Results 11 to 20 of 34

Thread: Can someone help a lost honer?

-

07-24-2008, 08:17 PM #11

It doesn't look like anyone has yet questioned whether or not you have an appropriate and necessary bevel on the edge of that razor yet. Based on your description and how you've concentrated on how the bevel faces on each side of your blade look, I suspect your bevel is not "set". You can have the most glorious looking bevel faces on each side of the blade; they can look perfect. BUT.....if the the two faces of the bevel don't meet along the length of the blade (the "EDGE"), then all is for naught.

I've been sharpening some wood chisels for someone recently (Go figure, Shapton ceramic stones work superbly for this ) and your post has motivated me enough to go home tonight and take magnified pictures that I think will visually illustrate what we're talking about. The chisel edge is a great example to use since the bevel angle at 25 degrees rather than approx 17 for a razor and since these are previously unhoned chisels. Keep watch on this post. I won't be able to add to this with pictures until later tonight.

) and your post has motivated me enough to go home tonight and take magnified pictures that I think will visually illustrate what we're talking about. The chisel edge is a great example to use since the bevel angle at 25 degrees rather than approx 17 for a razor and since these are previously unhoned chisels. Keep watch on this post. I won't be able to add to this with pictures until later tonight.

Chris L"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

The Following User Says Thank You to ChrisL For This Useful Post:

McShaverson (07-25-2008)

-

07-24-2008, 09:00 PM #12Senior Member

- Join Date

- Jul 2008

- Posts

- 123

Thanked: 5

WOW! These are some incredible replies! Thanks guys. Ummmmm ok...... lets see.... I think that my problem might be that my hair is too fine because I have SUPER fine, but thick hair. I am however very interested to try newspaper and a metal polisher. One question though. I use a stropping technique on the news paper right? I can't wait to see the pictures to see if what i'm seeing is a smooth face rather than a set bevel... hmm.... I'm not sure. Either way thanks for the speedy and informative replies

Thanks,

Kevin

-

07-24-2008, 10:43 PM #13

-

The Following User Says Thank You to Sticky For This Useful Post:

McShaverson (07-25-2008)

-

07-25-2008, 03:47 AM #14

Bevel illustration using a wood chisel!

Bevel illustration using a wood chisel!

As promised, here are some pictures using a wood chisel to illustrate to newer guys what we mean when we say a bevel must be "set". Others have already done a great job at discussing the importance of a proper bevel; most recently, one of my favorites, David Polan's (HeavyDutySG135 I believe) multi-segment video tutorial on honing.

But, different things "click" with different people and this was fresh on my mind recently in honing chisels for someone so maybe this will help.

Bottom line, when we hone razors, we're removing and then polishing metal on the surfaces or faces of both bevels (a wood chisel, unless it's back beveled only has one bevel and a flat bottom ("face"). We want both bevels to be similar in appearance (it wouldn't be good to hone one side to 1000 grit and the other to 16000 grit) in relation to the scratch pattern of the grits used when honing and then polishing, but it doesn't matter a lick if one bevel's width when viewed is thinner or uneven from another because......................the faces of the bevels don't cut whiskers, the EDGE does. What is the edge? The two bevels MEETING in one line the entire length of the razor blade. Quite simply then, this is when a bevel is "SET". If the bevels don't meet, or if they only meet sporadically across the entire length, even thinking of polishing the edge at that point is useless. It's difficult even with magnification to view the edge of a razor head on to determine across its entire length whether the bevels are meeting exactly as they need to. It's easy to view the faces of the bevels even without magnification, but again, it's about the edge.

Ok, Ok, enough already, here's what I mean:

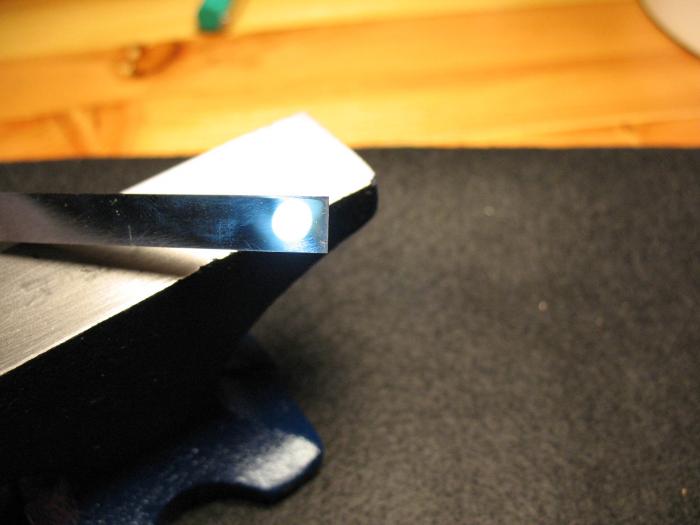

This first pic shows the one bevel of a wood chisel. You see 3 different stripes. The left most coarsest stripe is that way because it doesn't have to be any more polished; it doesn't do any cutting. The middle stripe is the 25 degree angle of the bevel polished to a mirror smoothness. It didn't need to be nearly that far up the bevel either since it doesn't do any cutting. Finally the white stripe at the tip is the micro-bevel (23 degrees). It's also larger than it needs to be but it's good for the photo. It's also mirror smooth. Looking at the FACE of this bevel then, it's looking pretty impressive.

The flat bottom (the "face") of the chisel. It's mirror smooth. I wish the picture was a bit better but you get the idea. Looking at the surface of this chisel face, how could we get better than mirror polished?

So we have two faces (chisel face and bevel face) that look just great. They look like this chisel is ready to part woodgrain like butter.

This next picture tells it all and brings it all together...........................

There it is!!!! Does the bevel and the face (bottom) of this chisel meet to form an edge? Not even close!! You can even see the striated grind marks from squaring up this badly nicked and abused chisel on my grinder prior to any honing! Would this chisel cut anything? No. Now, here's what brings this illustration around to our razor purposes. On this chisel, IF I would simply continue to work back and forth on higher grit stones (4000, 8000, 16000), essentially polishing the bevel and the face, it would probably take days to get an edge. This chisel edge needs serious metal removal that only a coarse grit stone will provide.

Us SRP members that have been around awhile and hone our own razors can't count the number of times we read: "I started honing my first or second razor and I've spent hours and I can't get this *&$##$%#$#^%^ thing sharp!!!!"

Gotta set the bevel. I think it was Glen (GSSixxgun) who said it so perfectly recently; it was something like "sharpness is established at the bevel setting stage and not the polishing stage". The honing forums are plentiful with info on how to test for bevel setting success.

I hope this helps.

Chris L

P.S. the bottom pic is just a different shot of the bevel of the chisel. I meant to delete it but can't figure out how during editing. Oh well, it does show mirror smoothness.Last edited by ChrisL; 07-25-2008 at 09:51 PM.

"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

The Following User Says Thank You to ChrisL For This Useful Post:

McShaverson (07-25-2008)

-

07-25-2008, 03:53 AM #15Senior Member

- Join Date

- Oct 2007

- Posts

- 1,292

Thanked: 150

I just figured it was an issue with the 8k limitation because the edge is shaving, just not well and in my experience a razor that has an improperly set bevel will feel more like a saw than a razor. But everyone's method and results vary so it wouldn't hurt to be extra mindful of how much time you spend on the lower grits.

Otherwise I'd say your on the road to success, congrats!

-

The Following User Says Thank You to Russel Baldridge For This Useful Post:

McShaverson (07-25-2008)

-

07-25-2008, 05:28 AM #16Senior Member

- Join Date

- Jul 2008

- Posts

- 123

Thanked: 5

Wow, ok thanks for the super post Chrisl. I do belive my problem lies in my bevel establishment and here is the reason why.

I started honing my second razor after I had purchased a better microscope only to see that, on my other razor, the edge wasn't as "smooth" as I had seen in my first microscope. So, I honed the secnond razor until the edge was perfectly even on the 4k side and then moved on to the 8k side for the polish. Once the edge looked perfect I tried the hht again with no avail, but remembering that my hair is very fine I decided to go ahead and give it a few rounds on my strop (no paste) and try again and Vwala it passed! So, what i believe is happening here is that the 8k side of my hone isn't provideing a finished enough edge to slice my hair.....but..... on the other hand, it does cut my arm and leg hair quite nicely (before stropping)........ Anyway, what I plan to do is re-hone my first razor and the strop it with newspaper and paste and then try the hht again to see the results. Also, when my facial hair grows back, I will reshave my face with my second razor to judge the smoothness compared to my first razor. Stay tuned in for the update.

Thanks A LOT,

Kevin

-

07-25-2008, 02:19 PM #17At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

Great illustration of of the bevel Chris, as they say a picture is worth a thousand words, and you just spoke volumes....

I think part of the problem is that with razors is that the flat spot that is soooo visable in your pictures of the chisel, is much, much, thinner to start with on a razor, so people dont' realize that it is still there, but it is.... That why I always try and stress the importance of setting that bevel first, honing a razor is almost easy, once that first stage is done....

Great Job Chris

-

The Following User Says Thank You to gssixgun For This Useful Post:

McShaverson (07-25-2008)

-

07-25-2008, 03:19 PM #18

Thanks Glen.

Exactly right in what you said. I used the chisel to illustrate for the very reason that the "edge" or what should be the edge on the chisel clearly is not an edge (even though the bevels look great and one could assume that they're meeting as they should to form a cutting edge). Unlike this chisel, who can see a razor edge and whether the two razor bevels are forming along the entire length of a razor to form an edge? I know MY eyes aren't that good! It's not even easy for me to inspect the EDGE using my good stereo microscope. Does anyone have an electron microscope they'd want to sell me really cheap?

Chris L"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

The Following User Says Thank You to ChrisL For This Useful Post:

McShaverson (07-25-2008)

-

07-25-2008, 06:20 PM #19

Check out my videos here: http://straightrazorpalace.com/video...eo-series.html

Specifically the ones regarding setting the bevel before polishing. If your razor does not feel sharp then it is not sharp regardless of what the sides of the bevel look like. A side view is not an indication of sharpness because that does not show the thickness of the edge.

-

The Following 2 Users Say Thank You to heavydutysg135 For This Useful Post:

ChrisL (07-25-2008), McShaverson (07-25-2008)

-

07-25-2008, 06:47 PM #20Senior Member

- Join Date

- Jul 2008

- Posts

- 123

Thanked: 5

UREAKA! I've done it!

I sat down with a piece of balsa wood and some MAAS polisher and stropped the razor 100 laps, pulled a hair from my head, ran it across the blade, and "Ting", my full hollow ground henckels twin straight sang to me like an angle from the heavens!

I sat down with a piece of balsa wood and some MAAS polisher and stropped the razor 100 laps, pulled a hair from my head, ran it across the blade, and "Ting", my full hollow ground henckels twin straight sang to me like an angle from the heavens!

However, I'm still going to watch all of the honing video's and keep in mind that shiny sides doen't mean a set bevel, but for now I will rejoice that I have a shave ready razor that I have, whether by dumb luck or pure skill , honed myself

, honed myself  I thank you guys for the TREMENDOUS amount of help that you have given me and wish you all many super sharp hones

I thank you guys for the TREMENDOUS amount of help that you have given me and wish you all many super sharp hones

Thank you,

Kevin

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote