Results 1 to 6 of 6

Thread: Measuring bevel angle

-

07-03-2020, 11:54 PM #1Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59 Measuring bevel angle

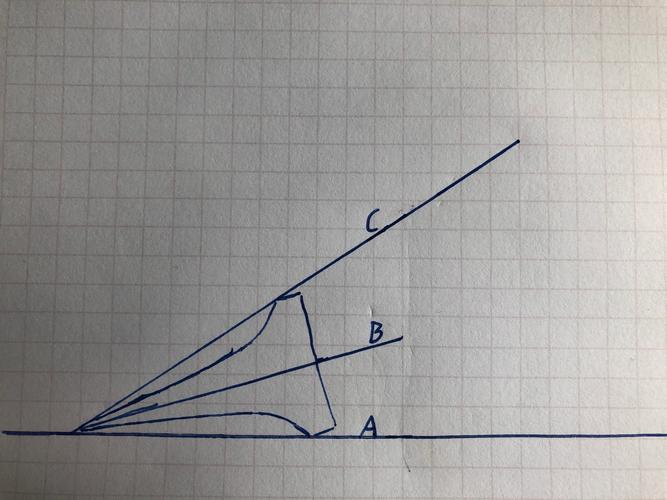

Measuring bevel angle

Okay, this may sound stupid, but given the attached picture how would you measure the honing angle? Never mind my hen scratch not being to scale. Would it be the angle between A-B or between A-C? If this was a knife, I would measure it between A-B. However, I get the feeling that most razor guys use the A-C angle. Here is why I ask. Let's say I have an 8/8 razor that is 1/4" thick. Which is the ballpark for the appropriate ratio of a razor. This would make angle A-B come in at 7.125 degrees, which does not sound right at all. However, that would make angle A-C come in at 14 degrees. This is now in the ballpark for what I hear razors being honed at. Add a layer of tape and we are now right on the money. My guess is that this is just another example of the differences between knife making and razor making, but I would appreciate some verification from you guys.

-

07-04-2020, 12:57 AM #2Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,362

Thanked: 3228

That would be the A-C for the bevel angle on straight razors. I think the sweet spot is a 17 degree bevel angle iirc.

BobLife is a terminal illness in the end

-

07-04-2020, 03:42 AM #3Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Thanks for the confirmation! Five years ago, Bruno told me to keep the width to thickness ratio between 3-1 and 4-1, and to hone it flat. So that is what I've been doing.

-

07-04-2020, 02:02 PM #4

The A-B angle would be the angle of the center line of the blade in reference to the hone on a knife, or the sharpening angle. A-C is usually referred to as the inclusive angle in the knife world. I always think in inclusive, because in the end, that's what the material being cut 'see's'.

As far as the sweet spot, 17° is generally accepted, but I much prefer 15°-16°. Some people even like edges below 15° and others claim that the angle is irrelevant The smaller the angle, the more you are pushing the limits of the steel. Softer steels will not support small bevel angles. I once had a vintage that would not hold a 16° edge, but did fine at 17°.

The smaller the angle, the more you are pushing the limits of the steel. Softer steels will not support small bevel angles. I once had a vintage that would not hold a 16° edge, but did fine at 17°.

-

07-04-2020, 02:27 PM #5

I'm not an expert in geometry or in forging or grinding but as a layman it seems that the pertinent angle is the AC since that is what effects the apex of the edge. The AB and BC angles may not be equal either by accident or by design as is the case with a kamisori if I'm correct. Just an idiots observation for what it's worth.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

07-04-2020, 03:11 PM #6Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

I don't think that either one is right or wrong. It's just a different way of measuring the same thing. For me it caused confusion in the past. As an example, on a hunting knife I would typically put a 20 degree (AB) bevel on it. So when I heard that razors have a 16 degree bevel (AC), the angle that came to my mind was completely wrong. It's just a matter of getting on the same page as the guy you are conversing with.

9Likes

9Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote