Results 1 to 10 of 12

Thread: Hi, New member

-

04-23-2013, 02:59 AM #1Junior Member

- Join Date

- Apr 2013

- Location

- Burlington & Toronto

- Posts

- 20

Thanked: 2 Hi, New member

Hi, New member

Hi all,

New member here.

Lover of all things metal, mechanical, and sharp, so I took my interest of sharp metal objects as far as I could and became a Tool and Die Maker. Nowadays I'm an Engineering Planner in the Naval and Aerospace defense industry, but I still have a huge interest in knives, straight razors, and metallurgy Since I'm no longer making tooling and dies for the aerospace and space industry, I still have that itch to work with my hands so I make things now and then (if you're on instagram, check me out: atrokz). Hoping to post up in the forge section in the future when I have something to show you guys. Until then, I'll continue to shave with my ancient unlabeled razor and lurk the advice sections on how to get the most out of it.

I hope to enjoy my stay here, help where I can, and gain knowledge where I can.

Cheers!

A

-

The Following User Says Thank You to AFisher For This Useful Post:

Man (04-25-2013)

-

04-23-2013, 03:07 AM #2I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Looking forward to seeing some of your creations! Welcome!

Burls, Girls, and all things that Swirl....

-

04-23-2013, 03:10 AM #3'tis but a scratch!

- Join Date

- Oct 2010

- Location

- Durango, Colorado

- Posts

- 2,080

- Blog Entries

- 2

Thanked: 443

Welcome, A, to SRP. There are a few machinists or retired machinists here, and overall an astonishing amount of knowledge you can draw upon. Enjoy!

"These aren't the droids you're looking for." "These aren't the droids we're looking for." "He can go about his business." "You can go about your business."

-

04-23-2013, 03:28 AM #4Senior Member

- Join Date

- Jan 2012

- Location

- Boise, Idaho

- Posts

- 217

Thanked: 36

Welcome to the forum!

Cheers,

JC

-

04-23-2013, 01:34 PM #5Junior Member

- Join Date

- Apr 2013

- Location

- Burlington & Toronto

- Posts

- 20

Thanked: 2

Thanks guys. I'll load up a few pics soon as I'm home and not on a mobile device. Getting sore thumb joints on this dinky little device.

-

04-23-2013, 02:52 PM #6Junior Member

- Join Date

- Apr 2013

- Location

- Burlington & Toronto

- Posts

- 20

Thanked: 2

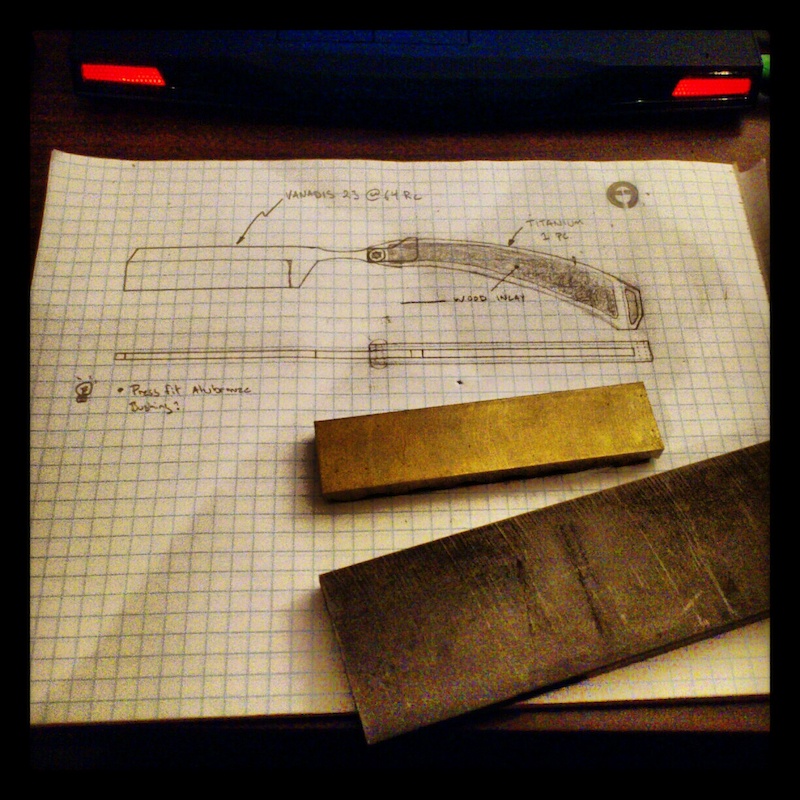

Excuse the grainy, hipstagram filted photos:

This is my plan:

Vanadis 23 blade, I've already heat treated the metal to 64Rc, and will be wire EDM cutting the profiles. This through hardening will, imo, provide a very strong blade as the hardness is equal throughout. The material is an offcut for a metal cutting die I made, designed for 1,000,000 cycles shearing .125 stainless. I think I will aim for a wedge grind, and have a fairly thin blade profile (thinking .125") as the hardness of the blade in combination with the wedge grind should keep things fairly stiff, while still allowing the edge to get as close as possible without riding on the spline. If anyone has ideas how to improve it, I'm always open to suggestions.

Handle is going to be Titanium. I will aim for a 1pc handle, but if EDM time gets reduced I may turn to scales and waterjet them with a sapele wood spacer.

I'd also like to get inlays of sapele wood, but we'll see how the ti handles turn out on their own, and if I want to do some of my own 'artwork' on them sans the sapele or ipe inlays.

Bronze pivot bushing, or bearings.

Custom hardware, I haven't designed yet

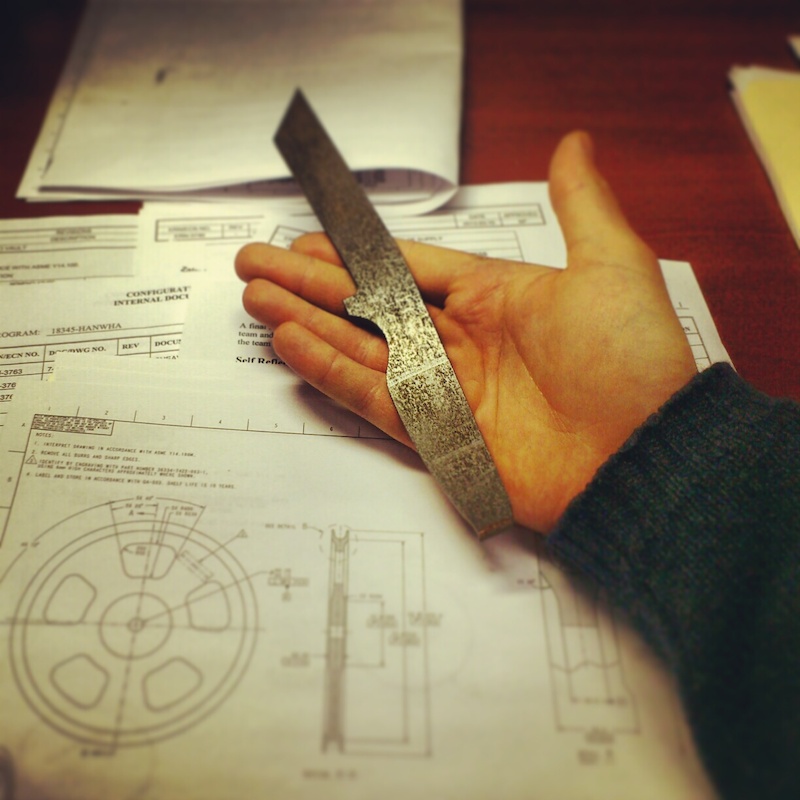

here's a combat knife proto I'm working on for some special ops guys. Small batch, this is a mild steel part cut to test both the ergonomics and grind profiles. Ordering D2 and CPM-3V for the final versions. Ipe wood handles, titanium or phosphorus bronze custom screws.

Cheers!!

-

04-25-2013, 12:07 AM #7

Thanks for the introduction, A! Welcome aboard!

-

04-25-2013, 12:13 AM #8

Welcome!

I hate to admit it but as a non-metallurgist/machinist kind of guy (although I'd love to learn someday) I haven't the foggiest idea what much of your plan entails. However I do know I can't wait to see how it comes together!

Be sure to keep us posted

It was in original condition, faded red, well-worn, but nice.

This was and still is my favorite combination; beautiful, original, and worn.

-Neil Young

-

04-25-2013, 08:52 AM #9Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Welcome to SRP

It sounds like you have a fair amount of skill that an be utilized in the making of a straight razor.

I noticed that you mentioned a .125 for the profile of the blade. If you mean the thickness of the spine then you may want to reconsider. The general rule of thumb to obtain the proper angles on a razor is to take the width of the blade and divide it by the thickness of the spine. You want to stay with in a ratio of 3.5:1 up to a max of 4:1 . An example...if you want a blade with a 1" width then the spine thickness should be at least 0.250" ( 1/4"). This results in a small & strong bevel that is not prone to micro-chipping.

Hope this helps Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

04-25-2013, 09:57 AM #10

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote