Results 41 to 50 of 50

Thread: Solving a Mystery

Threaded View

-

04-30-2013, 04:30 PM #1This is not my actual head.

- Join Date

- Nov 2009

- Location

- Middle of nowhere, Minnesota

- Posts

- 4,624

- Blog Entries

- 2

Thanked: 1371 Solving a Mystery

Solving a Mystery

Awhile ago, a member posted about a problem razor that wasn't giving satisfactory shaves, despite multiple honing efforts and passing all tests preliminary to the shave test. The particular brand, size, and grind of razor is one of my favorites, and I was curious about where the problem might be, so I asked the member to let me take a look at it.

The first thing I did with the razor was to attempt a shave with it. While it was able to shave, the results were unsatisfactory.

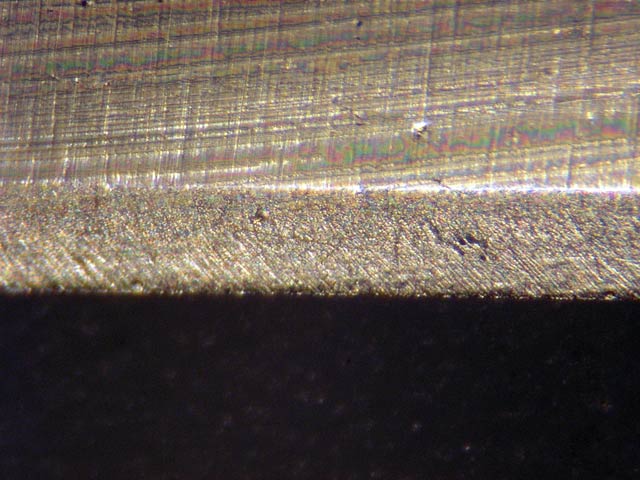

This morning I finally had a chance to give the razor a closer look and see if I could figure out what was going on. Normally with a razor like this I use my stereo microscope to determine which stone I need to start with. Here is what I saw when I looked at it with my microscope:

The picture doesn't capture things quite as well as actually looking through the microscope, but it does represent things well enough to show what I'm seeing.

After I took the picture, I thought it might be a fun learning experience for some of our beginners to see if they can figure out what's going on and what it will take to fix the problem, based on the picture and the clues in my post.

I'll give you all some time to ponder, and I'll post some more pictures as I continue honing it.

...to be continued...

Strange women lying in ponds distributing swords is no basis for a system of government.

-

The Following User Says Thank You to HNSB For This Useful Post:

Jmveness (05-03-2013)

70Likes

70Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote