Results 1 to 10 of 20

-

04-02-2021, 01:38 PM #1

Werner Breidenbach – the Grand Old Master of straight razor grinding in Solingen

Werner Breidenbach – the Grand Old Master of straight razor grinding in Solingen

This is a thread to honor one of the best craftsman and master of his art that Solingen ever has seen. And - by the way - the oldest still working razor grinder in Solingen.

Werner Breidenbach started as apprentice in razor grinding at Paul Drees company in Solingen in 1948. Until closure in 2003 he was to remain loyal to this company as straight razor grinder and later also as owner for more than 55 years. During this time and also later he did not only grind and sell razors under the Paul Drees company name. It was usual in Solingen, that -real good- factories also ground razors for larger other companies who only put the brandname and logo on the finished razors and sold them under their name.

So this thread is not only a Paul Drees story, you will also see a lot of other work and razors grinded by Werner Breidenbach for different companies. And I am quite sure that a lot of you also have Werner Breidenbach ground razors with well known brand names - without nowing the real origin.

But lets come back to the history of Paul Drees first.

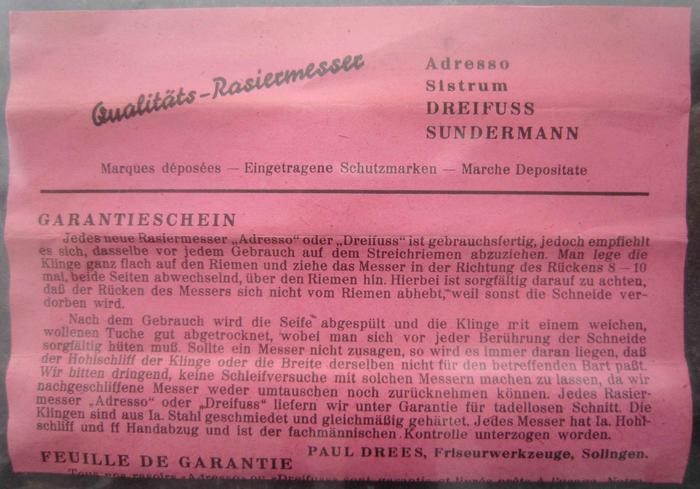

In the picture above you can see an Adresso razor. One of the brand names of Paul Drees.

The name Adresso is build of the following characters. At the end „SO“ for Solingen – as many Solingen companies did to form their brand names. The middle „DRES“ stands for Drees though one „E“ is missing. But what stands the „A“ for?

Paul Drees started the business as razor grinder sometimes after WW1. But the later company itself was not founded as Paul Drees but as Alfred Drees in 1932/33. So the „A“ stands for Alfred who was the son of Paul Drees. Here is a picture of an old Alfred Drees -Adresso- razor (unrestored) with the cardbox.

So why this?

It helps to understand to know something about the organisation of the working and factory business in Solingen in the 19th and 20th century.

In Solingen a lot of workings have been done by homeworkers in one-man-business units. The grinders had their little workshop – in Solingen called „Kotten“ – with all necessary equipment, often in the basement of their homes or in barnes in the neighbourhood. Sometimes a couple of single homeworkers shared a workshop.

Paul Drees was such a homeworker. As many others, he worked for different companies as straight razor grinder. He got the blankets from the companies, took them home to the workshop, ground and polished them and returned the finished razors to the factories. Sometimes the grinders also mounted the razors in scales and honed them. But in general, the job of scale-mounting and honing of the razors was a different business and teaching profession.

So around 1932 Paul Drees made the decission to grind razors (also) with his own brand and for his own wallet. But at the beginning he still needed the work from other factories as a homeworker, because of the money and reputation. And the companies didn’t like homeworkers that were also doing business on their own. So the company was founded on the name of his son Alfred. Later the company name was than changed to Paul Drees.

Werner Breidenbach grew up in Solingen among grinding and razor fabricating workshops.

A lot of his family members have been razor grinders or scale-mounters and honers. As a young boy Werner always played around and looked through the windows of the old workshops. He never wanted to do anything else than to learn how to grind straight razors.

So at the age of 14 he started his apprenticeship at Paul Drees. After three and a half years Werner Breidenbach passed his examination as straight razor grinder in 1951. It was usual that the examination itself was not taken in the same company where you have learned. So Werner Breidenbach passed the examination at Fitz Bracht (Dovo) and then returned to Paul Drees.

The Paul Drees company still ground razors for other companies but also fabricated a lot in their own name at this time.

Brand names beside the Adresso have been Sistrum, Dreifuss and (very few) Sundermann.

A lot of Paul Drees razors were sold to Italy. The Italian market for straight razors was very ambitious. Italien barbers liked the razors very thin ground – singing razors, demanding high requirements on the skill of the grinders.

But this high skills and their presence in the Italien market helps the Paul Drees company to survive longer than much other razors manufactories.

From the late 1950‘s the market for straight razors was going down in general, it nearly dissappeared beginning of the 1970’s. An exception was Italy. And in Solingen only razor factories could survive at this time that exported to Italy or Japan.

After the last razor grinder with the name Drees had died, Werner Breidenbach took over the company in 1982.

In the 1990’s Werner Breidenbach offered several of the larger (former) razor companies in Solingen to educate and train new straight razor grinders. But at this time, there was no interest from the companies. Later then, when straight razors got popular again, they would have embraced this offer and asked several times.

But Werner Breidenbach had allready retired. Before, a film was made about him and his old craftmanship of razor grinding.

Times changed – the work stays the same. Werner Breidenbach grinding straight razors - in the late 1950 - 2001 - 2020

In 2003 the Drees company was closed and the history of Paul Drees razors ended officially.

But not the history of Werner Breidenbach razors …….!

-

The Following 16 Users Say Thank You to hatzicho For This Useful Post:

32t (04-11-2021), Badgister (04-04-2021), BobH (04-02-2021), DZEC (04-02-2021), Euclid440 (04-02-2021), JBHoren (04-02-2021), jfk742 (04-06-2021), JOB15 (04-06-2021), kyriakos (04-11-2021), Martin103 (12-25-2021), MichaelS (04-05-2021), outback (04-02-2021), RezDog (04-02-2021), rolodave (04-02-2021), sharptonn (04-05-2021), Steve56 (04-11-2021)

-

04-05-2021, 11:01 AM #2

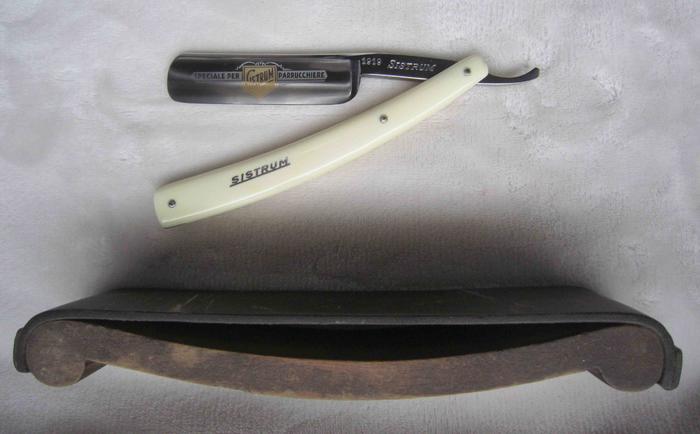

Sistrum Razors

The Paul Drees Sistrum model 1919 has been mainly produced for the italian market. Production years have been between 1950 and 1970.

The razor is very thin ground.

Italian barbers demanded the straight razors to be very thin ground beginning from the hollow all over the belly to the edge, so that you can easily bend the edge while running over your thumb nail.

The razor had to produce a very clear high sound when hit on the toe.

The wholesalers for Italy often send tuning forks to the razor grinders and each and every razor has to sound exactly according to the tune of the fork.

One reason for that was that the razors needed to be very flexible because in older times some traditional barbers shaved in a way, that they hold the razor with both hands - the spine between thumb and forefinger - not on the tang.

Another reason was that the razors could be easily honed and still used without regrinding, even when they had been worn out a lot and the edge has already reached the thicker part of the belly.

On the very old Sistrum that were produced by Alfred Drees, you can find the engraving of the instrument on the tang. In later times that disappeared.

Hope there are more Sistrum razors out there and will be shown here!

-

-

04-11-2021, 02:32 PM #3

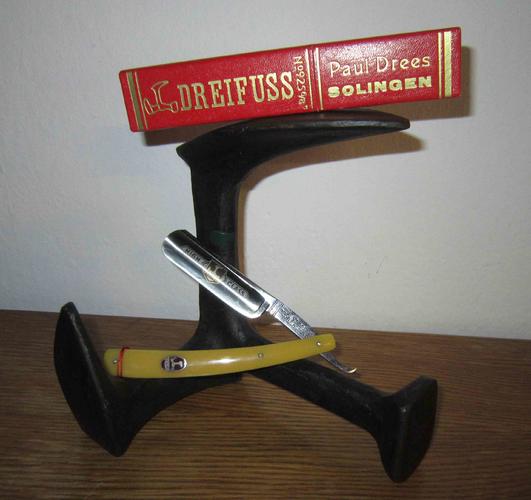

The Dreifuss Models

Under the name Dreifuss a lot more models have been made than for the Sistrum mark.

A lot of them have also been produced for the italian market, but also for Europe and you will find some of them especially in Eastern Europe.

Some of the Dreifuss models were made from Böhler steel, others of Kayser-Ellison-Steel.

Kayser-Ellison-Steel was licensed to the Solingen drop forge Hugo Herkenrath from Sheffield Kayser Ellison & Co. Hugo Herkenrath produced mainly scissors, but also razor blankets from this steel, the sister company Friedrich Herkenrath special DE blades (from the 1940’s known as „Apollo“).

According to the words of Werner Breidenbach, blankets from Kayser-Ellison steel have been more expensive than such from Böhler steel.

But the steel was finer grain, easier to grind and holds an edge longer.

Most Dreifuss models have been made of Kayser-Ellison steel. An interesting issue is, that just the premium Gold model of the 1919 series was „only“ made from special Böhler steel.

Also the common 1919 Dreifuss model was made of Kayser Ellison steel - whereas the Sistrum with the same model number was made of Böhler steel.

I identified the following model numbers of the Paul Drees Dreifuss series so far:

10

25

39

89

99 (super)

100 (special)

925

1919

As for the meaning of these numbers – even Werner Breidenbach doesn’t really know the sense behind them.

He just told me that some of the numbers have been adopted by several razor companies (not only Paul Drees) from the original numbering that Carl Friedrich Ern once used for his razors.

Interesting subject for some future investigations.

Regards Peter

-

-

04-11-2021, 02:59 PM #4Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,334

Thanked: 3228

Thank you for taking the time and effort to share this detailed information with the forum.

BobLife is a terminal illness in the end

-

The Following User Says Thank You to BobH For This Useful Post:

hatzicho (04-11-2021)

-

04-25-2021, 02:11 PM #5

As already mentioned in my first post here, smaller razor factories and homeworkers didn’t only fabricate razors under their own brandname but also worked for larger companies and wholesalers.

Indeed there are quite a lot of Solingen companies with well known brandnames that didn’t produce one single razor by themselfes.

Most of the real large razor companies had their own grinding workshops, but they sell and exported razors in such numbers, that they were supported by others.

So in the following you will see some examples of razors ground by Werner Breidenbach for other companies or in the name of other factories.

One company that Werner Breidenbach worked for and ground thousands of razors was Henckels. He made the carbon steel razors as well as the famous Friodur.

The Henckels company was probably the first to succeed in manufacturing a razor made of stainless steel using a special hardening process, which was not (or almost not) inferior to carbon steel knives in terms of sharpness and blade life. The so-called ice-hardening was developped in 1939 and was patent-registered under the term Friodur.

Although Friodur knives only have a hardness of around 56-57 HRC, the steel is very fine-grained and can be ground very thin and sharpened well.

Werner Breidenbach is convinced that the Friodur razors are among the best razors ever produced. He (still) shaves with a Friodur since about 40 years.

But also the carbon steel razors are exceptional shavers. Here is one ground by Werner Breidenbach:

Werner Breidenbach found this razor a few years ago on a market, so he cannot be absolutely sure that he was the one who ground it. But every razor grinder has his little distinctive marks or small signs where he knows – this could at least be one of mine.

One of the most thought after razor in the collectors scene ist he following:

The brandname was first registered by Ferdinand Herberz in Solingen Ohligs 1864. In the 1950’s Juan Vollmer was allowed to use the Palmera name and sign. Werner Breidenbach knew him very well and ground a lot of Palmera razors for him.

When Juan Vollmer moved from Solingen to Spain, about 6 very good Solingen razor grinders followed him in his workshop and stayed there for years to work for him. But also Werner Breidenbach still ground razors in Solingen for Juan Vollmer.

Another large well known company Werner Breidenbach worked for was Puma. Founded 1769 by Johann Lauterjung, Puma was one of the big palyers in the knife industry in Solingen in the 20th century.

Werner Breidenbach ground razors for about 20 years or longer for Puma. Here is an example of a special edition he produced in the last years with the Puma logo:

Another member of the Lauterjung family founded the Tiger knife company in 1873. They also made razors but not in very large numbers. Today only a few of them have survived in collectors hands.

Regards Peter

-

-

04-29-2021, 07:36 AM #6

Someone asked me if the Video from Werner Breidenbach is still available...

Yes it is!

You can see a shortened version on youtube here:

The Video describes all main necessary steps in razor production to get from a blanket to a shave ready razor.

Regards Peter

-

-

04-29-2021, 11:15 AM #7

I like the way he does 4 spines at once.. Funny you never see them cooling the blades in these old videos yet the wheels look like they are going super fast..Shame it ended at the honing..

Thanks , nice video..

-

04-29-2021, 11:29 AM #8Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,812

Thanked: 562

I notice he used only a piece of cloth to protect his finger. I’m sure he could feel how hot the blade was getting and knew when to back off through decades of experience.

David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

04-29-2021, 12:35 PM #9

Well active cooling with water is only done during grinding of edge, hollow and belly with the hollow grinding machine.

The work at spine and angle with the belt grinder don’t need cooling, there is no danger that a lot of heat will go into the blade itself. Also the old masters are so fast and experienced, the steel simply won’t stay very long in contact with the belt to produce much heat.

The step of „Pliesten“ (rough polishing) is done on the wheels with oil/ emery mixture. So there is a certain cooling and the blades won’t get really hot, just a little bit warm.

The most heat is produced during polishing with pastes. Here the wheels run at high speed ≥ 3000 rpm and you put a lot of pressure on the blade. So I normally have a small can with water standing beside where I put the blade from time to time. Also for this step I normally put cut-resistant gloves on to protect my hands here since the blades are very thin at this stage of work, nearly sharp and you work with high pressure. The old guys didn’t need that. Their experience and speed at work is unbelievable. A small piece of cloth around their fingers is enough and, as you mentioned correctly, they feel exactly how hot the blades get and when to interrupt the work shortly.

Watching Werner Breidenbach nowadays - and he is getting 88 years in a few weeks - he hasn’t lost anything from his skills nor his speed at work. Simply amazing to see him grinding.

Regards Peter

-

-

05-23-2021, 10:44 AM #10

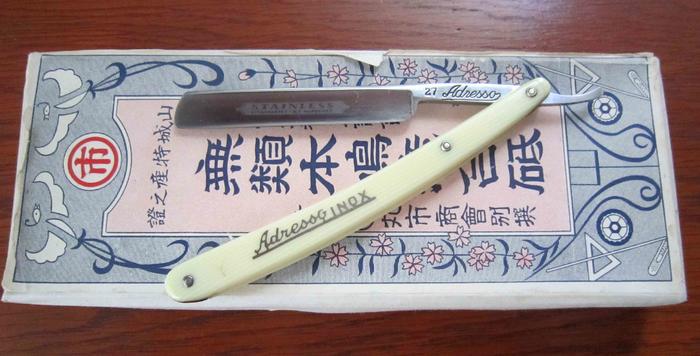

Some Special Adressos

We talked already that the Sistrum razors were mainly produced for the italian market. Very thin ground and mostly 6/8 – 13/16 inch wide.

The Dreifuss were generally sold all over Europe, also thin ground, some variations like the shown „Oro“ - gold model.

Much more variations exist from the Adresso razors.

A lot of the „standard version“ in 5/8 and 6/8 have been sold in Germany through small city stores that were selling Solingen cutlerware. Most oft hem had a small grinding workshop intergrated and did a lot of (re-) sharpening work on knifes, scissors and also razors.

In the region of middle Germany these were called „Stadtschmiede“ which can be translated to town-smith.

But they weren’t necessarily really blacksmiths, the origin of the expression came from the work as smith in older times though.

Paul Drees also had a wholesaler in Switzerland, where mostly small razors were sold.

Also there was a representative in Finland. Mostly small wedges in 4/8 with oxidized tang were sold in the baltic region.

A small stainless version, that is mainly found in Japan also exists. As typical for Japanes razors with an intermediate size of 7/16.

And of course some nice special Adressos have been made. So following is some eye candy:

Some nice spine-work....

... with nice scales in horn:

and ivory:

Regards Peter

-

138Likes

138Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote