Results 441 to 450 of 523

Thread: That 1700's Show

-

09-23-2020, 05:48 PM #441Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

The short answer is no. Somewhere on this forum, I have the measurements. Basically they start out with about a 1/4" spine thickness at the toe and taper all the way down to about 1mm at the tail. The spine thickness to blade width is critical to making it work correctly as a razor. The other considerations are the steel type, heat treatment and grind. I think that all are important considerations to how these old razors performed and felt.

-

09-23-2020, 09:34 PM #442Senior Member

- Join Date

- Jul 2020

- Posts

- 270

Thanked: 44

Progress so far on my blade.

I think my stock might be too thin however I'm using 3/16ths and at the widest point the blade is just under 7/8ths.Last edited by thp001; 09-23-2020 at 09:39 PM.

-

09-23-2020, 11:27 PM #443Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

-

09-23-2020, 11:36 PM #444Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Also, you are going to need to grind a bevel to the area between the edge and the pivot hole (the area circled in red). Look at all the pictures in this thread and you will see what I mean. This bevel allows the blade to close into the scales. Otherwise the portion of the razor that needs to fit between the scales is going to be wider than the opening between the scales.

-

09-24-2020, 01:01 AM #445

-

09-24-2020, 04:19 AM #446Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

-

09-24-2020, 06:29 AM #447

-

09-24-2020, 06:36 AM #448

-

The Following User Says Thank You to ScienceGuy For This Useful Post:

Geezer (09-24-2020)

-

09-24-2020, 02:41 PM #449Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

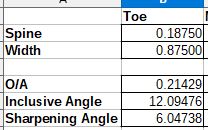

Correct, we need the measurement from the edge to the place where the spine contacts the hone (top of the grind line). With this style of razor, it varies on the same blade due to the curved belly and straight grind line along the spine. So I take the measurement in three or four places.

Do you have any of those pictured razors to get measurements from, or more photos? I would be really curious to see how they are doing that. Are they using a wide wedge like you say or are they tapering the steel clear back from the spine so that there is no visible line? The scales will flex to a certain point. Some flex and spring action of the scales is good, but there are other issues if it is too much. For instance if the steel is wider than the scale opening, the edge of the steel will dig into the edge of the scales if there isn't some kind of taper or bevel to the steel. In the case where the steel is wider than the scale opening, I've even seen where there is so much "spring" in the scales that they push the blade out of the scales causing the razor to "open up" a little. Below are some pictures of a razor that I examined. I have a bunch more pictures of it with measurements if it would be helpful to you guys. I would love to see more people making replicas of these. It is a great style of razor that so often overlooked. With all the Damascus, G10, fancy file work, and Star Wars looking razors out there it would be great to see some old fashioned wedges and bone that simply shave well. Originally Posted by ScienceGuy

Originally Posted by ScienceGuy

Notice how thin the steel is below the edge as compared to the same location on the spine. This is not for style. This is so the razor will close.

-

09-24-2020, 03:02 PM #450

I don't have access to any right now, unfortunately. Often the ones I'm describing either had a somewhat thin wedge or none at all (cut into the horn of one of the scales to make a quasi wedge). The ones I pictured are maybe 2mm wide at the bottom edge, so not exactly thin. I think the solution is that they have a gradual taper in total blade width from the paper-thin tail toward the toe, and as the blade is closed, the scales are easily pushed apart by the blade if needed.

1356Likes

1356Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote