Results 1 to 10 of 11

-

03-03-2017, 10:09 PM #1Member

- Join Date

- Feb 2017

- Posts

- 35

Thanked: 5 CPM 3V - kitchen, pocket and straight razor ?

CPM 3V - kitchen, pocket and straight razor ?

CPM 3V - now that it's been around for a while, have you had a chance to test it out?

Thoughts on kitchen or chef knives made from it? (Meglio brand knives look beautiful for all except the price tag)

Thoughts on straight razor made from it?(Are there any? )

Thoughts on pockets knives? (Bark River seems to be the go to brand)

Is there a sweet spot in that 58-62 hardness rating that you like better?

Most of the conversations I could find online were first impressions from ~2010. It's 2017 now, so I'm curious.

-

03-07-2017, 10:59 PM #2Member

- Join Date

- Feb 2017

- Posts

- 35

Thanked: 5

And sword?

Pretty badass - https://www.youtube.com/shared?ci=BS03QmCHU1k

Who needs an axe?

-

03-07-2017, 11:58 PM #3Previously lost, now "Pasturized"

- Join Date

- Oct 2005

- Location

- Winnipeg Manitoba Canada

- Posts

- 1,333

Thanked: 351

If there is a need for better steel to be used for knives and razors, then by all means, lets do it. But, if the current steel being used, performs for the job it is meant for, why seek out something else that is not intended for said purpose, and is more costly? Just because we CAN, is not a good good enough reason.... We could make a kitchen sink out of this stuff, but plain ol' 18-8 stainless is more than good enough, looks great and lasts forever, and it's priced right.

All I can say is that I sure as heck wouldn't want to try to hone a razor made of this stuff.

CPM 3V Powder Metal Tool Steel

CPM 3V is a powder metal tool steel with a unique chemical composition that results in tooling with an outstanding combination of properties including high impact toughness and good wear resistance. The impact toughness is enhanced by the fine grain size, small carbides, and superior cleanliness of the powder metallurgy (PM) microstructure.

APPLICATIONS: CPM 3V should be considered for service in blanking & sizing dies, shear blades, cold and hot forging punches, powder compaction tooling and many other applications where a combination of strength, wear resistance and toughness is required.

"Aw nuts, now I can't remember what I forgot!" --- Kaptain "Champion of lost causes" Zero

-

03-09-2017, 07:20 AM #4Member

- Join Date

- Feb 2017

- Posts

- 35

Thanked: 5

Fair point. I love the kitchen sink analogy.

This material seems to get great reviews from Bushcrafters. I'm just wondering if the edge retention would translate into less need of work?

You know, harder to fix, but less frequency of needing a fix.

You might have to excuse my ignorance. I'm just learning about the immense range in metals so I'm not familiar with which steels are the benchmarks for a given task. I thought I'd start with this one since it seems to be popular and has such an irresistibly catchy name.

-

03-14-2017, 02:44 PM #5

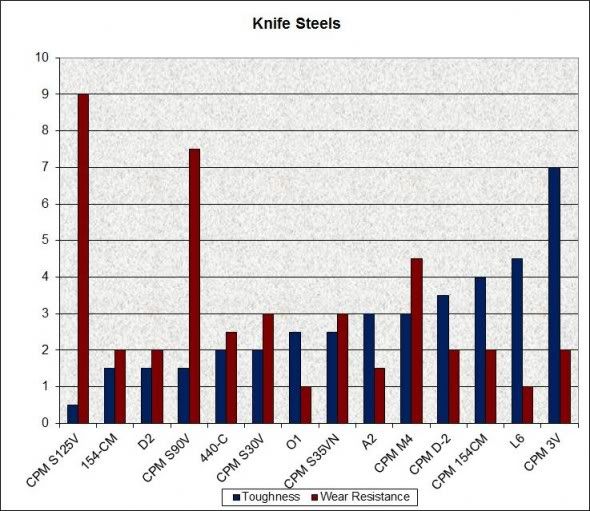

The value in 3V lies mainly in it's toughness. Not it's edge retention. Which is why you'll see it in a lot of Bushcraft style knives.

Have a look here:

For razors if you want something to stay sharp for a loooong time you need 2 things:

1) A fine grain

2) high wear resistance.

The fine grain is for a comfortable shave. Something about the courser alloys just doesn't sharpen up well to that ultra sharp edge that you want in a razor. If it's not ultra sharp it's not going to shave comfortably.

A lot of the steels in that chart with high wear resistance are not fine grained. (S90V, S110V, S30V, S125V all have large carbides in it to keep them sharp for a long time..but that very keen edge will elude you forever)

There are however some high wear steels that have fine grain nowadays, like K110, M390, 20CV, ZDP189, ELMAX etc etc

The high wear resistance is debatable. Some people like to be able to do easier honing. Which is where you get remarks like "I'd hate to be the one sharpening that" in high wear steels (and it really can be a bear to hone or sharpen certain steels, especially when a lot of metal needs to be removed.

So if I were to make a razor out of a steel meant to be sharp for a much longer time I'd probably go with M390. High corrosion resistance, high wear resistance and more than tough enough to be used in a razor.

-

The Following User Says Thank You to LX_Emergency For This Useful Post:

Hirlau (08-01-2017)

-

06-09-2017, 08:15 AM #6Member

- Join Date

- Feb 2017

- Posts

- 35

Thanked: 5

Interesting. M390. Hm.

Is there an easy way to determine grain size?

-

07-03-2017, 07:49 PM #7

-

07-10-2017, 09:02 PM #8aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

To see fine grain, many of us will heat treat a "coupon", or piece of steel, heat treat it, and break it. That tells a whole lot. It should look silky, unable to really see any "grain". If you see grain like sand, it's either a bad HT, steel, or both.

It was interesting to see the O1 rating as it's one of the steels used in razors, along with 1095.Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

08-01-2017, 07:12 AM #9Member

- Join Date

- Feb 2017

- Posts

- 35

Thanked: 5

What are you guys using in referencing the properties of the different metals?

-

08-05-2017, 12:29 AM #10Member

- Join Date

- Feb 2017

- Posts

- 35

Thanked: 5

Aka, is there a document or something I can check out or is this all personal experience?

6Likes

6Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote