Results 1 to 9 of 9

16Likes

16Likes

Thread: Frown

-

08-24-2020, 03:52 PM #1

Frown

Frown

Hi Guys,

I have a razor that I noticed with a loupe has a wider bevel in the center of the blade than at the two ends.

I am having a bit off trouble getting the bevel even the whole length. I'm not saying it has a frown because i don't think it has but I do think it could eventually frown.

Any advice on how to correct the bevel and get it even before I end up with a problem?

I may as well arm myself with some emergency knowledge while I'm on the subject.

If one has a blade with a frown (I don't), how can it be corrected?- - Steve

You never realize what you have until it's gone -- Toilet paper is a good example

-

08-24-2020, 03:58 PM #2Senior Member

- Join Date

- Jun 2013

- Location

- Pompano Beach, FL

- Posts

- 4,044

Thanked: 636

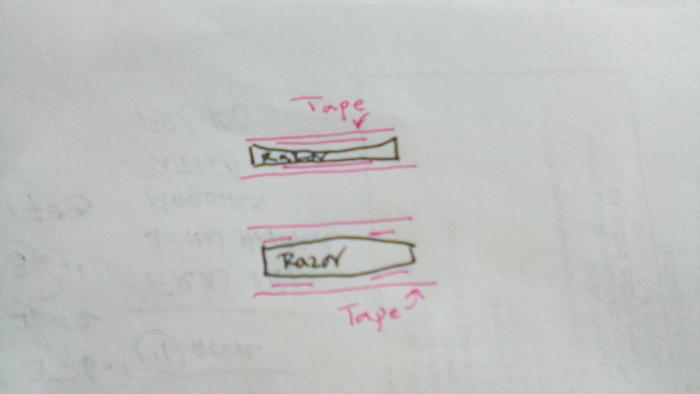

Check both sides of spine with a straight edge. Any low spots get an extra layer of tape to fill in the gaps until spine is straight.

-

The Following User Says Thank You to bouschie For This Useful Post:

STF (08-24-2020)

-

08-24-2020, 04:27 PM #3

Mmmm... photo?

I wouldn't stress an uneven bevel width. It doesn't matter as long as the apex meets.

I would stress a frown. Check with a lined piece of paper under the blade.

Always hone towards a slight smile.

-

The Following User Says Thank You to HungeJ0e For This Useful Post:

STF (08-24-2020)

-

08-24-2020, 11:41 PM #4Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

What does the other side look like? Chances are it is the opposite and the razor has a slight warp, most do.

The width of the bevel does not matter, as long as the edge is straight and honed fully to the edge along the entire length from heel to toe.

Post photos incase there are other issues you are not seeing. Photos usually help in diagnosing problems.

-

08-25-2020, 01:11 AM #5Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Very true. As I grind and hone a razor I find that the bevel is wide and narrow in opposite directions on opposite sides. It can be due to a warp or uneven grinding. It is bound to happen unless you are using a jig or machine to grind the blade. Even with a jig it can happen.

-

08-25-2020, 12:52 PM #6

What they said. A consistent bevel width is not necessary. It is only necessary that you have a flat bevel and both sides meet in a good apex. A narrower bevel in general has some small advantage in honing but not a big deal at all.

A frown is a bit more problematic. There are two approaches: to fix it or just live with it, and I think the majority here will say fix it. The fix is simple enough. Just hone flat, on a fairly wide lapped stone or on lapping film on a verifiably flat plate, until the frown is gone. It is important to not press down in the center of the blade with a finger, especially with a very thinly ground blade that flexes a lot. It is easy enough to check for frown. Stand the razor up on edge on a sheet of paper or stack of paper with no pressure in a dark room. Shine a small, bright light behind it. You can also use the sharpie test to make sure you are getting good contact on both sides along the entire edge. Paint the bevel with a Sharpie, then give it 3 or 4 light laps on your finisher and look for areas where the ink remains. If you have good contact when doing this on a verified flat hone, good to go.

-

The Following User Says Thank You to CrescentCityRazors For This Useful Post:

STF (08-25-2020)

-

08-25-2020, 01:23 PM #7Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

If you do have a frown, (blade width narrower in the middle than the heel and toe), you must reprofile the edge straight, so the blade width is the same from heel to toe.

To do so, you grind the edge straight down, 90 degrees to the stone or diamond plate, usually in a bread knifing sawing motion or high angle grinding, spine off the stone near 90 degree until the blade width is even. You can stroke backwards or forwards, it is not pretty, you are just hogging off material. It does not matter which technique you use, exactly the same amount of material must be removed to get to a straight edge.

It is best to take measurements and mark the blade width at the narrowest point and draw a line with a Sharpie, so the heel and toe match the middle and the blade edge matches the spine. Sneak up on the line as you grind, and stop and take measurements frequently, so you remove the minimum amount of steel. You can buy a pair of plastic calipers for a few dollars, a good investment.

If you just start grinding willy nilly you will remove more steel than you need to, having to correct for removing too much at one point. Take the time to measure and draw straight guideline. If the spine is curved, it probably had a smile to begin with.

You also should carefully examine the razor to identify, if there is an issue that caused the frown, a misshaped heel or high stabilizer, heavy straight stroke honing or a stone that is not flat are common causes. Then repair the razor and pay attention to not repeat the same error that caused the issue.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

STF (08-25-2020)

-

08-25-2020, 03:14 PM #8

I can't get a photo but the blade is not narrower in the middle or anything like that . I am sure I don't have a frown but worry that I might eventually get one because the bevel is wider in the middle than it is at either end.

Ideally I would prefer a nice smile but a reasonably safe bevel that is not being honed into trouble would be fine for just now.

Breadknifing sounds a bit drastic and I have only just got the hang of honing my own razors so I think baby steps might be the order of the day.Last edited by STF; 08-25-2020 at 03:16 PM.

- - Steve

You never realize what you have until it's gone -- Toilet paper is a good example

-

08-25-2020, 04:01 PM #9

-

The Following User Says Thank You to HungeJ0e For This Useful Post:

STF (08-25-2020)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote