Results 11 to 20 of 25

Thread: Honing on glass

-

02-24-2013, 07:08 AM #11

Would doing this take the place of a leather strop?

-

02-24-2013, 07:25 AM #12Poor Fit

- Join Date

- May 2010

- Posts

- 4,562

Thanked: 1263

-

02-25-2013, 03:57 PM #13< Banned User >

- Join Date

- Dec 2012

- Location

- Chicago

- Posts

- 186

Thanked: 26

-

02-25-2013, 04:38 PM #14

Lillicrap hones have been around for a while to resharpen DE blades. I don't think straights have ever been honed on glass on a large scale.

-

03-06-2013, 03:02 PM #15Member

- Join Date

- Jan 2013

- Location

- Algiers Point, LA

- Posts

- 88

Thanked: 12

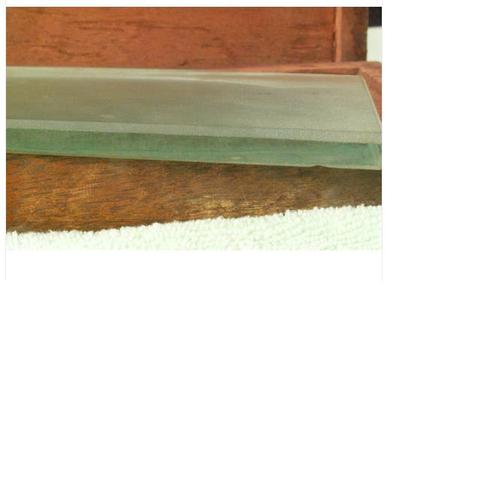

So kind of on the line of this thread... I found this... Would this be something to use my razor on??

-

03-06-2013, 03:37 PM #16< Banned User >

- Join Date

- Dec 2012

- Location

- Chicago

- Posts

- 186

Thanked: 26

Try it and see. I don't think it's going to hurt anything.

-

03-06-2013, 07:05 PM #17

Honing on Glass

Honing on Glass

When I was a machinist we called it Lapping, here is this forum they use the term different. When I was a Mechanic withe Diesel engines the old hydraulic injectors like on the Detroit Diesel engines the cones and the tip of the injector had to be Lapped. We would lay out a big glass sheet on a flate surface sometimes we would use a layout block, made of granite. I would use a perscibed medium that felt like a paste and work out any scratches on what we called matted surfaces. When I was a machinist we would use a machine. Look up Lapping on Wekipedia.

-

03-12-2013, 09:55 AM #18

Sure, spray it with 1 micron abrasive or 0.5 micron abrasive and hone away.

Diamond or Cubic Boron Nitride. It does not take much. As far as grit goes because of the solid glass

almost double the micron size before converting to a grit number to compare to a hone. Also twice as fast.

Use a light touch and let a glass slurry build up before giving up on the charge.

I had trouble finding value in the ceramic DMT ultra fine hone until I began giving it a gentle tune up

with 0.5 CBN.

Clean with water, glass will not act as an abrasive on hard razor steel but will straighten and

improve an edge.

You may find that a 2 micron, 1 micron, 0.5 micron spray sequence and a good wash with clear

water will work for some razors.

The cost of these sprays is such that hones are a better long term purchase. Sprays can also

be used on a leather or canvas/fabric strop. 0.5 micron spray on a strop or canvas does not hurt

and for me helps smooth the shave. Abrasive spray reduces the draw on leather for me which can

be a negative if it goes too far. A little goes a long way.

I mention this because glass with CBN could result in a harsh shave that a lightly pasted/sprayed

strop can calm. Never spray your better strop with anything coarser than 0.5 or 0.25 micron and then only

a little.

Try it on a second razor... and let us know.

-

03-12-2013, 11:13 AM #19

So, when I started shaving I did what my grandfather did.. He honed on a old razor hone and then finished on a glass bottle. I did it this way until I joined this site and found Shaptons and coticules. I find that coticules work much beter. The bottle worked at the time, but learning the newer techniques definitely improved my shaves. To each their own though.. It is definitely cheaper to go with a bottle.

-

The Following User Says Thank You to Wintchase For This Useful Post:

Dachsmith (11-30-2016)

-

03-12-2013, 04:51 PM #20

Barbers' manual ; and, Text book on taxidermy

by T.J. McConnaughay.

You can find this text at the openlibrary.org.

He gives detailed instructions on making and using glass hones on page 30.

I made one with double strength glass and used an escher for slurry.

Very nice finished edge.

Taxidermy and barbering... amazing read.

19Likes

19Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote