Results 1 to 10 of 21

Thread: Swaty mystery solved ?

-

11-19-2008, 04:36 AM #1

Swaty mystery solved ?

Swaty mystery solved ?

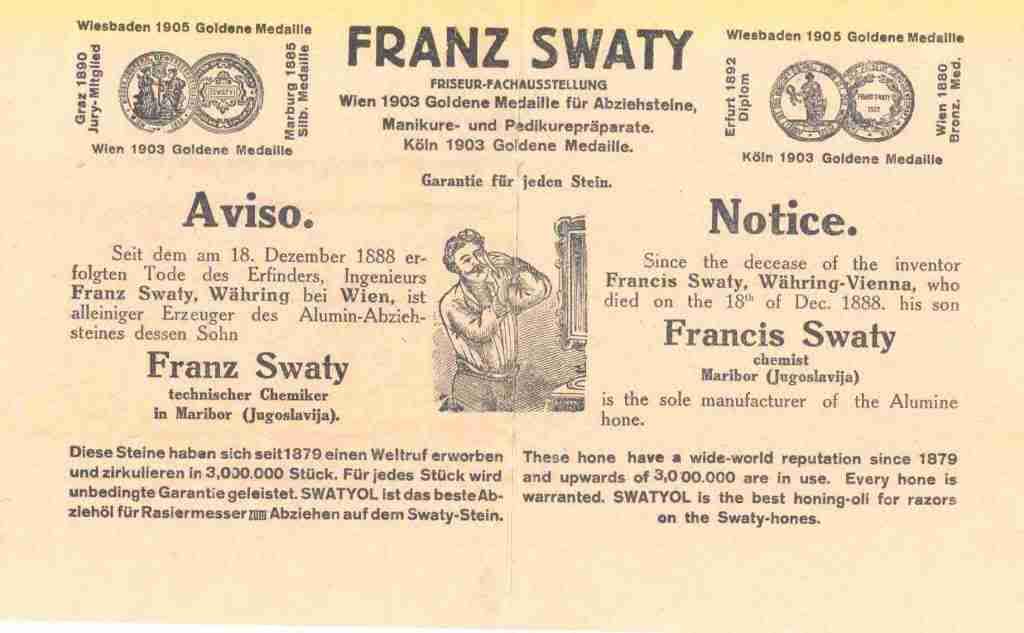

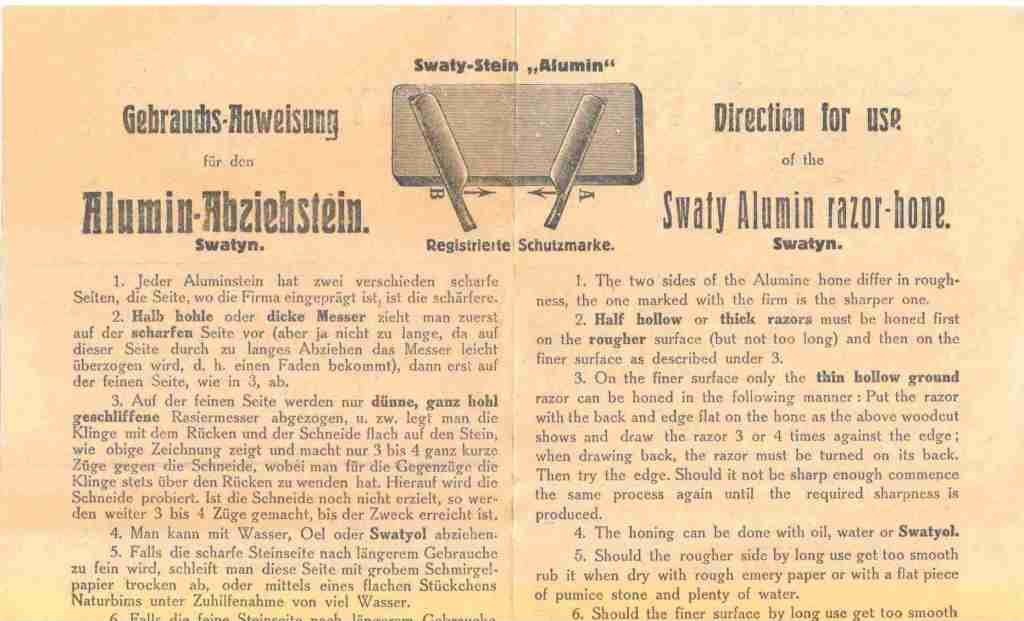

I picked up a mint in the box NOS long Swaty with instructions. There have been threads in the past with folks debating whether the two sides of the Swaty were the same or if one side was rougher then the other. Here are photos of the instructions that say that the side with the factory name embossed is for honing and the other side is for finishing.

This particular hone has the logo engraved into the material. All others I have seen have raised letters be they long or short hones. Down page the last photo shows an ink stamp on the hone that has the same graphic of the blades on the hone with directional arrows that is in the instruction sheet. Also the "Swaty Alumin" name. So apparently aluminum oxide is the abrasive in the Swaty. This is so cool being that it is pristine I may just keep it as is.

Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

The Following 2 Users Say Thank You to JimmyHAD For This Useful Post:

Ben325e (11-19-2008), FloorPizza (11-20-2008)

-

11-19-2008, 05:01 AM #2

Very cool, Jimmy. And, very bizarre. The Swaty 3 lines of text hone I had exhibited no discernible difference in smoothness nor in cutting ability whatsoever from the top versus the bottom side. None. Also, mine prior to lapping had a micro thin chip on one of the sides that revealed the unglazed portion under the surface and the grit on that hone was homogenous throughout. Strange. Granted there were different Swaty versions so maybe that was it? Does your new swaty look like a two grit hone?

Chris L"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

11-19-2008, 05:06 AM #3

"the side with the firm imprinted is the sharper one"

I take this to mean that the side with the name embossed into it is the finishing side. The back of the hone would be the side that you would want to use first. Is this what you meant? The side with the name is the finishing side, no?

-

11-19-2008, 05:10 AM #4

-

11-19-2008, 05:12 AM #5

Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

11-19-2008, 06:34 AM #6illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

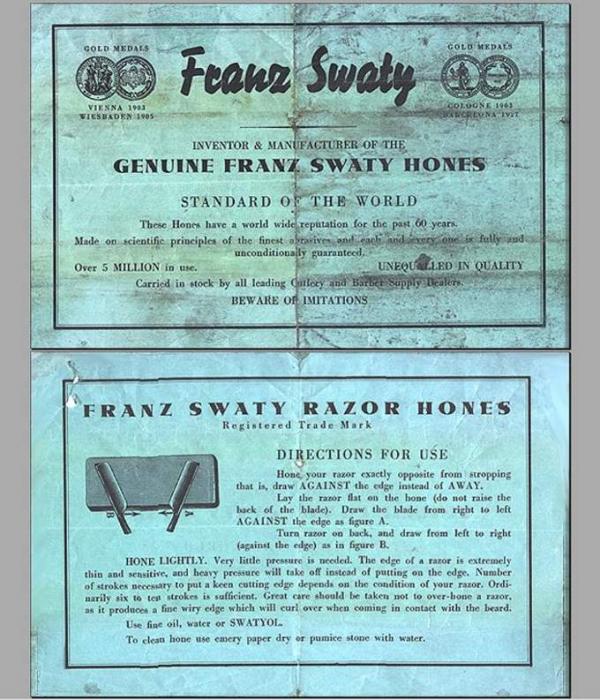

I think those instructions are only for the Swaty Alumin, not any of the other Swatys.

-

The Following User Says Thank You to Utopian For This Useful Post:

JimmyHAD (11-19-2008)

-

11-19-2008, 11:29 AM #7

Here's the instructions for another type ( not Alumin ?) of Swaty found on the Web :

-

-

11-19-2008, 03:52 PM #8

That is why I put a question mark in the title of my post when I said 'mystery solved'

Sure enough, come to find out that the Alumin is a different model. Or is it ? Anyone know what the abrasive is in the 'regular' Swaty ?

Sure enough, come to find out that the Alumin is a different model. Or is it ? Anyone know what the abrasive is in the 'regular' Swaty ?

Tell you one thing I know for sure and that is the 3 I have come across as well as a few other barber hones are far from being flat either the long way or across.

I notice that the instructions I put up talk about the father passing away in 1888 and his namesake taking over production. Perhaps this one dates to the turn of the century ? The instructions that McKie posted say that the Swaty had been around for 60 years. No mention of the father or the son. The son may have been gone by then as well.

My curiosity is compelling me to give the Alumin a try. If I do I would have a heck of a lapping job ahead of me. I am going to try putting it on a flat surface with some weight on it first to see if I can get some of the camber out of it. If I ever do hone with it I will let y'all know my impressions of one side as opposed to the other.Be careful how you treat people on your way up, you may meet them again on your way back down.

-

11-19-2008, 04:49 PM #9

Thanks for sharing Jimmy. I believe there is a similar (or maybe the same) document posted in the help files section. As mentioned above, there were a few different Swaty's produced, and it is not clear which directions go to which hones. On my Swaty, I am pretty sure both sides are the same grit, but it's hard to tell.

-

11-19-2008, 05:20 PM #10

It could also be possible that they are not refering to a difference in grit between the two sides but a difference in ability to remove metal. Thus the reccomendation of rubbing emory paper on the one side to make it rough again.

2Likes

2Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote