Results 1 to 10 of 13

Thread: Fixing a frowning edge ?

-

08-09-2010, 04:57 AM #1Senior Member

- Join Date

- Aug 2010

- Location

- Vancouver, BC, Canada

- Posts

- 1,377

Thanked: 275 Fixing a frowning edge ?

Fixing a frowning edge ?

Forgive this long post from a newbie.

I've started work on an old, somewhat rusty Wade & Butcher razor. I'm learning more than I expected to learn. And my first lesson is:

. . . Don't buy a first razor with corrosion near the edge !

My tools:

600-grit wet-or-dry paper, taped to a 3.5" x 9" plexiglass base;

2000-grit wet-or-dry paper, taped to a 3.5" x 9" plexiglass base;

8000-grit ceramic stone, 4" x 2".

I've taken the edge back, past the rusty notches in it. The bevel shows clean steel, now. The edge looks smooth under a 10x diamond loupe.

On the 2000-grit and 8000-grit stones, the edge seems to touch the stone at the 1/4 and 3/4 points (from heel to toe). But the _middle_ of the blade seems just a bit above the stone -- water flows under it, instead of being pushed along.

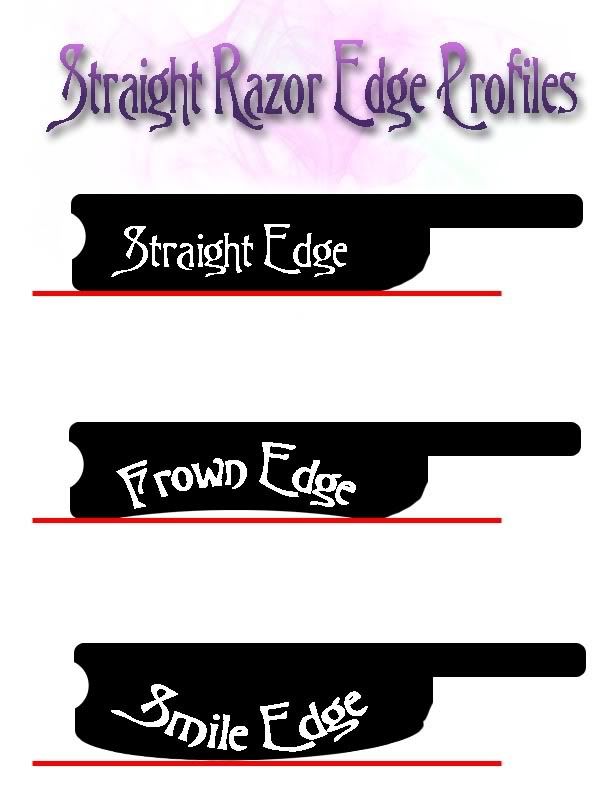

I think this indicates a "frowning" edge -- the opposite of a "smiling" edge.

After stropping, I can shave with it, but a Gilette Mach III blade is considerably sharper. So I know it's not finished.

Is there any secret to getting rid of the frown?

After reading the Wiki, it seems that my best bet is to go back to the 600-grit paper, and do straight strokes, with the razor's edge at 45 degrees to the long axis of the paper. And to keep doing them, until the edge is straight.

Thanks --

Charles

-

08-09-2010, 06:32 AM #2

Ya got it wrong on this one. A frowning blade can be seen if you hold the blade vertically and you're looking straight at it. If you hold the blade vertically with the edge on a piece of paper, a frown will show light in the middle of the edge. ie. the toe and heel touch the paper but the belly does not. Hope that makes sense. If you do the same thing, holding the blade vertically with the edge on paper and the toe and heel are off the paper and the belly touches the paper, that's a smile.

The first thing to contemplate is whether or not your honing surface for that paper is absolutely flat.

Ok, so here's my take on it. That razor WANTS to smile eventually. If your toe and heel touch on the hone, then more material will be taken from those areas faster than the belly and eventually the razor will develop a smile. However if you aren't careful on the honing, you'll end up with a really uneven pooched edge.

-

08-09-2010, 07:18 AM #3At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

Just to make sure we are all on the same page this is a frown

and a smile

and a smile

http://straightrazorpalace.com/works...dovo-24-a.html

It has a system written in there of how I fix them also, you will just need to adapt it to the sandpaper and stones you have...

-

The Following User Says Thank You to gssixgun For This Useful Post:

nun2sharp (08-09-2010)

-

08-09-2010, 07:19 AM #4

Here's what I'm talking about:

-

The Following User Says Thank You to red96ta For This Useful Post:

ferroburak (08-26-2010)

-

08-09-2010, 12:01 PM #5

Here is a PDF file from the SRP Wiki of a 1961 barber manual excerpt on honing and stropping. It addresses the issue of avoiding a frown with illustrations and text. IME since fixing a few like that I found the secret is not to buy them if they're in that condition.

Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

The Following User Says Thank You to JimmyHAD For This Useful Post:

Bazz (08-10-2010)

-

08-09-2010, 03:58 PM #6

- Join Date

- May 2005

- Location

- St. Louis, Missouri, United States

- Posts

- 8,454

- Blog Entries

- 2

Thanked: 4942

+1 Jimmy!!

I usually end up grinding them back to straight or smiley, but even with that and considering the spine wear, you usually get more bevel where the spine wear that caused the frown is.

Have fun,

Lynn

-

08-09-2010, 09:04 PM #7

Most frowns are more work than what they are worth! If you see one do yourself a favor and pass on it.

It is easier to fool people than to convince them they have been fooled. Twain

-

08-09-2010, 09:58 PM #8Senior Member

- Join Date

- Aug 2010

- Location

- Vancouver, BC, Canada

- Posts

- 1,377

Thanked: 275 Next time I'll know better!<g> [Or next time, I'll buy a new razor!IME since fixing a few like that I found the secret is not to buy them if they're in that condition.

Next time I'll know better!<g> [Or next time, I'll buy a new razor!IME since fixing a few like that I found the secret is not to buy them if they're in that condition.

Using magic marker (or machinist's bluing) on the bevel is a great idea, and the old barber's manual is very good.

There _is_ a frown (I checked by touching paper with the edge, and checking for light), it's slight (over about 1/3 of the blade), and I'll grind it out after vacation. I'll report back in a few weeks.

Thanks to everyone. It's a pleasure to be tutored by experts.

Charles

-

08-10-2010, 12:40 AM #9

Butterknife it then reset bevel, takes some time. I suggest a lower ~300 grit for speeding t up.

-

08-26-2010, 01:27 AM #10Senior Member

- Join Date

- Aug 2010

- Location

- Vancouver, BC, Canada

- Posts

- 1,377

Thanked: 275

My first re-grind, hone, and strop gave me a _usable_ razor. But today -- with very careful inspection -- I found that I have _almost_ eliminated the frown. And I've opened up a rust spot on the bevel (but not quite on the edge).

Back to 600-grit for some more grinding . . . My sequence will be 600- 1K - 2K - 8K.

As a result of trying to use a dull razor, my shave prep technique is much better than when I started!

I have a new Dovo from SRD on order. All the folks who recommend getting a "known-good" razor to start with --

. . . You're right.

Charles

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote