Results 1 to 10 of 11

Thread: Any Experience with this Hone?

-

05-01-2008, 03:56 PM #1Senior Member

- Join Date

- Aug 2007

- Location

- Maryland

- Posts

- 112

Thanked: 7 Any Experience with this Hone?

Any Experience with this Hone?

I came across these yesterday in my searches

http://www.leevalley.com/wood/page.a...99&cat=1,43072

Has anyone had any experience with them? They are on sale now and the prices seem to be right on.

-

05-01-2008, 04:49 PM #2Senior Member

- Join Date

- Oct 2007

- Posts

- 1,292

Thanked: 150

More than likely, those are not suitable for use a finishing stone on a razor. "Finishing stone" is a term that is only applicable to one certain application, like knife sharpening, chisel sharpening, razor sharpening. All of those categories have a different definition of "finishing stone."

I think those are around 3k to 6k if I'm not mistaken (DwarvenChef may have one of these exact stones). Get in touch with Old_School for personal support and guidance as to which stones you can actually make use of.

-

05-01-2008, 05:59 PM #3Senior Member

- Join Date

- Aug 2007

- Location

- Maryland

- Posts

- 112

Thanked: 7

Thanks Russel - I'll drop DwarvenChef a line.

I wrote to LeeValley and almost immediately got a response - But it'll be useful to hear from folks who've tried a razor on one of these stones

Thank you for your e-mail. Strictly speaking you can’t assign it a grit number. The grit number refers to the size of the abrasive particles that do the cutting. The smaller the particle, the finer the cut. With an artificial stone you select the abrasive and sort for a specific size, which determines the grit. The forces of nature are not sorting in the same way. The particles tend to be approximately the same size because of the manner in which they were laid down but there is more variation than would be acceptable in an artificial stone. The picture is further complicated because those particles are bonded to each other differently in the artificial and natural stone which effects how much of the abrasive is exposed to the tool to do the sharpening and how quickly worn particles wear away exposing fresh particles.

In practice what we want to know is how it compares to a known standard in this case an artificial stone is a good benchmark. In my highly unscientific opinion, the Honyama stones cut slightly faster than an 8000X artificial stone and leaves an equivalent or slightly better finish. Pretty darn close to an 8000X stone is probably the safest answer.

Last edited by fotoguru; 05-01-2008 at 07:32 PM.

-

05-03-2008, 04:32 AM #4Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Has anyone tried these hones on str8 razors? Let us know please.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

05-05-2008, 05:10 AM #5Senior Member

- Join Date

- Aug 2007

- Location

- Maryland

- Posts

- 112

Thanked: 7

I got mine in the mail yesterday - at some point this week I'll lap it and give it a go. It is quite smooth - I'd say it feels more smooth than my norton 8k, but it's hard to tell. The proof will be in the razor.

-

05-06-2008, 10:29 AM #6Senior Member

- Join Date

- Feb 2008

- Posts

- 766

Thanked: 174

I have. Had it for a few months now.

I have the Honyama. Grade B.... "A" stone shown on the Lee Valley site above.

I had it posted from Canada to the UK some months ago.

I can not speak for the other stones, but suggest they will all be different.

My stone has a perfect working surface, but the base is eneven and needs support to stop it wobbling (Hence the low price) A dish cloth does the job.

I also purchased a natural nagura stone from this place.

www.dick.biz

You need to select English (the Union Jack Flag). Go to Tools then Sharpening, then select natural Japanese stones and curser down to the Natural Nagura.

The Honyama on its own will not do a lot for you. You need the combination with the natural Nagura to make a slurry.

I had to flatten the surface of both of these new stones on arrival. I used a piece of 1000 grit wet and dry...wet... on a glass bed. It's quick and easy. It takes about three seconds to loose the Japanese stamps on the hone surface, so take a photo if this is important to you.

My Honyama in particular is a soft stone and gives off a green slurry. The stone has a very smooth surface. It's 3" wide so very easy to use.

You must emerse the two stones in water for a few minutes before use or the surface of the honyama just soaks in the splashes and drys up to quickly.

The stone cuts best without a slurry. Note...This is the complete reverse of a coticule.

It cuts at about 6000 to 8000 grit and I would say, the same as a coticule. Totally different soft feel, but the same effect.

With a slurry created with the natural nagura stone, the cutting surface becomes a polishing surface. It polishes to a 10,000 grit level. The more you polish, the more the particles break down and the better the polish. Again, the complete reverse of the Coticule which polishes best with no slurry and just water.

I am no expert, but I like to experiment a bit. I find I prefer the coticule with a softer carbon steeled blade and the nagura/honyama with a harder steeled swedish/silver steel/stainless type blade.

They are very similar perhaps the japanese combination gets a better polish and this helps soften the harder steeled blade.

But to be honest, a few laps on a pasted strop achieves the same effect.

I'm sure if you pay megabucks for a natural Japanese hone you will get a really high grit hone that is superb.

I'm usually satisfied with the edge that a coticule will give. Softening or extra sharpening can be done easily with different paste on linen or leather on flat bed or hanging strops, etc.etc.

It's my belief that its the creation of the furry clingy edge that is the key to a good razor edge. The coticule does this superbly and will in my opinion never be bettered.

All the other higher grit stones and pastes and fancy glass hones just polish.

If you have no furry edge to start, the rest have nothing to polish. Its the same reason why the Norton 8K is so successful. In Europe however I was brought up with the coticule so prefer it. The man in japan will I am sure prefer a natural local clay stone.

Which is best. I think this has more to do with who is using the stones than the stones themselves.

Still I find my japanese combination, great value for money and good fun and effective to use.

I'll put some photo's up a little later. Hope this helps.

-

05-06-2008, 12:29 PM #7Senior Member

- Join Date

- Feb 2008

- Posts

- 766

Thanked: 174

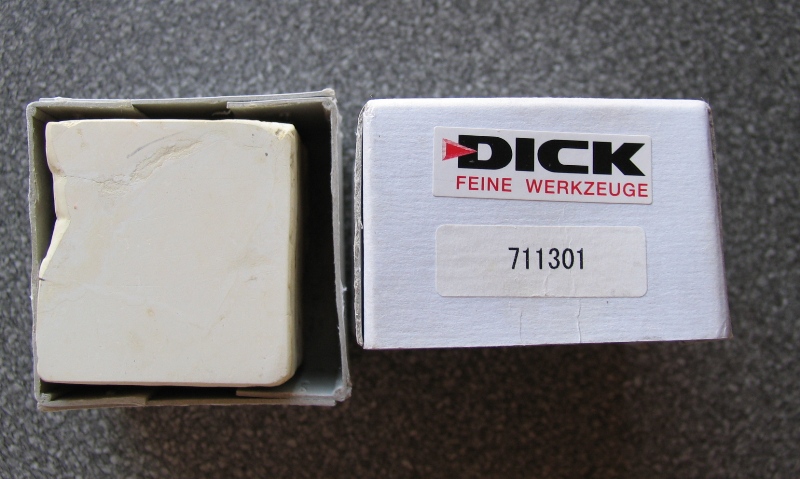

Photo's as promised:

Honyama... dry in box

Nagura....dry in box-the nicks in the side are where impurities have been removed

Honyama...wet with nagura slurry and ready to polish

Coticule...wet with cotigura slurry and ready to cut

Last edited by English; 05-06-2008 at 03:55 PM. Reason: bigger pics.

-

05-06-2008, 11:13 PM #8Senior Member

- Join Date

- Oct 2007

- Posts

- 1,292

Thanked: 150

Great to hear that these are usable stones! The stone I was thinking of when I said the grit might be 6k was from Hida Tool, my mistake.

That website doesn't specify the grit rating on the nagura, but I wouldn't be surprised if it were aiding in the polishing effect that you describe when using a slurry, since the same stone would be used for even finer polishing stones.

It is commonly said that Japanese stones become finer and finer with use because the grit particles break down as they are exposed. While many other stones have grit particles that are hard enough to keep their size and shape as they are used.

-

05-09-2008, 03:50 PM #9Senior Member

- Join Date

- Aug 2007

- Location

- Maryland

- Posts

- 112

Thanked: 7

English - Thanks for your in depth response. I lapped my stone up and have tried it both with and without slurry (I used a small piece of chinese 12k as a slurry stone). As you said in your reply - these are natural stones and they're all different. Mine is certainly not a finishing stone for a razor. Right off this stone, razors will pass the HHT, but a shave right off this stone is not the most comfortable shave I've had. It will have it's place among my hones, but is not the last step in the process.

-

05-16-2008, 06:13 AM #10

My experience is the same. I feel 6k is about right.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote