Results 11 to 20 of 25

Thread: Want to get my edges correct.

-

08-28-2020, 09:08 PM #11

I decided not to practice on my best razor anymore, I am practicing with my no name English practice razor now.

I added 1 layer of electric tape and 1 of kapton.

I did only x strokes to try and get the scratch pattern all the same direction.

I did:

20 laps with pressure and check x 4 for 80 strokes.

Jointed lightly on the corner.

5 strokes no pressure and check x 6 for 30 strokes

Jointed lightly on the corner.

5 strokes no pressure and check x 4 for 20 strokes.

I stopped there while I still had some razor left!

I do hope there is a decent improvement because quite honestly I am starting to wonder if honing is for me.

I'm not too worried about any chips because I reckon my thumb nail and anoth 3 or 4 strokes could fix them.

Last edited by STF; 08-28-2020 at 09:13 PM.

- - Steve

You never realize what you have until it's gone -- Toilet paper is a good example

-

08-29-2020, 12:16 AM #12

Just to let you know... Honing takes time to learn. I think i was at it for next to 2 years becore it all clicked. Sure, i could make a shaveable edge after a couple months but the next razor i picked up failed. I still get a fail now and then but I know what to do to correct my mistakes now.

Some say honing is easy. Wrong. Honing and getting it right takes time! Now I only had a few hours to practice on my weekends so it took me longer than others.

Just listen to marty and dont give up. One day something will click and its like a slap in the face. You will say to yourself, "why didnt i see that before. It make sence". That is when it starts to come together. Just keep at it. Learn as you go. Take a break when it gets you down but dont give up.

Killing the edge or jointing is done lightly. Its just enough to take a microscopic amount off the edge. Then it should only take a few laps to bring the edge back. I do this often while honing to be sure im getting the most out of my edge before going to the next stone. Learning on your favorite razor was a wrong move. Glad you realised this before it was too late.It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

STF (08-29-2020)

-

08-29-2020, 01:03 AM #13Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

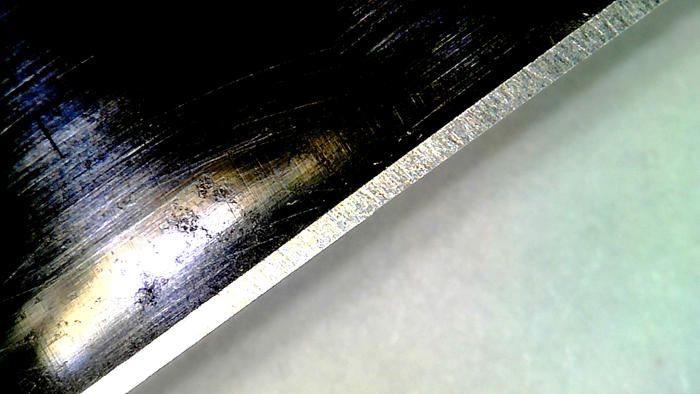

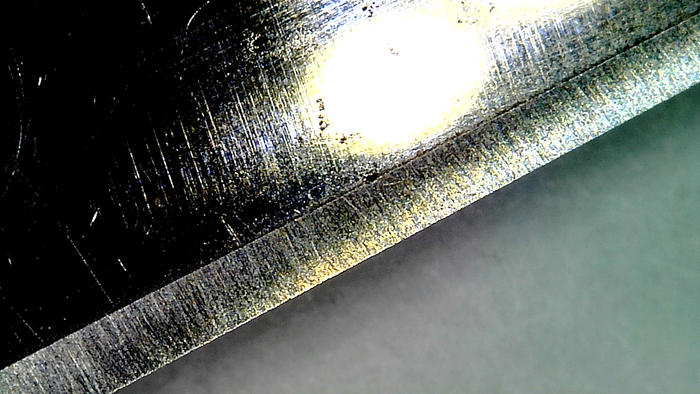

It is difficult to tell much from the last photo because it is not focused on the edge. Focus your micrograph pics on the edge.

Also focus on your honing, you are kind of all over the map, now switching razors again.

So, let’s back up a bit. A fully set bevel is 1. Flat from heel to toe, from the back of the bevel to the edge, a single plane. 2, That plane must be in the correct bevel angle, and 3, the bevels must meet in a straight, smooth, chip free edge. If any of those 3 things are not done fully the bevel is not set. It meets the 3 criteria or not.

None of this, “I'm not too worried about any chips because I reckon my thumb nail and anoth 3 or 4 strokes could fix them”. It meets the 3 criteria or not. If you do not do the things needed to get all three of these criteria to happen, to fully set the bevel then honing is not easy, and will fight your every step, as you are experiencing.

Because in addition to cutting a smooth flat bevel on butter soft steel there are going to be other issues, there are always other issues. The steel is super hard, super soft, pitted, cell rotted, has a warp, a twist, a warp and a twist, hard steel, it chips, the heel need reprofiling, the stabilizer are too big, the edge is smiling, or has a frown, the spine is hone worn and the angle is too shallow, the spine is too thick and the angle is too wide, or any of a multitude of issues, like stone issues and on.

Minimize the variables, control the things that can be controlled. Make each step as perfect as you can, don't get lazy, it will bite you.

The first goal is to grind the bevels flat, I do it with circles on a 1k. Circles cut quickly but create a burr because you are doing multiple laps on one side at a time. When we do multiple strokes on one side, no matter the stroke, circles, half laps, or x strokes it causes a burr. When you flip and do the same on the other side the burr lengthens.

So, grind the bevels flat, then cut off the burr on the stone and do single stroke laps. Alternating single laps are less likely to create a burr, because each time you flip you cut off the micro burr and do not allow the burr to grow.

What I do is, 20 circles with pressure, to get flat. Then check the bevel and edge. If needed do more circles in sets of 10, alternating until flat.

Then do half lap strokes in sets of 10, 5, 2 and 1 alternating after each set. (The Ax Method) a la Alex Gilmore.

Joint, cut off any burr and straighten the edge, then do X strokes with lighter pressure, to reset the edge and lay down a uniform stria pattern. Joint as needed and do X laps, 10-20, until the pattern is uniform and the edge is straight. You are now polishing the bevel on the 1k.

Compare your bevels and edges to the 1k photos in the Second Try at Honing. It takes, what it takes.

When you get the edge straight, joint it and go to the 4k. Do 20 circles to remove the deep 1k stria and check the bevel and edge. Do sets of 10 Ax method laps and check the bevel and edge, stay on the 4k until all the 1k stria is gone.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

STF (08-29-2020)

-

08-29-2020, 03:13 PM #14

I did exactly as you described, thank you for sharing your method.

I don't doubt that you will see where I am still going wrong but I do think things are looking up.

I jointed the edge on the corner of the stone and did the 10 polishing no pressure x strokes and lightly jointed again to be on the safe side and did another 10 no pressure strokes.

The edge does look good with a loupe and does cut stomach hair (my arms are bald).

The image does seem to show small chips, I mention it because I have learned by now that you will find them just a sure as god made little green apples.

I don't understand why I have those small chips as I only did 10 no pressure x strokes since jointing the edge on the stone. I have heard guys here talk about edges that keep crumbling or chipping. Is it possible I have one like that because I can't think for the life of me why I am getting those chips after just 10 no pressure strokes.

- - Steve

- - Steve

You never realize what you have until it's gone -- Toilet paper is a good example

-

08-30-2020, 04:05 PM #15

That edge looks much better. You're improving just in the course of this thread. Don't get discouraged, you'll get it. It takes a while and each razor is different. As Jerry said, one day you'll have the eureka moment. Stria is important but try and remember to focus on the edge. You have gotten good instruction. Maybe try to take a little time to digest it. Don't worry. You'll get it. I admire your determination but cut yourself some slack. You still only have a relatively short time in it.

Are you cleaning your stone often? Chips can come from foreign grit or swarf build up among other things. That's an easy one to eliminate by keeping the stone smooth and clean.

I wouldn't worry quite as much about metal loss from what you have done. You aren't using really low grit stones or doing thousands of laps. It is a danger but I don't think you have removed enough to make that an issue YET.

Keep at it. You're making more improvement than you think. You just have to have patience and be deliberate. I believe in you Steve. Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

The Following User Says Thank You to PaulFLUS For This Useful Post:

STF (08-30-2020)

-

08-30-2020, 06:37 PM #16

Very well said Paul! I could not say it any better.

STF you are almost there! Just play with it a little more. Keep very close track on any changes you do. At this stage in your progression the smallest things count.

-

The Following User Says Thank You to Toroblanco For This Useful Post:

STF (08-30-2020)

-

09-12-2020, 09:03 PM #17

I have had an epiphany!

I honed and honed and honed on my 1k trying to emulate the scratch pattern that Marty showed me but no matter how I tried the edge kept chipping. All be it tiny chips that were only visible under a microscope.

Cresent City razors went into depth on one of my threads (might even be this one) about bevel angles. To be honest most of it went straight over my head and I couldn't see why it mattered so I forgot all about it that complicated nonsense, (my apologies).

Well, I sat and quietly fumed at my little chips. Then a switch flipped in my head and it dawned on me that if my edge was too wide and thin it would be delicate and chip easily. I could only think of one way to tell definitively if that was the case, measure the angle.

Popular opinion seems to suggest that 16 ish degrees is the sweet spot.

I got out my gold dollar that has a big ol spine and was the most likely to have bevel angle issues. I measured the thickness and the width, did the sums and low and behold my bevel angle for my GD is 16.37 degrees. I wanted to protect the spine but electrical tape was too thick and would change the angle more than I wanted so I used just a layer of Kapton, the angle is now 16.62 degrees and I was satisfied.

I set the bevel doing my best to keep the scratch pattern uniform but not like the world was going to stop spinning if it wasn't.

I looked with my loupe and it looked good, I looked under my scope and the tiny chips weren't there. The razor shaved hair so I moved on, 4k and no chips, I jointed the edge a couple of times and bought it back in about half dozen light laps, the loupe looked good and the 1k scratches were gone so I moved on. I jointed it a few more times and bought it back quickly. The loupe was all good, the chips were still not there and the 4k scratches were gone. I moved on to Naniwa 12k ss. I jointed the razor again a couple of times and easily bought it back. The loupe looked good, the scope looked good and the 8k scratches were gone.

I gave it a few of laps on Cro Ox on a leather strop, cleaned it on nylon with 15 laps. 15 laps on cotton twill and 60 on leather. My GD was tree topping like a very sharp thing.

Well I have not been honing long enough to get wicked edges, there are rules you know, so I decided that the hht meant nothing and I should shave.

I have been BBS plenty of times before but today with a GD! What can I say, I don't have a reason to shave until Monday now which is great news for my edge but sad because i like shaving.

I am going to measure the angle on all my razors because think I have learned the secret to a great edge, I wish I had listened earlier when the importance of bevel angles was explained.

The no name made in England that was giving me chip problems will be the first to be measured and I have a feeling that I might just discover why it was chipping.

I added the formula to a spreadsheet so all I do now is enter the thickness and width, the angle is calculated automatically and I can save every razor I measure.

If anyone needs the formula for their spreadsheet just let me know.

I do have one question if I may.

I know how to increase the bevel angle (tape etc), but how would a person decrease it, I assume you don't just wear the spine away until the angle has decreased enough?Last edited by STF; 09-12-2020 at 09:36 PM.

- - Steve

You never realize what you have until it's gone -- Toilet paper is a good example

-

09-12-2020, 10:24 PM #18Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,350

Thanked: 3228

-

The Following User Says Thank You to BobH For This Useful Post:

STF (09-12-2020)

-

09-12-2020, 10:56 PM #19

Congrats! You got one blade figured out.

The next blade may well have different issues. Like Jerry says honing is easy until it isn't.

I don't get all hung up on bevel angles. I do get picky about how thick the blade is before honing.

After polishing most blades will cut arm hair. This is before ever putting the blade on a hone.

These bevels are very thin and take little effort to hone. This approach has served me well. YMMV.

Practice is fun.

Another trick that helps my slightly arthritic hands. Is taping the blade and scales. This gives me much better contro!.

If you don't care where you are, you are not lost.

If you don't care where you are, you are not lost.

-

09-12-2020, 11:26 PM #20

81Likes

81Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote