Results 1 to 10 of 12

Thread: Problem child needs fixing

-

05-28-2017, 11:47 PM #1

Problem child needs fixing

Problem child needs fixing

This is my problem child. First, it won't stay honed, or sharp. Bought it from John Crowley at The Shaveing Shop. Even he admitted it was very hard to hone. Second, it stains super easy. Glenn (gssixgun) wrote some where he's honed razors that rusted while looking at them. This razor first stained with Coticule slurry on it. I wiped the slurry off and there were spots. Contrast the two pictures. Anyway, I ramble. This really is a thread about honing this razor.

I read with much interest a recent thread dealing with heat tempering and how some blades, if over tempered, can overly harden at the edge. The suggested remedy was to joint the edge several times at the 1k level before progressing on to get down to some good metal.

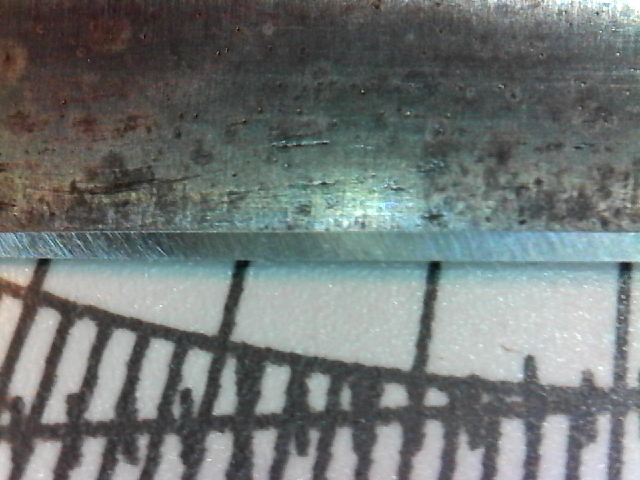

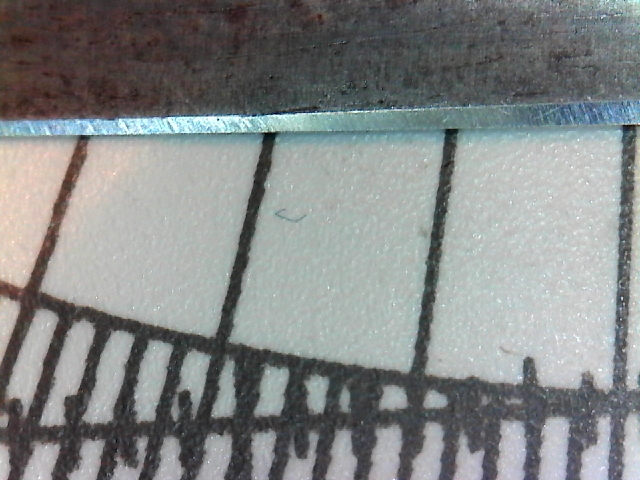

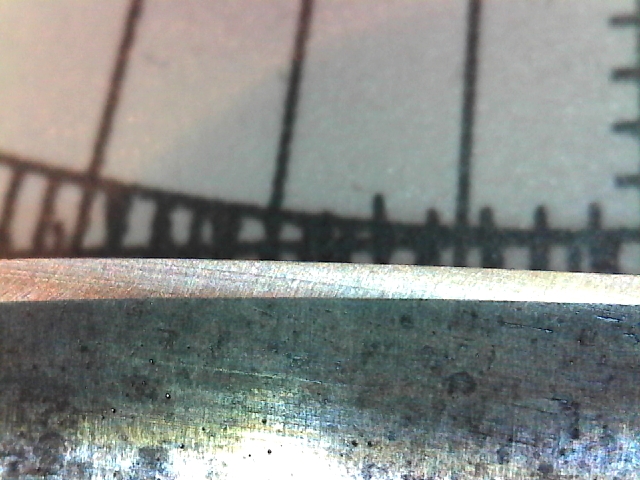

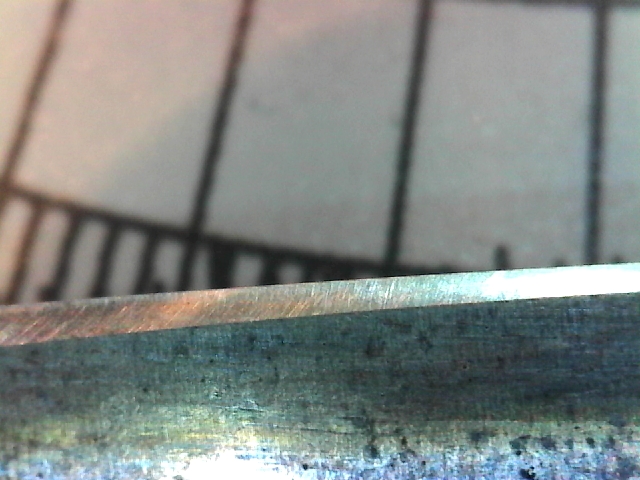

This was the first time I used magnification to aid me at each progression...And I got pictures too. Here's my sequence of progression: Shapton Glass series 1k, 2k, 4k, 8k, Coticule, my new Dan's Whetstone True Hard Arkansas novaculite (featured in another thread), and dozens of strokes on a dry Zulu Grey. Some of the pictures didn't turn out as well as I would have liked, so I don't have pictures at each stage.

Here are the pictures.

Shapton Glass 1k

SG 1k

SG 2k

SG 4k

SG 4I

SG 8k

Arkansas True Hard

Zulu Grey

The ultimate test, and only reliable test, is the shave test. My problem child wasn't a problem today. For what ever reason the edge has been failing after the first or second shave. Hopefully with mounting I was able to get down into some good metal for a lasting edge.Last edited by Longhaultanker; 05-28-2017 at 11:49 PM.

A little advice: Don't impede an 80,000 lbs. 18 wheeler tanker carrying hazardous chemicals.

-

05-29-2017, 05:58 AM #2Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Your edge at 1k looks chippy and possibly not fully set. The toe, is not set, (see photo, SG8K).

You need to spend more time on the 2 and or 4k removing all the deep 1k stria and getting the edge straighter.

At 8k, the stria should be very uniform, honed fully to the edge and the edge should be super straight.

Something is going on with the Ark and Zulu, and look like you are going backwards, or at least not improving the bevel and edge.

Set the bevel on the 1k, fully from heel to toe. Use rolling X strokes to blend the bevel, make sure you are honing to the edge. Watch your pressure, if you use too much you can flex the blade and lift the very edge off the stone.

Re-lap/ re-surface your stone, make sure the edges are beveled or rounded smooth, with lapping strokes parallel to the edge, not perpendicular to the edge.

Ink the edge and do a series of light laps, trying to get the edge as straight as possible, then move up, remove the 1k stria with the 2k and on up. Skip the Naturals for now, strop on Chrome Oxide or CBN, and shave.

There is a lot of pitting on the blade. If you polish the razor with 1 & 2k W&D, you can remove a lot of the micro pitting, being careful of the etch. Buff with Green greased compound and hand polish with a good metal polish, will prevent a lot of the rusting.

-

05-29-2017, 12:49 PM #3

Looks like that blade has some pitting.

I have found that blades with a not fully set bevel tend to shave well once or twice after honing. That will happen time and again until you sort out the bevel.Plus ça change, plus c'est la même chose. Jean-Baptiste Alphonse Karr.

-

05-29-2017, 03:04 PM #4At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,196

- Blog Entries

- 1

Thanked: 13250

Why ???

Regardless of any other things that may or may not be going on, you are using 3 finishers why ???

Here is a simple theory, take it or leave it, when you are getting down to the very edge you only has so much steel there,,, so by stacking finishers your are steadily getting the bevel more and more even BUT you are also weakening that bevel .. It is a point of diminishing returns

-

05-29-2017, 04:48 PM #5Senior Member

- Join Date

- Apr 2008

- Location

- Saint Paul, Minnesota, United States

- Posts

- 2,944

Thanked: 433

I would first check and see how much flex is in the edge (drag the edge across your thumbnail with the edge flat against the nail and apply pressure, you will see the flex) if the edge doesn't flex much or not at all I would tape the spine and use more pressure with the 1k, the bevel doesn't look fully set. Some super hard steel needs an aggressive approach at the bevel setting stage. If you have a CrOx paddle maybe try that after the 8k and strop and test, that will take any finishing stone issues out of the equation.

-

05-29-2017, 05:07 PM #6

I have this razor and honing it also caused me grief - until I applied 4 layers of tape. IMHO the spine is way too thin. It now shaves wonderfully and has held its edge for more than a year.

-

05-29-2017, 10:29 PM #7

What a curse be a dull razor; what a prideful comfort a sharp one

What a curse be a dull razor; what a prideful comfort a sharp one

-

06-02-2017, 01:58 AM #8

I wrote the orignal post on Sunday and I now have had four consecutive shaves using my tamed problem child. I'm supposing the jointing did the trick, getting down to good steel. There is no doubt I still have much to learn about this hobby, such as interpreting magnification images. I'm not much into the various non-shaving tests. If I want to know my razor is shaving sharp, I'm going to shave with it. And if my razor delivers a satisfyingly smooth shave, it must be sharp. This razor will now go back into its regular rotation. It will come up again in about 5 days, then not again for 14 days. We'll see how she does at those intervals, but for now I'm well satisfied.

Glenn, I've thought about your question, seriously. At first I shrugged it off, but it gnawed at me. I suppose technically there is no good answer. For a professional honer looking at getting a job done efficiently, he's looking at the technical issues to complete the task. For me as a hobbiest, who is thrilled with SR shaving, the razors, the stones, strops, brushes, and the accessories, doing my own honing to get a shaving edge, there is only one answer to the question Why. Answer: because I want to. The Shapton stones serve their foundational purpose. But the natural stones I use bring happiness and joy to my heart. I know either of the 3 stones can finish an edge by themselves, but I love handling them all. I love sitting in front of the tv when I'm home stroking a blade on an Arkansas True Hard or Zulu. I'm not looking for technical perfection, I'm looking for emotional satisfaction. I've come far enough now to know I'll probably get a pretty good edge too.

BTW, why are there two threads with the same name with posts split between them?A little advice: Don't impede an 80,000 lbs. 18 wheeler tanker carrying hazardous chemicals.

-

The Following User Says Thank You to Longhaultanker For This Useful Post:

Steel (06-03-2017)

-

06-02-2017, 11:23 PM #9illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

-

The Following User Says Thank You to Utopian For This Useful Post:

PickledNorthern (06-03-2017)

-

06-03-2017, 02:19 AM #10A little advice: Don't impede an 80,000 lbs. 18 wheeler tanker carrying hazardous chemicals.

-

The Following User Says Thank You to Longhaultanker For This Useful Post:

Utopian (06-03-2017)

13Likes

13Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote