Results 21 to 30 of 34

-

01-17-2021, 04:33 AM #21

Very likely there is nothing about the spine that really needs fixing. Heel could use a little work, yeah. And you need a bit of the rolling x for that gently smiling edge. You are just honing it flat, for your sharpie test, which is why you have good contact along the central portion of the edge but not heel and toe. That would wirk fine, for a straight edge, but not a smile. Try your sharpie test again, but this time with a finger just barely pressing the edge to the hone near the heel at the beginning of the stroke, and gradually moving the pressure to the toe end with another fingertip as the razor travels along the hone. You will be rocking the pressure between the heel and the toe. Just one stroke, then have a look. Do the other side, have a look. Better? Do a couple more, to get the hang of it. Then try to do the same thing, but without the fingers, just using the one hand on the tang of the razor to roll the x. Be sure to torque the razor slightly so that the honing pressure is properly shared between spine and edge, and not all just on the spine. It's a lot to remember all at once, but it will come natural after a while.

My own personal way is to roll the hone under the razor, not the razor on the hone. But I hone in hand, and when honing in hand, rolling the hone is easy and natural.

Take this or leave it, but I always recommend that beginners hone in hand. It makes regulating pressure a lot easier. Razor and hone are just out there in front of you, as if floating in space, and they come together like two spacecraft docking in the void. Razor and hone find their own alignment. This short circuits many common beginner mistakes. It feels awkward for the first minute or two, then it will be like Ah-HAH! when it comes together for you. I think a lot of new honers try too hard to control the blade with two hands, and it often backfires.

<EDIT> You might also consider painting the spine's bevel as well as the edge bevel, when you do your sharpie test.

-

01-17-2021, 01:47 PM #22

-

01-17-2021, 01:53 PM #23Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

Look through the what are you working on thread. There are razors there with heavy hone wear. The guys that repair that do so by no evening the hone wear, but by hand sanding the flatness, it seems to vanish, but it’s still there, it’s just not apparent. Glen once said something like, the first step in a restoration starts at acquisition. The better the geometry and less wear the more sensible the repair. Razors will show you how they can be repaired but it takes time to see the signs.

It's not what you know, it's who you take fishing!

-

01-17-2021, 02:22 PM #24

When I restore a blade with hone wear it disappears but only through often hours of hand sanding.

Tackling a smiler with hone wear, geometry issues and heel problems is not a project I seek. These blades take lots of time and experience.

As others suggested, start on simple blades and learn from there.

Good luckIf you don't care where you are, you are not lost.

-

01-17-2021, 03:01 PM #25Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

Yes, it suffered some ham fisted honing in its life. Itís from people that are honing with pressure on the toe, for reasons that I do not understand. I think in part itís not just now that people hone without knowing the process. Honing and other hand skills, often have been figure out long before us. Sometimes we have to put a level of trust in those in the loop, choose a mentor and blindly follow their instructions until we understand it. At some point the light comes on and we understand why we are doing it that way.

It's not what you know, it's who you take fishing!

-

01-17-2021, 03:09 PM #26

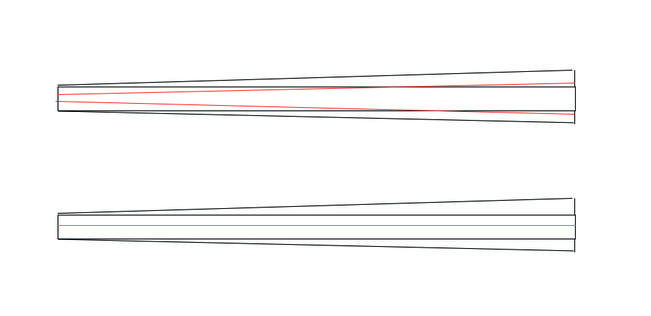

Can someone explain roughly why grinding the spine down (in theory, I'm not going to try it) would ruin the geometry? I made a picture showing what I mean, the way I understand it the only reasonable way to solve the pictured problem would be to even out the spine until its semi-even, otherwise the blade would always sit so severely unevenly on the stone that it would take a high level of skill to hone it into reasonable shape, on both sides, every single time you tried to hone it. The red lines in the picture are roughly what you would get with leaving the blade flat on the hone vs the purple line being if you managed to compensate for it.

I suppose it is actually a correct assumption that it is really hard to get this right and that this razor is essentially garbage to a beginner, but I'm still baffled by the idea that grinding it in theory would mess up geometry.Last edited by rickytimothy; 01-17-2021 at 03:11 PM.

-

01-17-2021, 03:11 PM #27

Definitely will do, when I was given this razor I had no idea in how bad of shape it actually was until Glen showed me how to inspect for certain problems. Believe it or not the person who gave it to me said they shaved with it many times but said it was starting to get dull, despite the fact that the blade was absurdly badly honed and chipped too, I feel bad for that guy's skin.

-

01-17-2021, 03:36 PM #28Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

There is a ratio of ideal spine thickness to blade width that gives the razor the ideal edge. If a well experienced person hones the razor, ideally the spine and the edge wears at the same rate, and the geometry is maintained. Enter a ham fisted person that hones, in this case, with heavy toe pressure. Taking the spine and the edge down on the toe. At this point in theory the edge has worn and the spine has worn, albeit more at the toe than the heel, but the edge angle may be maintained. If tryouts take the spine down all the way to match the spine wear all along, it with throw off the edge angle at the heel. Right now it is most likely that the angles are still ok. Razors of this era were made with pretty delicate geometry and most would not shave or maintain an edge well if that is interrupted.

It's not what you know, it's who you take fishing!

-

01-17-2021, 03:42 PM #29

I am haveing a hard time understanding your issue.

Do you want an exact same bevel on both sides?

-

01-17-2021, 03:48 PM #30

Once you remove steel, you can never put it back.

When a razor is new, it should have a width and spine thickness that combine to give a pretty reasonable bevel angle. As a razor is honed throughout its useful life, steel is removed from the edge, and from the spine. In theory anyway, they are removed proportionally, more or less, and so the bevel angle may change but it won't change much, with proper honing. When you deliberately grind down the spine you are short circuiting the self sustaining geometry.

You will see a lot of razors where the spine is not parallel to the edge and similar defects. You will see the width of the polished bevel surface ending up asymmetrical, wider on one side than the other, or inconsistent, wider at parts of the balde and narrower at others. You will see the spine taking a lot of wear at one end on one side and a lot of wear at the other end of the other side. Believe it or not, this is not an impediment to getting the razor to shave well. As long as you have SOME bevel at all points along the blade on both sides, and they meet in a good, tight apex, the razor will shave just as good as your tools and technique allow. Might not be pretty, but pretty doesn't shave. You can make it look pretty with judicious sanding, but that is a whole nother operation. And you don't thin the spine, only round down the edge of the spine's bevel flat, giving it the appearance of not having been massively honed. Similarly, you can thin the steel on the side and at the point where the edge bevel is wide, and that will make the bevel width more consistent. These are just cosmetic things and very labor intensive. Go for it if you like, but you don't want to grind down the spine, normally. Feel free to experiment, though. There's lots of Dovo Bests out there that are pretty whopperjawed. If you can find some old stock Gold Dollar 66's, you will find many of them are way out of parallel.

The one you got, just hone it with a bit of a rolling x stroke and see what you get. Remember, you are totally totally wasting your time if you don't first get a good bevel set. Advancing through your progression will do no good at all if the bevel is not set.

62Likes

62Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote