Results 1 to 8 of 8

Thread: X-strokes on a coticule

Hybrid View

-

10-30-2009, 01:27 PM #1

X-strokes on a coticule

X-strokes on a coticule

Hi,

I know x-stroke pattern seems to deliver the best results, I'm not questioning that.

But I wanted to understand why it would work better than a straight or slanted stroke on a coticule when the cutting action is due to released garnets in a suspension vs. a synthetic hone where the cutting action is locked into the face of the hone. With the latter, I can conceptualize that the x-stroke varies the cut pattern on the edge across the blade better than a straight stroke, but I can't figure out why it would matter with a coticule in the slurry stage.

What do you think?

-Chief

-

10-30-2009, 01:35 PM #2

I don´t always do X-Strokes. So, technically I question that an X-pattern will deliver better results than regular/straight strokes.

There are stroke-types that can be counterproductive,

like the "8"-type pattern, that eventually leads to a recurve.

But I think both straight and x-stroke will (on a healthy razor) produce perfect edges

edit: when I use extra-little pressure I usually swith to an X-stroke,

because I can do it more evenly and steady without the need of a grip that is too firm for the "ultra light stroke"

-

10-30-2009, 02:07 PM #3

I imagine that there is more of a surety that all of the edge will come in contact with the abrasive surface despite any anomalies in the blade or in the surface (flatness or lack thereof) of the stone.

Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

The Following 2 Users Say Thank You to JimmyHAD For This Useful Post:

BHChieftain (10-31-2009), Bruce (10-30-2009)

-

10-30-2009, 02:21 PM #4

-

The Following User Says Thank You to BKratchmer For This Useful Post:

Bruce (10-30-2009)

-

10-30-2009, 02:28 PM #5

that´s why I mentioned the razor being "healthy"

But if the bevel is uneven, I rather correct it than circle around the fact.

But of course, the X-stroke with it´s varieties (e.g rolling) can overcome some minor flatnes issues. That´s a huge advantage

-

10-30-2009, 04:35 PM #6Coticule researcher

- Join Date

- Jan 2008

- Location

- Belgium

- Posts

- 1,872

Thanked: 1212

Exactly.

I don't think there is much difference between honing with or without slurry. Maybe, just maybe, there is some "give" in the slurry that could compensation for very minor variations in blade/hone straightness, but it would surely not be much. It is only an extremely thin layer of slurry in between the steel and the surface of the hone.

On the other hand, honing without the X-stroke is not entirely impossible. But it demands blade straightness in close tolerances, and the slightest variation will cause unevenness in the bevel width. The X-stroke, by continuously shifting the points of contact, can easily trace small deviations in blade straightness. A straight stroke can not achieve the same, so you have to hope the very edge will be able to occupy a space between the bevel boundaries , without developing a frown or some other lateral curve.

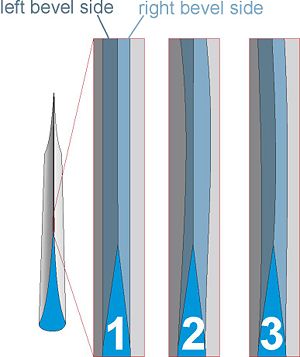

Let's look at a drawing from the wiki:

n°1 shows a perfect world: honed with straight or X-strokes would not matter. The very edge develops right in the middle between both bevel boundaries.

n°2 shows what happens if you hone a very slightly warped blade with straight strokes. The very edge is perfectly straight, but you can only hope that it will still be able to exist between the bevel boundaries. If not, this edge will develop a frown. To understand why, imagine what the point on the needle of a syringe looks like.

n°3 shows how the edge on the same blade will follow the curvature of the blade if it is produced with an X-stroke.

Slurry on a Coticule is not going to bend the rules of physics. It's not THAT magical.

Best regards,

Bart.

-

The Following User Says Thank You to Bart For This Useful Post:

BHChieftain (10-31-2009)

-

10-30-2009, 11:12 PM #7

I'm just curious. has anyone ever looked at the slurry that is created as you hone to see if there really are garnets being released from a coticule. A coticule is a hard rock and from just honing with little pressure I really don't get this release of garnets. maybe more of the garnets in the rock do the job as the blade goes over them. Now if you use a slurry stone and press as you go thats a different story. But even then I would want to know about the concentration of garnets.

No matter how many men you kill you can't kill your successor-Emperor Nero

-

10-31-2009, 10:33 AM #8Coticule researcher

- Join Date

- Jan 2008

- Location

- Belgium

- Posts

- 1,872

Thanked: 1212

This has been studied. Coticules are among the most studied rocks in the world. For some reason that seems to have more to do with natural formation of the rock than with the sharpening capabilities, they are a geologists wet dream.

First a link to a current scientific project that concerns Coticule:

Geomatics

Here's a link to a recent scientific publication about Coticule and slate mining in the Vielsalm area.

Geosciences 2 | Ardoise et Coticule en Terre de Salm

Here's an excerpt from the book. (in pdf)

The book is a multidisciplinary work by scientists covering a vast field of interests. It also addresses the mineralogical composition of Coticules, the physical principles of their abrasiveness, and why some layers are not commercially exploited.

To summarize, it is important that a Coticule releases fresh garnets into the slurry, during the honing process.

This happens because the already present garnets slowly abrade the surface of the hone, effectively releasing new garnets. That has been one of the major parameters in the old days to discern between various grades of Coticule. "Old Rock" for instance was a brand that only bought raw rock at various mines, coming from layers with the best reputation. Layers that combined fast cutting action with very fine abrasion.

This release of fresh garnets requires that there are already are loose garnets present on the surface.

When starting with only water, the garnets remain partially embedded in the surface, making the the polish different and the hone multiple times slower.

Here's a picture that shows the difference in polish:

A minority of Coticules do release fresh garnets, starting out with plain water, while being rubbed with a razor. It happens only very slow, but enough to notice the water becoming milky after a number of laps. It only happens with the softer specimen. I have noticed that the edges are better if those hones are regularly rinsed during the final stages of honing.

Bart.

-

The Following User Says Thank You to Bart For This Useful Post:

thebigspendur (10-31-2009)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote