Results 21 to 30 of 54

Thread: Taping the spine

-

12-16-2019, 05:29 AM #21

A burr. They happen often when you use a lot of pressure, like when initially setting a bevel or don’t alternate sides when honing, otherwise known as half laps. They sparkle usually and are extremely sharp but not comfortable to shave with. Jointing the edge goes a long way for removing them (after initially setting a bevel draw the edge on the side of your hone as light as you can a couple times, then reset the bevel with light strokes). This will remove any burr that may have formed from initially setting the bevel or fixing a chip.

Most problems guys have with honing is at the bevel setting stage. It’s the foundation. You can polish up your bevels with the rest of your honing progression but if the edge isn’t created at the beginning of the progression you’ll have a hell of time getting there.

-

The Following User Says Thank You to jfk742 For This Useful Post:

STF (12-16-2019)

-

12-16-2019, 06:16 AM #22

I know jointing is a common remedy for that situation but I have never understood the reason when going to the next stone will remove that burr. Just always seemed excessive & like creating more work to me.

Talking 1k bevel sets. 2,4 or 5k as a next stone will do the job ,no jointing needed. If you manage to get a burr at 20k then a run over some horn or bone should be all the jointing needed or some coarse felt or fire hose stropping

If you've really gone too hard at 20k maybe jointing or a lower grit stone is a good idea as the edge may really be too delicate at that point.Last edited by onimaru55; 12-16-2019 at 06:19 AM.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

-

12-16-2019, 11:21 AM #23Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,807

Thanked: 559

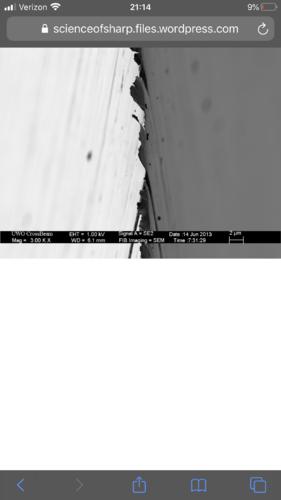

The Science of Sharp blog https://scienceofsharp.com/ provides excellent photomicrographs of edges after various stages and methods of honing/sharpening.

Some of the statements about sharpening razors may be controversial, but the pictures illustrate many of the concepts about sharp edges talked about on SRP.David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

-

12-16-2019, 11:52 AM #24

The whole reason I stay away from diamond hones

Mike

-

12-16-2019, 12:28 PM #25

-

12-16-2019, 02:28 PM #26Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,807

Thanked: 559

That’s a pretty complete starter set with which to learn good honing technique.

Take your time; watch a bunch of good honing videos (Glen Gssixgun has a bunch and he explains what he does very clearly) and check the edge as you go.

STAY FOCUSED, GO SLOW AND GO SMOOTH. I’ve had to go back to the 1K stone more often than I care to admit because I screwed up a single lap on a higher grit stone and messed up the bevel as a result.

Strop a bunch after honing.

Don’t go to the stones unless you really have to. If your razor starts to tug or underperform, try stropping first and/or a few light laps on the barber hone or a pasted strop before you decide to go back to the stones. Many of us hone way more than we need to simply maintain a shave ready edge.David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

The Following User Says Thank You to DZEC For This Useful Post:

STF (12-16-2019)

-

12-16-2019, 02:38 PM #27

The more you hone, the less razor you have.

If you don't care where you are, you are not lost.

-

The Following User Says Thank You to rolodave For This Useful Post:

RezDog (12-22-2019)

-

12-16-2019, 03:40 PM #28

One tip I have learned along the way to reduce tape residue is to make sure no water is present on the blade when you apply a new layer. Buff that spine a bit. That and really peeling off the tape, not pulling it off at a 90 deg angle, if that makes any lick of sense.

-

12-16-2019, 04:05 PM #29Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

“I know jointing is a common remedy for that situation, but I have never understood the reason when going to the next stone will remove that burr. Just always seemed excessive & like creating more work to me.”

Jointing makes a straight edge, much like jointing an edge of a board. It cut off the burr. If you look straight down on the edge after jointing, you may see black spots on the shiny line of the new straight edge.

The black dots are chip that were not fully removed. That says a lot about the edge. A lot depends on the condition and the quality of the steel. If the edge has been worked, shaped or buffed then it is common to get a rough edge and all the roughness will have to be removed to the depth of the deepest chip.

You can hone it all out, or you can just cut it off. It is easier and more efficient, to cut it off straight, than to hope you hone it off evenly. With most all edge tools, jointing is a common practice, to begin sharpening with a straight edge. One can hone the edge straight, either way the same amount of material will need to be removed.

Jointing removes less, as the edge is already straight, and you just need to get the bevels to meet. If the bevels were set, flat and in the correct plane, you only need to get them to meet, a matter of 10-20 laps.

Dragging the edge on a non-abrasive object, tears the burr off and does not cut it off cleanly, creating micro chipping. Yes, we are talking about microns here, but the goal is efficient honing of a straight edge, how ever you get there.

-

12-16-2019, 10:41 PM #30

-

The Following User Says Thank You to onimaru55 For This Useful Post:

rolodave (12-16-2019)

158Likes

158Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote