Results 1 to 10 of 11

Thread: Spyderco Medium to set bevel?

-

08-17-2008, 02:08 PM #1Junior Member

- Join Date

- Apr 2008

- Posts

- 11

Thanked: 0 Spyderco Medium to set bevel?

Spyderco Medium to set bevel?

Hey guys, I have the spyder co medium, fine, and ultra-fine stones. They are roughly equivalent to 4000, 8000, 12000 grit stones. I'm practicing on a cheap razor and cannot seem to get an even honed edge going. It seems like the middle is more honed than the edges, and the bevel is not consistent. Is the sypderco medium sufficient to set a bevel, or do I need another stone? If i need another, what can ya'll recommend?

Thanks a bunch, still learning this art!

-

08-17-2008, 03:23 PM #2Senior Member

- Join Date

- Oct 2007

- Posts

- 1,292

Thanked: 150

A good rule of thumb: if you are not absolutely amazed at how sharp the cutting edge is, the bevel is not set, keep honing until it stops getting sharper.

You could try honing on 1k grit sandpaper (hardware stores usually have it). You just soak the paper for a few minutes, lay it on a flat firm surface (glass, another hone, etc), and hone as you would normally.

That'll get things moving a little faster without the need to buy another stone.

Though, a 1k grit hone is not very expensive: NIB KING JAPANESE WHETSTONE KNIFE SHARPENER (1000 GRIT) - eBay (item 120294327604 end time Aug-20-08 17:06:57 PDT)

Good luck, let us know how things go as you continue to work on it.

-

08-17-2008, 04:55 PM #3

I have the Spyderco M, F and UF. That medium is pretty slow unless you put some fair pressure on the blade, IMHO.

Sandpaper will hog that steel off in no time though, and the spyderco's can clean it up and finish it off.

Edit: I like the DMT 1200 and 8K hones for restores and bevel setting more than sandpaper, even though they are a little bit slower.

-

08-17-2008, 07:30 PM #4

Sounds like the razor has a smile so if you are just laying the razor on the hone and doing a pass, only the centre of the blade edge will get honed. There are threads on here that explain how to do a rolling X pattern which is what I suspect you will need to do. With the hones you have, you have no problem maintaining an edge on a razor.

PuFF

-

08-18-2008, 12:28 PM #5Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

I agree with the above, all of them!

From your post it sounds like you expect the width of the bevel to be the same for the full length of the edge. That will not happen with a razor that has a "smile" shape to the edge. What is important is that all of the edge comes in contact with the hone during some part of the stroke. That is accomplished by using an rolling X pattern honing stroke.

My avatar shows the X pattern, but the rolling movement has not been shown with a graphic or video yet.

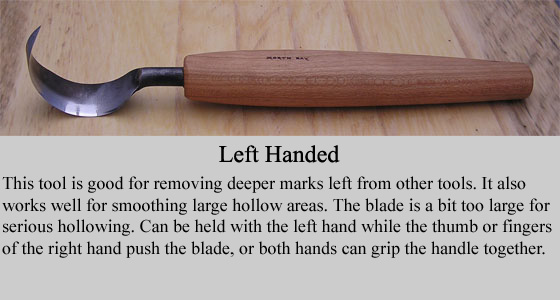

Imagine the stroke necessary to sharpen a wood carvers bent blade

that looks like this......

You use a similar type of stroke but not as extreme a lift on the handles. The key thing to watch is the water in front of the blade. The puddle of water should move from the heel to the toe of the blade as you make the X pattern.

I guess I will have to get someone over here and make a video of that honing stroke. A lot of us have tried to describe it in written form but a video would be much better.

Does anyone know if the video series by Heavyduty demonstrates the rolling X? I cannot recall.

Hope this helps, Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

08-18-2008, 01:40 PM #6Senior Member

- Join Date

- Oct 2007

- Posts

- 1,292

Thanked: 150

I've got a low tech photo guide

http://straightrazorpalace.com/advan...rolling-x.html

I think the rolling x is in David's video, but I haven't watched them all so I don't know for sure.

They're definitely worth watching if you're wanting hone straight razors correctly. http://straightrazorpalace.com/video...eo-series.htmlLast edited by Russel Baldridge; 08-18-2008 at 01:44 PM.

-

08-18-2008, 02:51 PM #7Junior Member

- Join Date

- Apr 2008

- Posts

- 11

Thanked: 0

I have not done the "rolling" x manuever, only the flat x stroke. Also, I do not use water with my spyderco hones, I use em dry. Might it help to try to use them wet? The razor is sharp and cuts arm hairs, but does have a smile in it. I was using a microscope to notice the progress made.

-

08-18-2008, 02:58 PM #8Senior Member

- Join Date

- Oct 2007

- Posts

- 1,292

Thanked: 150

The only thing that matters is that every part of the cutting edge contacts the hone at some point in the stroke. I've had blades with a little bit of smile and the regular x stroke was perfectly fine.

Water can make things a little smoother, but it will not set the bevel any faster. The blade still needs contact, along it's full length, with a coarse to medium honing surface for the bevel to be set properly.

If parts of the blade are cutting arn hairs, then the bevel is on it's way to being completely set, it just needs to cut the hair the same way at every point on the edge before you move on to finer grits.Last edited by Russel Baldridge; 08-18-2008 at 03:59 PM.

-

08-18-2008, 03:52 PM #9

Have you checked your hones for flatness? Lapped?

-

08-21-2008, 04:20 PM #10Junior Member

- Join Date

- Apr 2008

- Posts

- 11

Thanked: 0

How would you go about checking for flatness? The spyderco hones aren't meant to be lapped...I believe if they aren't flat, you return them back to the company and they flatten them for you. On inspection, they seem flat.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote