://youtu.be/apjtYokzgk0

-

The Following User Says Thank You to eKretz For This Useful Post:

Marshal (03-13-2017)

-

03-11-2017, 06:58 PM #26Junior Member

- Join Date

- Jul 2012

- Posts

- 26

Thanked: 0

Great videos! Very informative. LOVE that 2 grinder setup!

My only problem is that my blanks are Faux Framebacks, and as such the curve of the grinding wheels, even if very small, still won't allow me to get right under the Spine. That is okay though, I'll keep experimenting and see if I can't come up with a solution.

-

03-11-2017, 08:01 PM #27

That's how I grind my blanks before I heat treat.

-

03-11-2017, 09:34 PM #28Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Sure they would, as long as the right diameter wheels are used. A radius is a radius. In many cases, multiple sizes of wheel were used on the same razor to get differing effects. Aside from all of that, they are razor blanks, and can be made into whatever grind you like.

Last edited by eKretz; 03-11-2017 at 09:37 PM.

-

03-11-2017, 09:47 PM #29

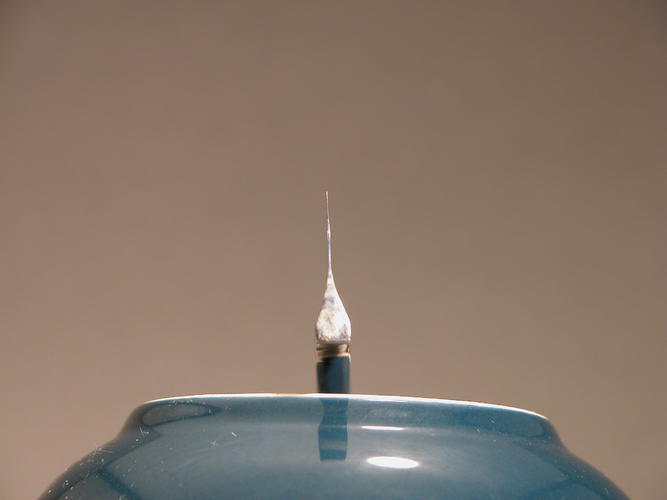

This is done with an 1 1/4" wheel. It is a 6/8.

-

03-11-2017, 11:14 PM #30

30Likes

30Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote