Results 1 to 8 of 8

-

05-16-2009, 01:00 AM #1Stubble Slayer

- Join Date

- Jan 2009

- Location

- Alexandria, VA

- Posts

- 708

Thanked: 171 Great lapping sandpaper for heavy duty work

Great lapping sandpaper for heavy duty work

So I just got in an escher, and it had a gouge in it about 3/32" deep, maybe a touch more (see pics). I started going at it with the D8C per usual, but it was sllooww going. Also, I didn't want to keep a constant stream of water on it as I usual do, for fear of completely wiping out the label before I've even thoroughly read and enjoyed it.

In the past, I've had terrible luck with norton and 3m w/d sand papers wearing out really quickly when lapping and therefore making lapping take forever. I've tried 320 grit and 600 grit for the w/d for lapping. This is why I love the D8C, because it's fast.

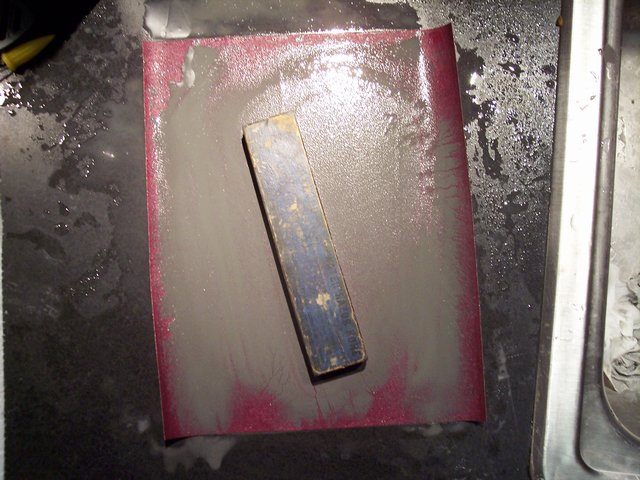

Enter 3M "sandblaster" 120 grit sandpaper. Bought it at advanced auto for $5 per pack of 3 (I got the 9x11 sheets but they make 3.5x9 or something too). Wow, this is good stuff. I took the entire gouge out of the escher (vintage thuringian) with ONE sheet in under a half an hour. It was literally just pouring slurry out at a rate that put the D8C to shame. This paper says it lasts 3x longer and resists clogging, and I was very skeptical, but I have to say that I'm impressed. I didn't have to rinse much at all, it really does just keep trucking and not clogging up.

Now, to be fair, I've not tried any regular 120 grit w/d paper for lapping, so for all I know this is the norm. Also, these vintage thuringians are quite soft from what I can tell and lap quickly anyway. But still, I'm very impressed with this paper. If I had tried to do this job with the D8C, it would have taken AT LEAST 2 hours. Probably much longer.

Here are some pics of the progress. I did some finish work on the D8C just to smooth things out.

-

The Following User Says Thank You to pjrage For This Useful Post:

Arg (05-16-2009)

-

05-16-2009, 01:19 AM #2

I was watching that auction... I got the sweats towards the last minute, but I resisted the bid.

Looks like you made out pretty darn well there. Thanks for the heads up about the sandpaper.

-

05-16-2009, 05:13 PM #3

When you say 'sandpaper' do you mean what we Brits call 'Wet and Dry'? Sandpaper would disolve after 2 minutes, but wet and dry is designed to be used wet. For comparison. sand paper is normal sand coloured sand paper and wet and dry is alway black in colour here in the UK.

-

05-16-2009, 05:28 PM #4Beard growth challenged

- Join Date

- Feb 2009

- Location

- Berlin

- Posts

- 1,928

Thanked: 402

Great stuff!

Personally I would not have taken off such a lot from that hone.

-

05-16-2009, 10:44 PM #5illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,551

- Blog Entries

- 1

Thanked: 3795

It's a little too late now, but you really did not need to remove all of that precious good stuff. Once you had the rest of the stone flat and smooth, you could have left the gouge alone. It would not have interfered with honing at all. It might have taken you many many years to get down to the level that you're at now.

-

The Following User Says Thank You to Utopian For This Useful Post:

JeffR (05-17-2009)

-

05-16-2009, 11:19 PM #6Stubble Slayer

- Join Date

- Jan 2009

- Location

- Alexandria, VA

- Posts

- 708

Thanked: 171

Yeah I figured I didn't have to take it down, but I want it to look pretty

At 3/4" thick now, there is still plenty of stone left. This stone will be lost or broken by someone long before it wears out.

Hugo, I didn't notice if the sandpaper explicitly said it was wet/dry, but it's definitely waterproof. Even more so than regular w/d. It like doesn't get saturated or clogged. It's coated in something I think. Really amazing stuff. It's marketed for autobody work, so it's intended to be used on steel, and probably wet-sanded with. I agree that most w/d paper I've seen is black or grey, but this stuff is pink/purple

-

05-17-2009, 12:46 AM #7

Why didn't you just lap the label side -- would've saved thickness & time?

-

05-18-2009, 07:25 AM #8

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote