Results 1 to 10 of 10

25Likes

25Likes

Thread: Pewter disease or Tin Pest

-

05-17-2016, 01:53 AM #1

Pewter disease or Tin Pest

Pewter disease or Tin Pest

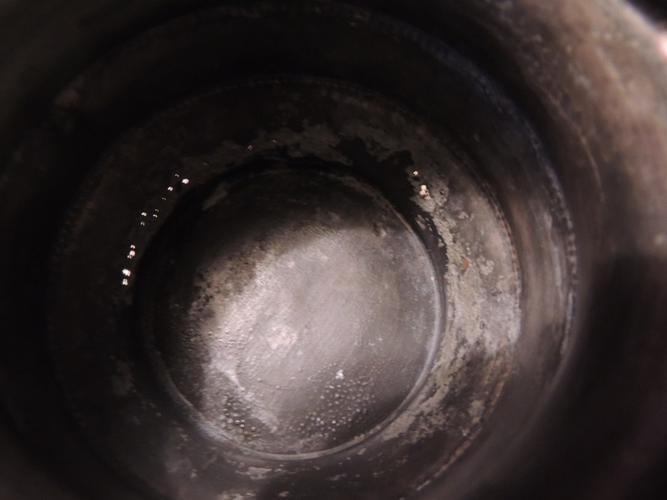

I have a shaving mug that is marked 1500 Quadruple Plate Silver on the bottom. I assume it is Pewter underneath. A short while ago I noticed that there was some soap on the outside and bottom when I got done using it. I wondered how in the heck did that get there? Then I noticed the inside of it is rotting away and full of pinholes and bigger. I had never heard or thought about this until this happened. Cold temperatures and wet, maybe acid in the soap....

Does anyone else here know about or experienced this?

-

05-17-2016, 01:59 AM #2

Looks like at one time it held some Vegetal ,,,,

-

The Following User Says Thank You to Hirlau For This Useful Post:

sharptonn (05-17-2016)

-

05-17-2016, 02:02 AM #3

,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,

-

05-17-2016, 02:41 AM #4

Looks like it is epoxy time. A nice, thick layer and perhaps a few marbles thrown in to make for some good stirring?

I feel anything else would have the bottom out!

Last edited by sharptonn; 05-17-2016 at 03:19 AM.

"Don't be stubborn. You are missing out."

I rest my case.

-

05-17-2016, 02:48 AM #5

Chlorinated water and harsh soaps can do that to silver and pewter.

Clean it with a toothbrush, and solder the holes with silver plumbing solder (non acid rosin core). Then file the solder back smooth.Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

-

05-17-2016, 03:23 AM #6

I have some older now against the rules partially lead plumbing solder. Is that what you mean? Would I use an soldering iron not a flame? The metal is very thin and fragile in the affected area. Very easy to overheat and melt out larger. I have read that once this starts it is self generating for lack of a better term. If I just cover it up will it continue underneath the repair.

I have some older now against the rules partially lead plumbing solder. Is that what you mean? Would I use an soldering iron not a flame? The metal is very thin and fragile in the affected area. Very easy to overheat and melt out larger. I have read that once this starts it is self generating for lack of a better term. If I just cover it up will it continue underneath the repair.

This is a cheap to me piece and not an heirloom etc. but I would be interested in fixing it for no other reason than it would be a fun project and a learning experience.

Tim

-

05-17-2016, 03:50 AM #7

-

05-17-2016, 06:14 AM #8Previously lost, now "Pasturized"

- Join Date

- Oct 2005

- Location

- Winnipeg Manitoba Canada

- Posts

- 1,333

Thanked: 351

*ANY* plumbing solder that has a core, will have an ACID based core.... Plumbing flux, usually in a small shoe wax/paste size tin is also ACID based. Rosin flux is used in the electronics industry. As for fixing pewter.... I am NOT the guy to ask. I've wanted to dabble in spinning pewter on the lathe, but so far I have not had time to do so.

I would suggest as others have, to just clean it well and use some form of epoxy resin to build up the bottom. No chance of melting the darn thing in a repair event and epoxy should outlast any pewter repair. If there are through holes, some masking tape on the outside bottom will prevent a thinner epoxy from running out the hole. Once the epoxy is hardened, you can remove the tape.

If the item was of value to you, then by all means, send it to a goldsmith/Jeweler who has experience with working in pewter. That sort of repair work is not for the unskilled. A goldsmith would probably replace the entire bottom with a fresh sheet of pewter, and welding it in the corners. It would then be spun on a wooden mandrel on a lathe to smooth out any bumps.

[edit]Pewter is mostly tin with small amounts of other metals added to it. Not like old fashioned plumbing solder which is around 60/40 tin/lead. You would be better off with the new plumbing solder which is basically just tin, but much of it still has acid flux.

Regards

ChristianLast edited by kaptain_zero; 05-17-2016 at 06:32 AM.

"Aw nuts, now I can't remember what I forgot!" --- Kaptain "Champion of lost causes" Zero

-

05-17-2016, 07:05 PM #9

You definitely want silver solder instead of lead solder and definitely nothing with rosin flux in it. Ideally you want silver bearing solder.

For pin holes you can usually just use a soldering iron or soldering gun to fill the holes. For larger holes you usually have to pull out a torch and do more of a brazing maneuver on the holes. You do have to be really, really careful with a torch though because it will burn through silver plate in the blink of an eye.

Yes, the rot will continue under epoxy, but it will also be substantially slowed down by the epoxy.

Since you say it is an inexpensive/non-heirloom piece, it might be easier to just epoxy the holes closed and then coat the inside with mirror finish to seal it all up.Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

-

05-17-2016, 10:22 PM #10

Thanks for the replies. I will think about this for a while as I have to pack for my fishing trip tonight. Nothing is going to get done for at least a week!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote