Results 1 to 9 of 9

15Likes

15Likes

Thread: Honing a new out of the box razor

-

04-15-2017, 03:11 AM #1Senior Member

- Join Date

- Nov 2013

- Posts

- 758

Thanked: 104 Honing a new out of the box razor

Honing a new out of the box razor

It's exciting opening that new razor, following the manufacturer's instructions, having the shave and end up disappointed with the edge. This is more the rule than the exception. What do we do? Re set the bevel, go back to the start, strop then try again, or maybe back to say a 5k and gently go to finishing hones. A lot depends on the razor brand, Dovo, Thiers Issard or other well known 'new' razors. A lot depends on the individual razor, most claim shave readiness but I'm sure that it's probably a 10% of them can shave 1st up. Ok, we can open it up. 1st look at the edge under magnification, it will at the least show you if the razor has been hand honed, with or without tape. Many tests exist as to sharpness, most work, after trying them all, looking at others results, I think the simple cherry tomato test is good. Personal choice. Most recently I bought two identical Thiers Issard 7/8 razors. The edge/bevel on one was bad, looked like it had been hand honed, untaped, and a frown and a chip in the toe, it failed the cherry tomato test. It was certainly direct from the factory. It took a fair bit of work, a complete bevel re set, but I got it right in the end. The second one was also hand honed, no tape, but an even bevel, no chips and it passed the cherry tomato test. Experience will tell you from magnification as to its readiness for the bathroom. In this razors case I felt it was nearly there, but not quite, only experience or a shave test will answer that.

I, having seen evidence of hand honing,and doing a sharpie test told me they used no tape. So on this occasion for this razor, I used a Naniwa 10k superstone, for 10 very light strokes, followed by a similar number on the Suehiro Gokumyo 20k. Stropped and shaved. It was great. So same two brands of razor, very different methods. One took 10 minutes, the other hours. So the moral to this story is look at it under a loupe or similar and test for bevel sharpness. If you have that, no need to go back to the start, but you might need to treat it as though it was a razor of yours, that had just started to tug, so all it needs is what you'd do for a touch up. The middle ground is one that passes bevel set, but in your opinion is beyond a simple touch up, then maybe a move from a 5k or 8k to your finishing stone. Some people just say, well most of the time just reset the bevel, then you know what you have from day one. So, a valuable tool for people who get a new razor, is the magnifier, sets you on the right path, helps you assess the razor, especially if your not super experienced, the sharpie answers the tape question, and loupe let's you confirm that because the spine will show hone marks if untaped. And it's probably wise, if the thing passes the tomato test, shave with it. Most razors won't be very bad from the factory and need a full reset, the touch up technique is good for say 7/10. Good honing.

-

The Following 3 Users Say Thank You to bobski For This Useful Post:

MedicineMan (04-15-2017), ScoutHikerDad (04-15-2017), tinkersd (04-15-2017)

-

04-15-2017, 10:18 AM #2

I've bought three new production razors in the last year: the first was a TI Special Coiffeur 6/8 - it was rubbish out of the box and took a lot of work to get a new bevel set; the second was a Boker Carbon Elite 6/8 from SRD: the edge was good but benefited from a trip over my Arkansas hard black; the third was a Hart 7/8 round point: no fault found initially and the shaves were superb, but close inspection later on revealed some microchips that needed a full progression from 1k up to eliminate them.

-

04-15-2017, 01:28 PM #3Senior Member

- Join Date

- Jan 2017

- Location

- Sarasota/Bradenton Florida

- Posts

- 184

Thanked: 28

Interesting- as I am trying to learn...how can you tell if it was honed with tape or not?

-

The Following User Says Thank You to Sdm84 For This Useful Post:

bobski (04-16-2017)

-

04-15-2017, 02:02 PM #4Senior Member

- Join Date

- Nov 2016

- Location

- Chicago Suburbs

- Posts

- 1,102

Thanked: 292

I have purchased only two razors that were truly shave ready from the factory. One was a Thiers Issard Sheep and Wolf. However, when it came time to refresh it, I found it had originally been honed with tape, so I reset the bevel without tape.

I also got a Rasoir Sabre Le Grelot produced by Ertan Suer that was shave ready from the factory. A friend got one that was not close to being shave ready.

I have purchased several razors from SRD. They had been professionally honed and were shave ready. I do not know what the factory edges would have been like on those blades (Ralf Aust, Boker, and Dovo)

I purchased a couple of Wackers that were minimally shave ready from the factory. All they needed was a quick touch-up on a finishing hone.

I purchased a Jerry Stark custom, expecting it to come shave ready, but it was not even close. Jerry's skills as a blade grinder and scalemaker surpass his skill as a honemeister.

A semi-custom from Brian Brown was minimally shave ready, but required a quick touch-up.

Then there was my Hart Steel quarter hollow "shave ready" blade. It had severe microchips in the blade requiring multiple honing sessions before I finally got a decent shave.

The moral of the story is you either need to have your factory edges professionally honed, or you need to develop the skills to hone them yourself. You cannot count on a factory edge being shave ready, even if they claim it is.

-

The Following User Says Thank You to RayClem For This Useful Post:

tinkersd (04-15-2017)

-

04-15-2017, 07:11 PM #5

+1 for bevel-testing with cherry tomatoes. Works great, no bald spots, and a healthy snack while you hone!

-

04-15-2017, 07:24 PM #6Senior Member

- Join Date

- Aug 2014

- Location

- East Central Illinois

- Posts

- 782

Thanked: 101

Grapes work well also if you don't have any cherry tomatoes!

Slawmeister!

-

04-15-2017, 07:29 PM #7At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

Simply watching the Factory production vids explains why there is so much Hit and Miss when it comes to these edges

The rough bevels are set on a Flat Platen grinder with the spine off the grinder

They are then quickly run across a finisher, spine touching..

If by shear luck those two bevels meets you get a razor that will shave, if they don't well you get a rough tuggy shave.

Experienced stropping can help but that is also hit and miss.

This is why we get so many contradictory stories...

If they were ALL bad or ALL good there would be no mystery here...

-

The Following User Says Thank You to gssixgun For This Useful Post:

MJC (04-15-2017)

-

04-15-2017, 08:14 PM #8At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

Here:

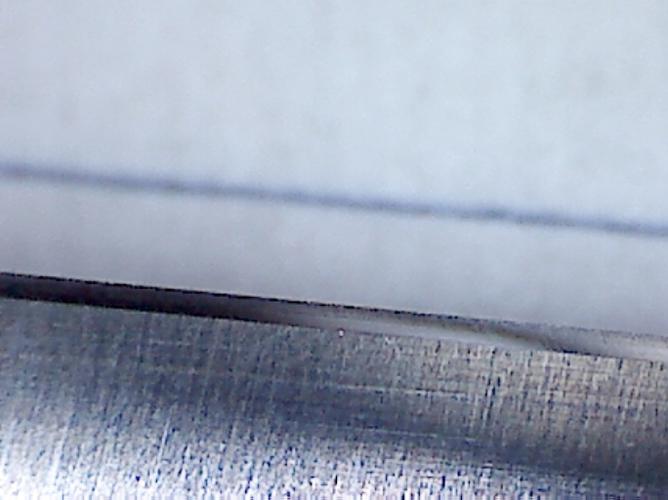

Sealed Boker on the honing bench today

This is the very edge,,, you can clearly see the rough pre-bevel still at the fin where the rest of the bevel is smooth from the finisher used.

Basically this is the exact reverse use of a "Micro-Bevel"

Tape vs No Tape makes zero difference, re-set a solid bevel, sharpen, polish, finish, strop and test shave, why bother thinking about it

-

04-16-2017, 02:06 AM #9Senior Member

- Join Date

- Nov 2013

- Posts

- 758

Thanked: 104

Agree about the tape issue. It matters only if you decide to go with the basic factory bevel, and go with the touch up type honing as a result. It is the only time I don't use tape, that is, if I'm resetting the bevel I use tape, as it's my preference to use it in most cases.. If I have a try at getting the out of the box edge workable with 5 or 10 mins work, I'll stick with what they did in the factory.

Most of the time, it's not worth the mucking around trying to get a factory edge shaving, but if you do come across a razor that's salvageable and you want to see how you fare with it, it's a bit of fun to beat them.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote